Programming and Operating Manual (Turning)

132 01/2017

Subroutines are called in a program (main or subprogram) with their names. To do this, a separate block is required.

Example:

If a subroutine is to be executed several times in succession, write the number of times it is to be executed in the block of

the call after the subroutine name under the

. A maximum of

are possible (P1 ... P9999).

Example:

; Subprogram call L785, 3 cycles

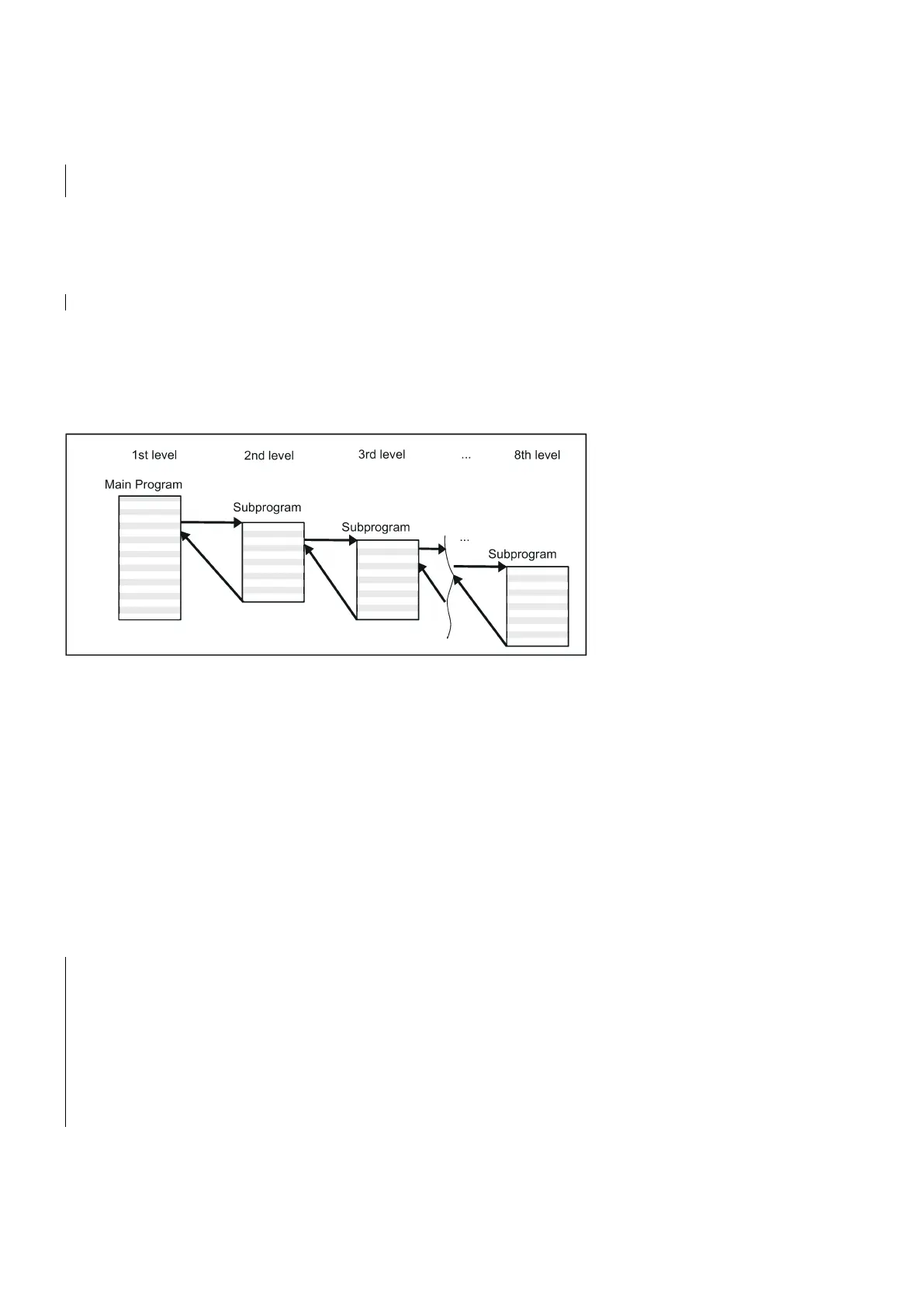

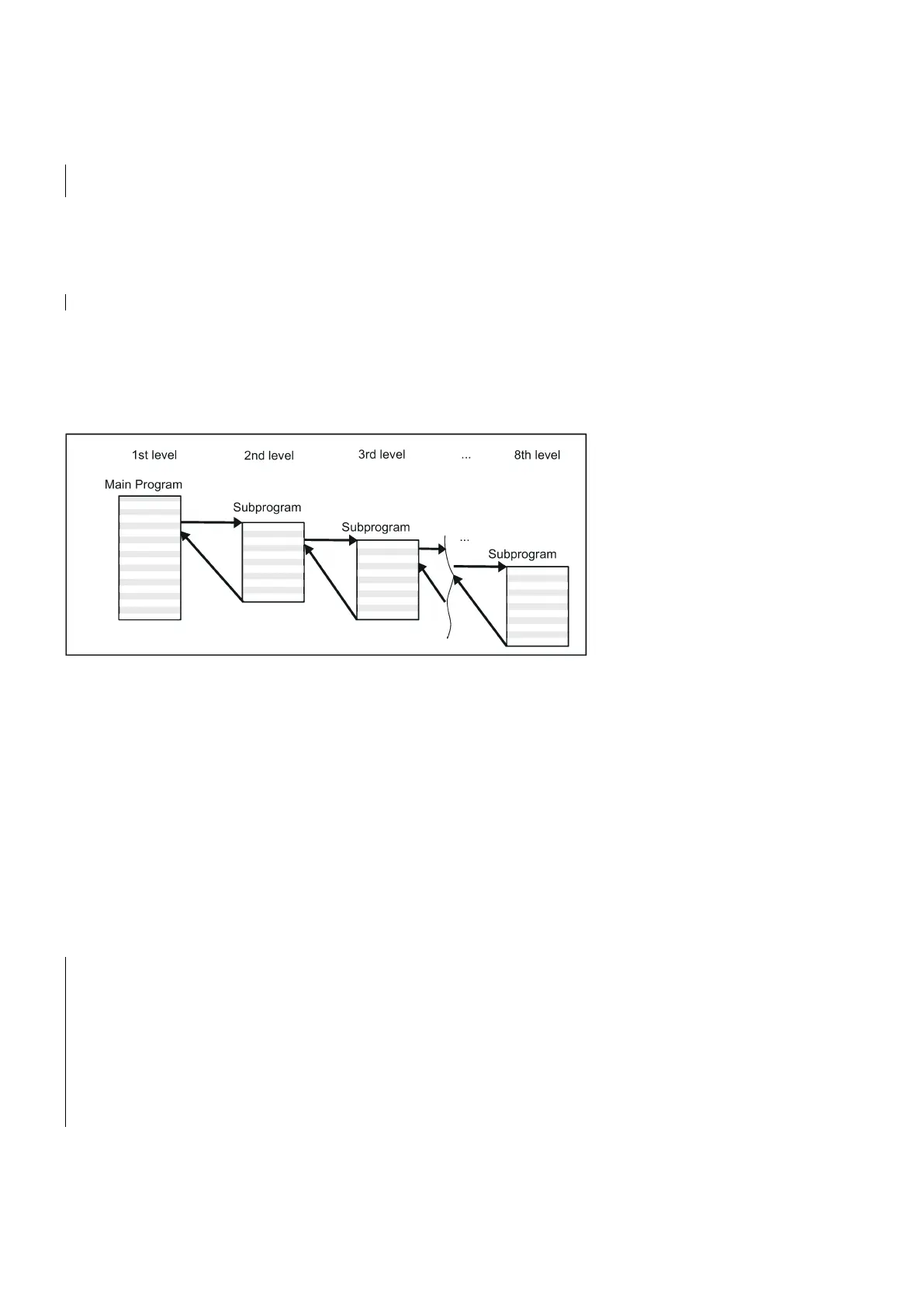

Subroutines can also be called from a subroutine, not only from a main program. In total, up to

are

available for this type of nested call, including the main program level.

See the following illustration for execution with 8 program levels:

Modal G functions can be changed in the subroutine, e.g. G90 -> G91. When returning to the calling program, ensure that all

modal functions are set the way you need them to be.

Please make sure that the values of your arithmetic parameters used in upper program levels are not inadvertently changed

in lower program levels.

When working with SIEMENS cycles, up to 7 program levels are needed.

Calling machining cycles (turning)

Functionality

Cycles are technology subroutines that realize a certain machining process. Adaptation to the particular problem is

performed directly via supplying parameters/values when calling the respective cycle.

N10 DEF REAL RTP, RFP, SDIS, DP, DTB

N50 CYCLE83(110, 90, 0, -80, 0, -10, 0,

0, 0, 0, 1, 0)

;Call of cycle 83, transfer values directly,

separate block

N70 RTP=100 RFP= 95.5 SDIS=2.4, DP=-20,

DTB=3

;Set transfer parameters for cycle 82

N80 CYCLE82(RTP, RFP,SDIS, DP, , DTB)

;Call of cycle 82, separate block

Loading...

Loading...