Programming and Operating Manual (Turning)

01/2017

39

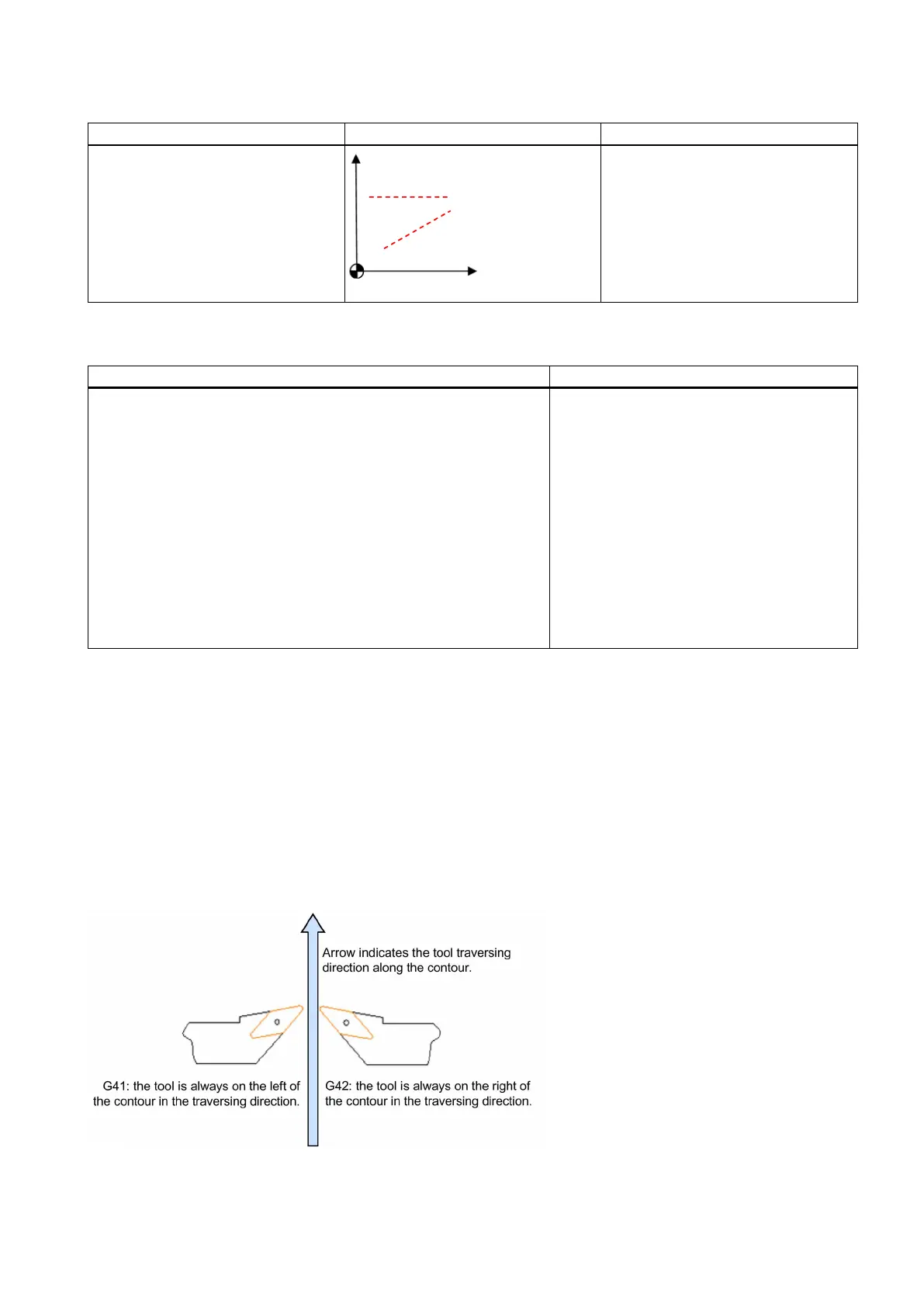

When G00 is active in the program, the

axis will traverse at the maximum axis

speed in a straight line.

Straight line in any direction

N10 G18 G90 G54 G71

N20 T1 D1

N30 S5000 M3 G95 F0.3

N40

N50 G01

N60

N70

For more information, see Section "Linear interpolation with rapid traverse: G0 (Page 85)".

Tool and traverse (T, D, F, G94/G95, S, M3/M4, G01)

A new tool can be selected with the "T" command, and the "D" command

is used to activate the tool length offset.

The feedrate is defined with "F". G94 F defines feedrate in terms of time

(mm/min) and G95 F defines feedrate in terms of spindle revolutions

(mm/rev).

The spindle speed is defined with "S". The spindle direction is defined

with M3 (clockwise) and M4 (counter-clockwise).

