Programming and Operating Manual (Turning)

186 01/2017

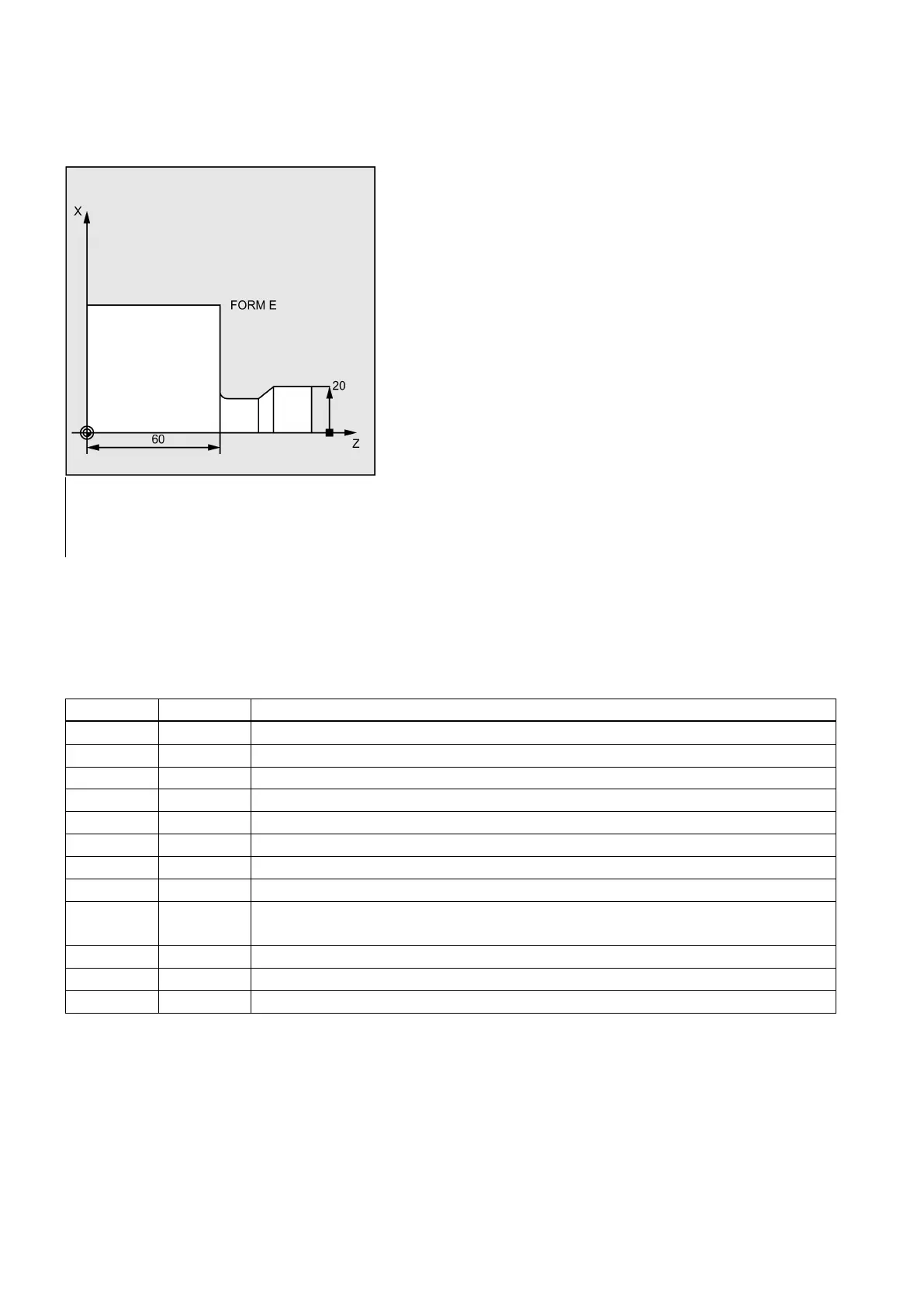

Programming example: Undercut form E

This program can be used to program an undercut of form E.

