Programming and Operating Manual (Turning)

01/2017

259

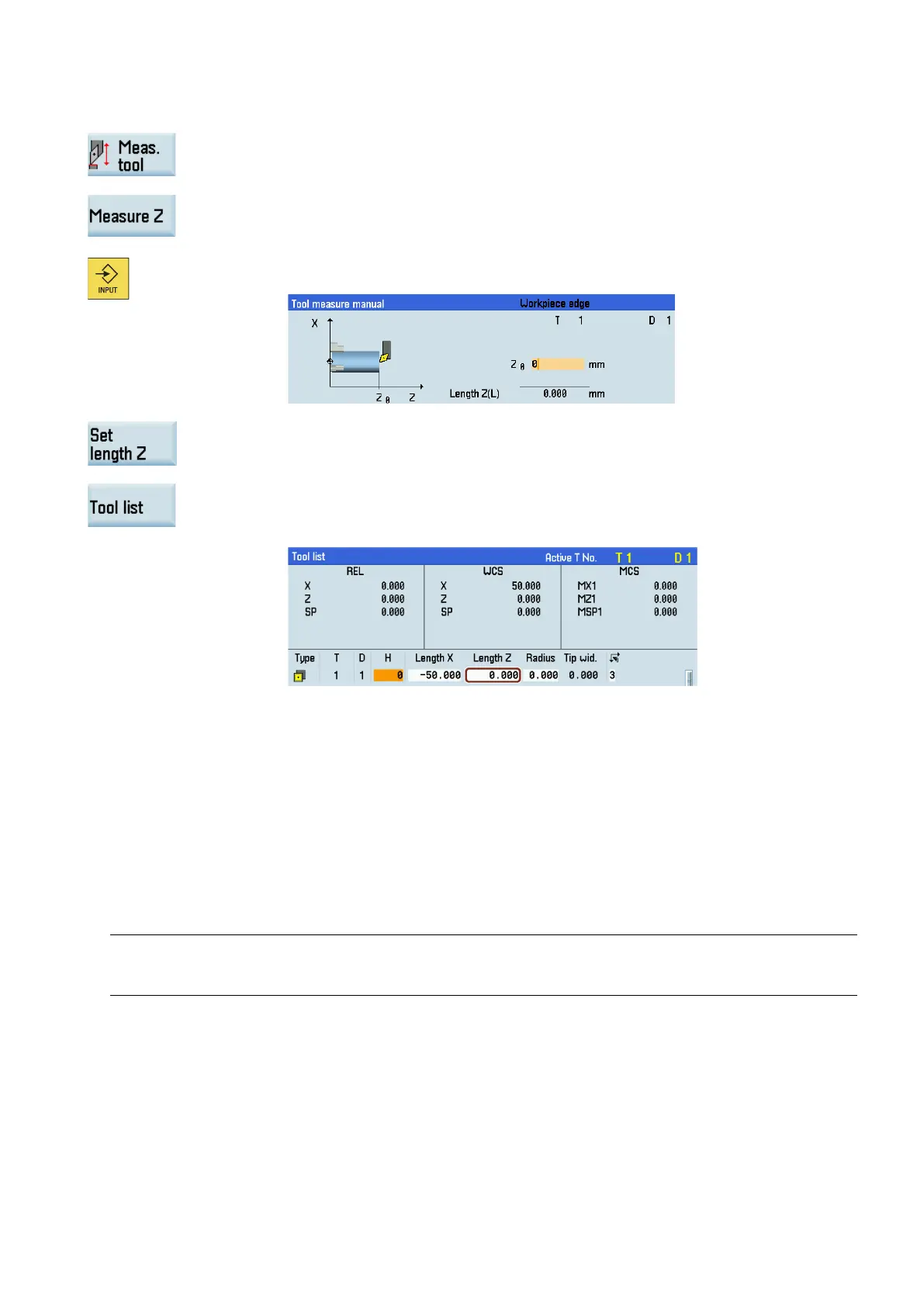

Measuring the Z axis of the tool

Open the manual tool measurement window.

Press this vertical softkey to measure the tool in the Z d

irection.

Enter the distance between the tool

tip and the workpiece edge in the "Z0" field, for exam-

ple, "0". (This value is the thickness of a setting block if it is used.)

Press this softkey and then the system calculates and enters the offset in the geometry

input field of the currently active tool automatically.

