Programming and Operating Manual (Turning)

28 01/2017

Measuring the tool manually (with the Y axis)

Note

If you have configured the Y axis and activa

ted it, proceed through the steps below to measure axes X, Y and Z of the tool.

For more information about how to configure the Y axis, see the SINUMERIK 808D/SINUMERIK 808D ADVANCED

Commissioning Manual.

Operating sequence

Measuring the X axis of the tool

Select the machining operating area.

Switch to "MDA" mode and enter "SPOS=0" in the pro

gram editor window to fix the spindle.

Switch to handwheel control mode.

Select a suitable override feedrate.

Use the handwheel to move the tool to approach the workpiece and cut the surface of the

workpiece for about 1 mm

along the Y axis. Then retract the tool along the Y axis.

Make sure you do not move the tool along the X axis afterwards.

Switch to "MDA" mode and continue to enter "SPOS=180" in the program editor window.

Press this key to rotate the spindle 180 degrees.

Measure the distance between the two cutting surfaces machined in the previous steps with

a calliper.

Select the offset operating area.

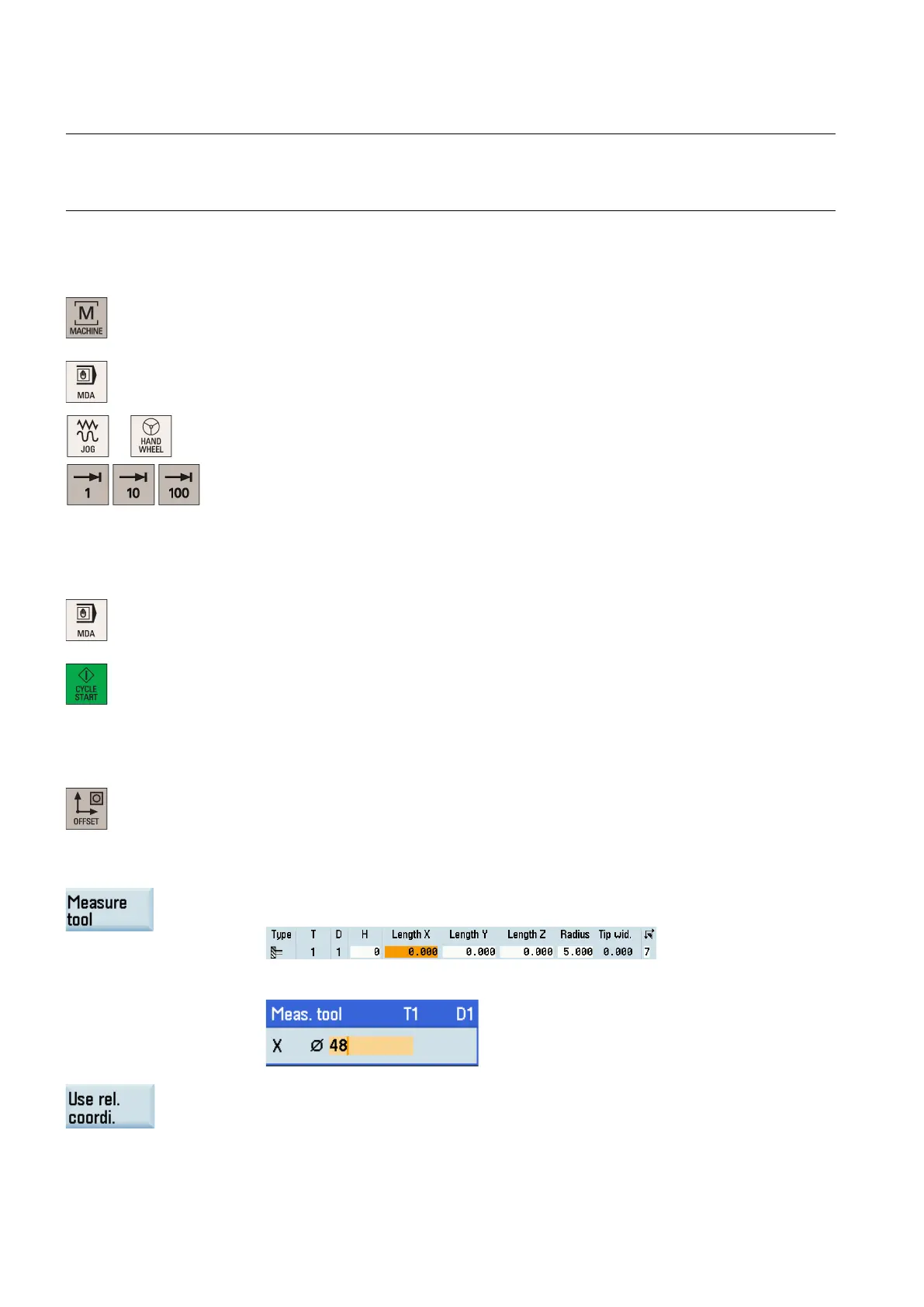

Press the alphabetic key <X> or proceed through the following method to open the window

for measuring the tool in the X direction:

Move the cursor to the input field for Length X with the cursor keys and then press this sof

t-

Enter the distance measured in Step 9 in the input field, for example, 48.

If you desire to use the relative coordinate, press this softkey.

Loading...

Loading...