N10 T1 D1 S300 M3 G95 F0.3

; Specification of technology values

; Selection of starting position

N30 CYCLE94(20, 60, "E",)

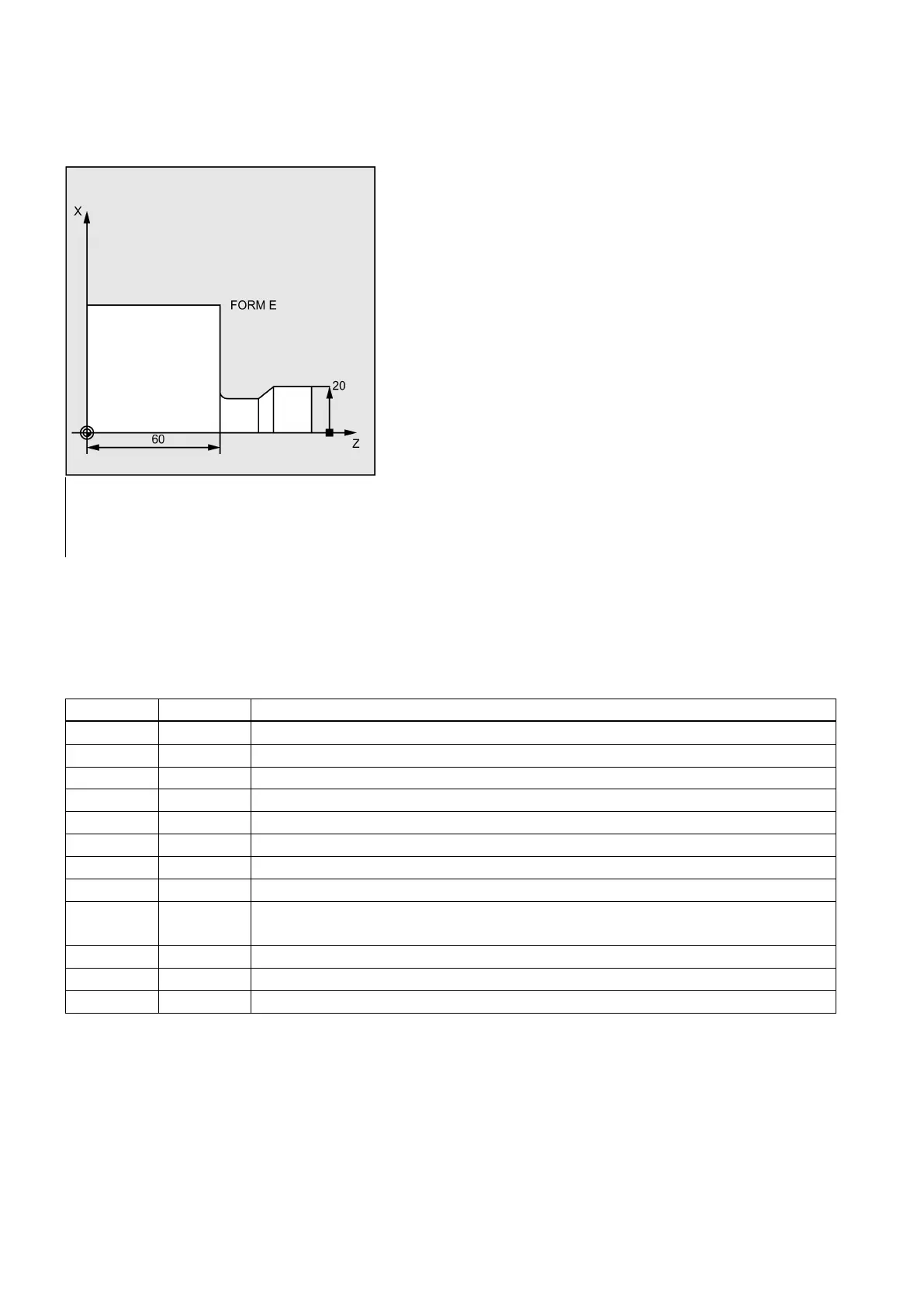

Cutting with relief cut - CYCLE95

Programming

CYCLE95 (NPP, MID, FALZ, FALX, FAL, FF1, FF2, FF3, VARI, DT, DAM, _VRT)

Name of contour subroutine

Infeed depth (enter without sign)

Finishing allowance in the longitudinal axis (enter without sign)

Finishing allowance in the transverse axis (enter without sign)

Finishing allowance suitable for contour (enter without sign)

Feedrate for roughing without relief cut

Feedrate for plunging into relief cut elements

Feedrate for finishing cut

VARI REAL Machining type

Range of values: 1 ... 12

Dwell time fore chip breaking when roughing

Path length after which each roughing step is interrupted for chip breaking

Lift-off distance from contour when roughing, incremental (to be entered without sign)

Using the rough turning cycle, you can produce a contour, which has been programmed in a subroutine, from a blank by

paraxial stock removal. The contour may contain relief cut elements. With this cycle, It is possible to machine

internal/external contours by using face/longitudinal machining. The technology can be freely selected (roughing, finishing,

complete machining). When roughing the contour, paraxial cuts from the maximum programmed infeed depth are

programmed and burrs are also removed parallel to the contour after an intersection point with the contour has been

reached. Roughing is performed up to the final machining allowance programmed.

Loading...

Loading...