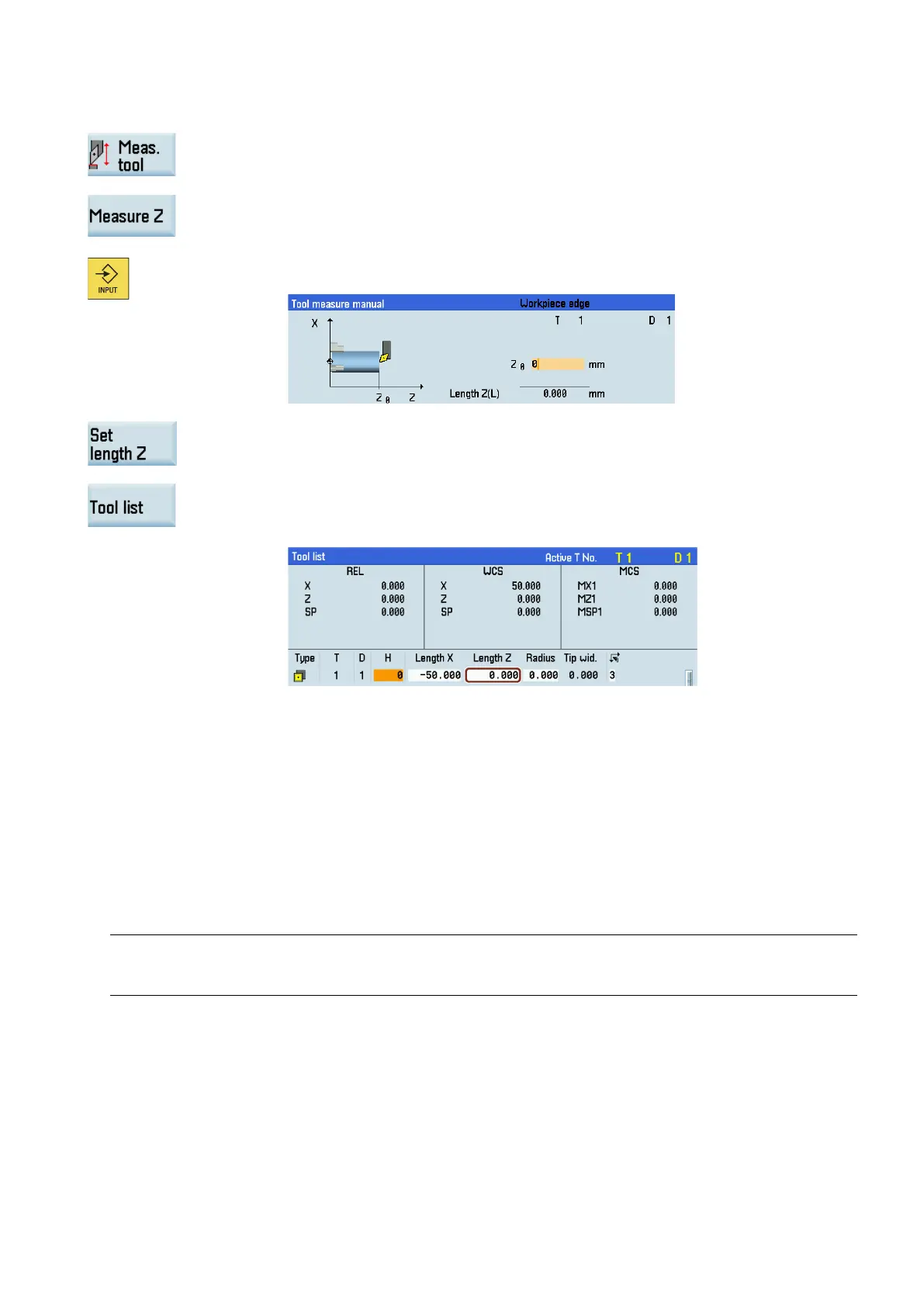

Press this softkey and you can see that the compensation data values have been automat

i-

cally added to the tool data.

Repeat the above steps to finish measuring all the tools.

Activating the contour handwheel via the NC program

The contour handwheel function can

help you with the first cutting test after you create a new NC program. When you have

activated this function, you can control the feedrate of path and synchronized axes via a handwheel in "AUTO" or "MDA"

mode. This section only introduces how to activate the contour handwheel via the NC program. For how to activate this

function via the PLC interfaces, see the SINUMERIK 808D/SINUMERIK 808D ADVANCED Function Manual.

● You must not select fixed feedrate, dry-run feedrate, thread cutting, or tapping.

Note

If you have not programmed the feedrate in the previous blocks, the control system prompts an alarm which indicates the

absence of feedrate.

● The axes have been referenced. For more information about how to reference the axes, see Chapter "Switching on and

referencing (Page 18)".

● The option of "Contour handwheel" is activated with a license key. For more information about how to activate an option,

see the SINUMERIK 808D/SINUMERIK 808D ADVANCED Commissioning Manual.

● You have assigned the handwheel to the first geometric axis and activated it. For more information, see Section

"Assigning the handwheel through the MCP (Page 24)".

Loading...

Loading...