When G01 is active in the program, the axis traverses at the pro-

grammed feedrate (as defined by G94 F or G95 F) in a straight line.

N10 G18 G90 G54 G71

N20

N30

N40 G00 X50 Z5

N50

N60 Z5

N70 G00 Z500 Z200

For more information, see sections as follows:

● Tool T (turning) (Page 114)

● Tool offset number D (turning) (Page 115)

● Feedrate F (Page 86)

● Spindle speed S, directions of rotation (Page 101)

● Linear interpolation with feedrate: G1 (Page 87)

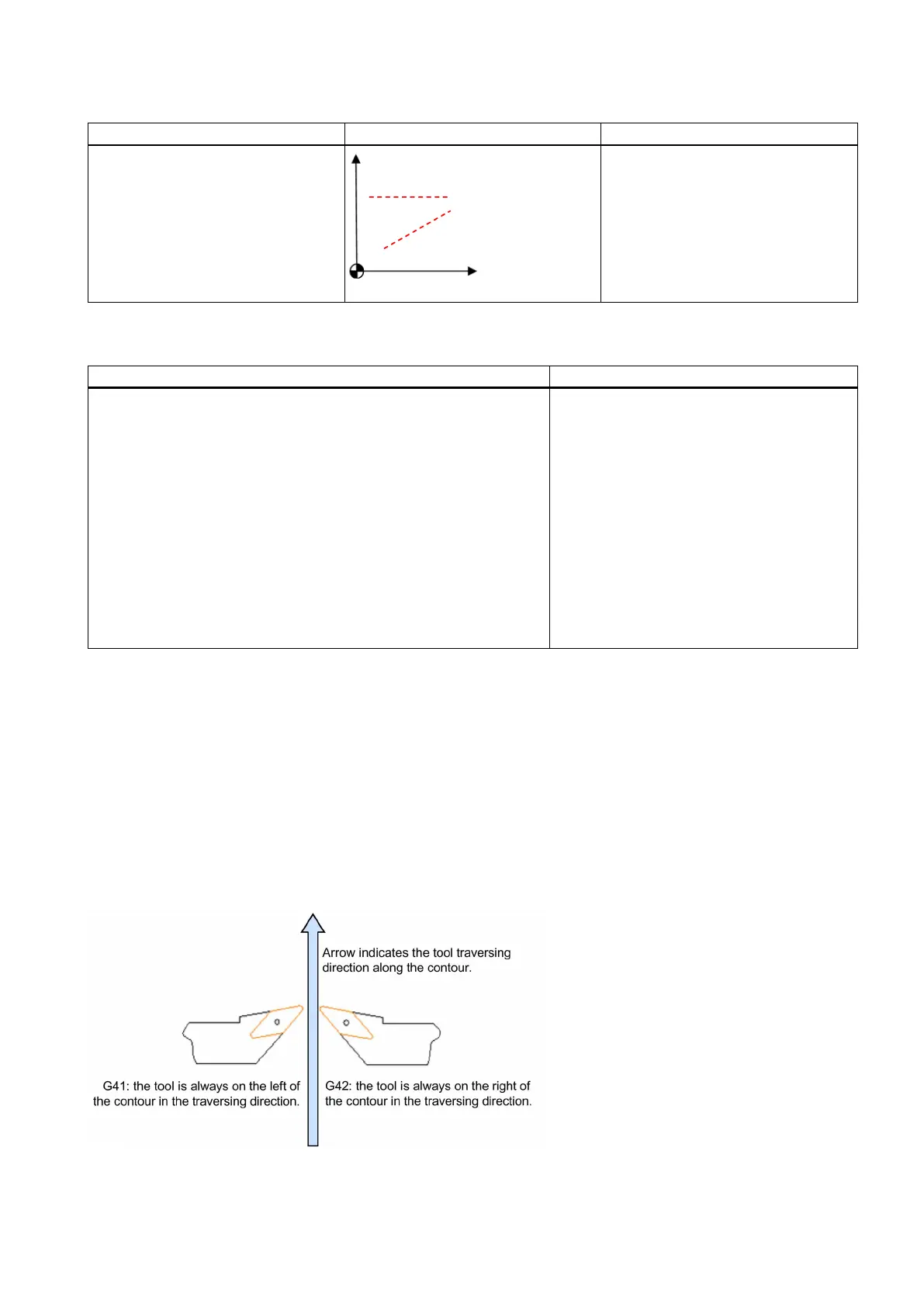

Tool radius compensation (G40, G41/G42)

The tool radius compensation can be activated (G41/G42) or deactivated (G40) in contour programming.

● G41: tool radius compensation to the left of the contour

● G42: tool radius compensation to the right of the contour

● G40: tool radius compensation off

Loading...

Loading...