Programming and Operating Manual (Turning)

228 01/2017

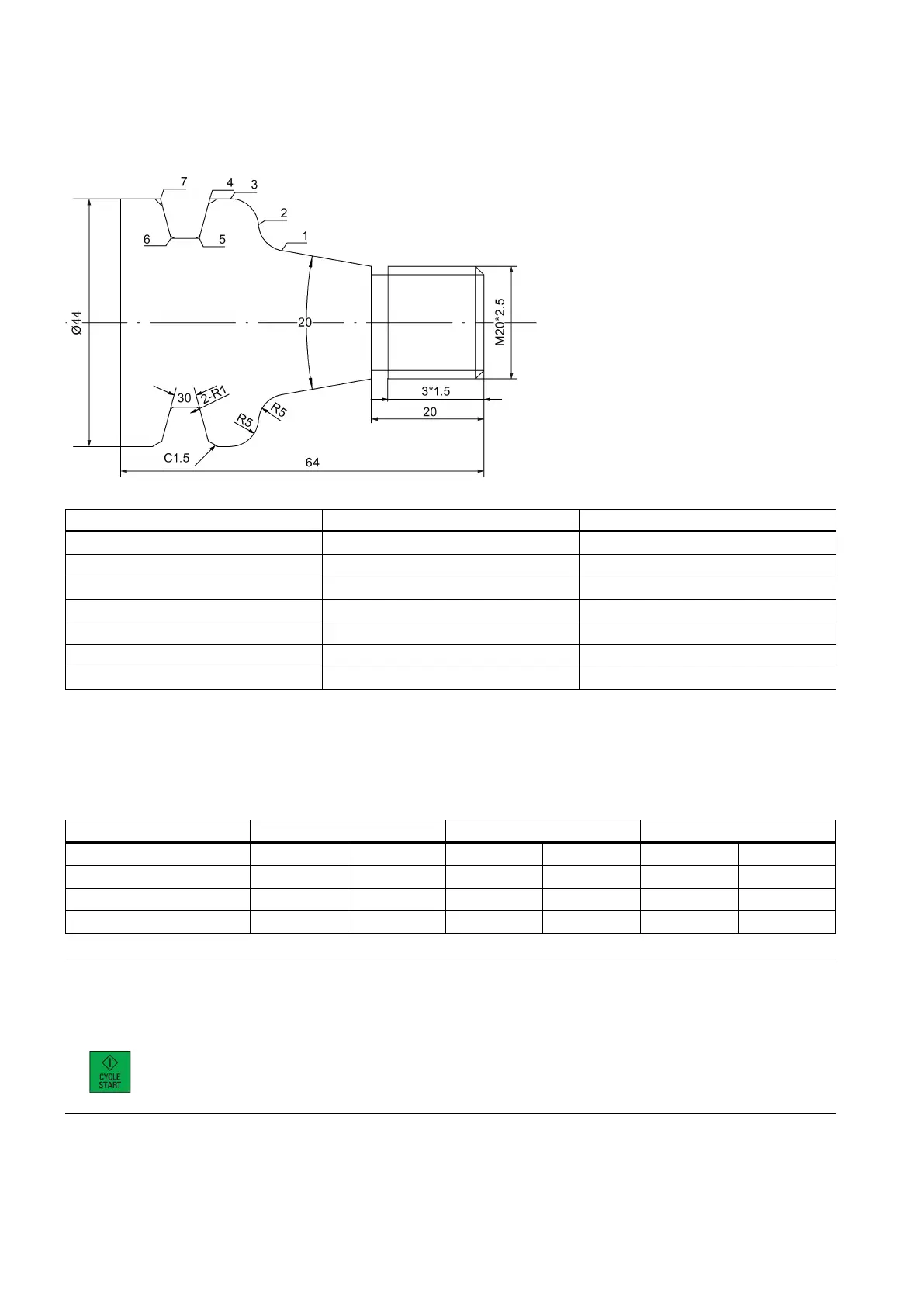

Programming for roughing, grooving and threading (Example 3)

Workpiece drawing (unit: mm)

Coordinates of key machining points

1 25.596 -35.868

Blank material: aluminum bar

Blank diameter: 45 mm

Blank length: 100 mm (machining limit along the Z axis: Z-68; three-jaw chuck clamping length: 25 mm)

When programming in ISO mode, you need to set the H numbers of T1, T3, and T4 to 1, 3, and 4 in the tool list

respectively. Three tools are required for the recommended program in ISO mode given later. You need to measure

them before machining. M00 is to stop program execution after cutting is over for each tool. To continue executing the

program, you need to press the following key on the MCP:

• Cut the workpiece manually after machining is over.

Loading...

Loading...