EM-93

ENGINE MECHANICAL - Cylinder Block

INSPECTION OF CYLINDER BLOCK

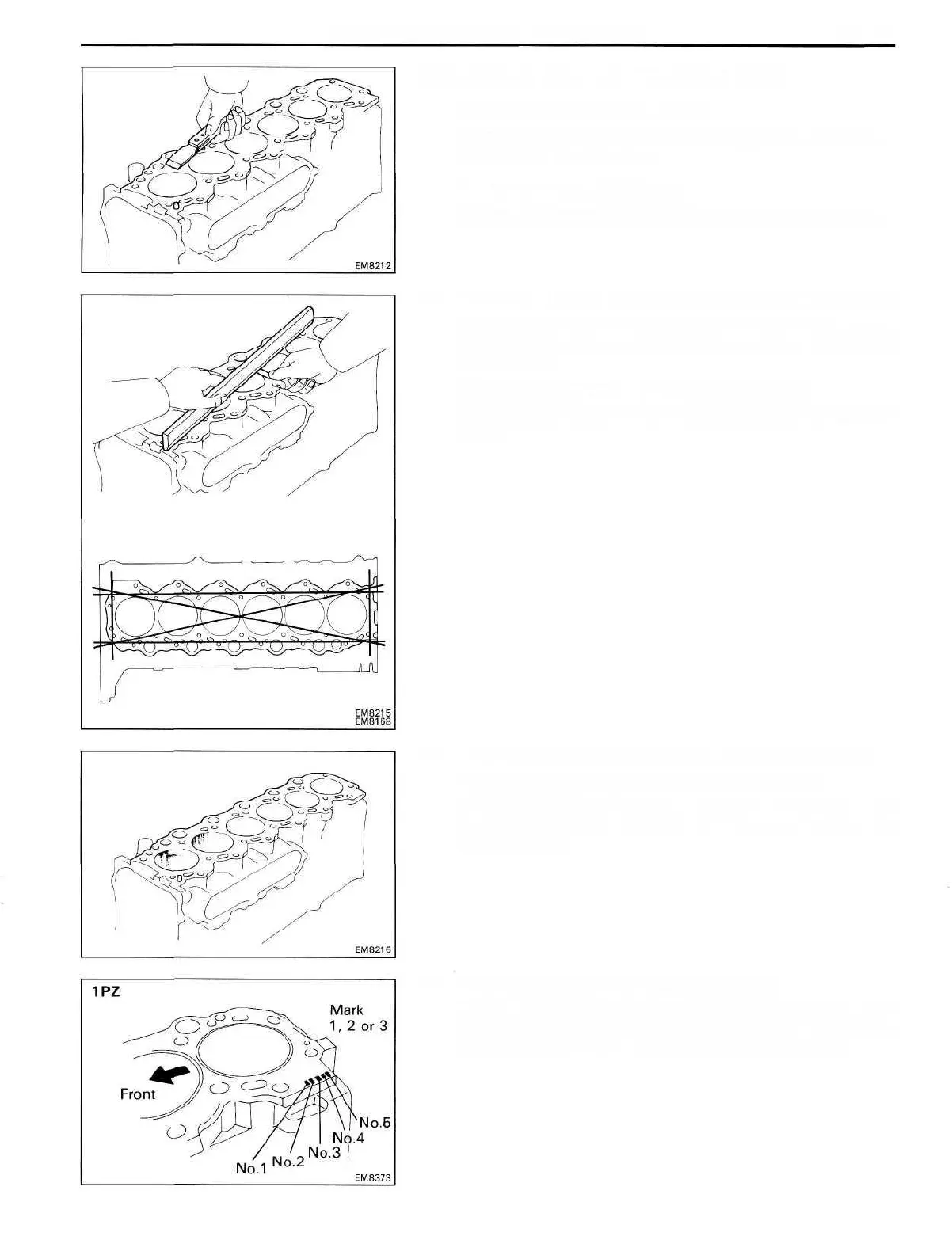

1. REMOVE GASKET MATERIAL

Using a gasket scraper, remove all the gasket material from

the cylinder block surface.

2. CLEAN CYLINDER BLOCK

Using a soft brush and solvent, clean the cylinder block.

3. INSPECT TOP OF CYLINDER BLOCK FOR FLATNESS

Using a precision straight edge and thickness gauge,

measure the surfaces contacting the cylinder head gasket

for warpage.

Maximum warpage: 0.20 mm (0.0079 in.)

If warpage is greater than maximum, replace the cylinder

block.

4. INSPECT CYLINDER FOR VERTICAL SCRATCHES

Visually check the cylinder for vertical scratches.

If deep scratches are present, rebore all five (1PZ) or six

(1HZ and 1HD-T) cylinders. If necessary, replace the

cylinder block.

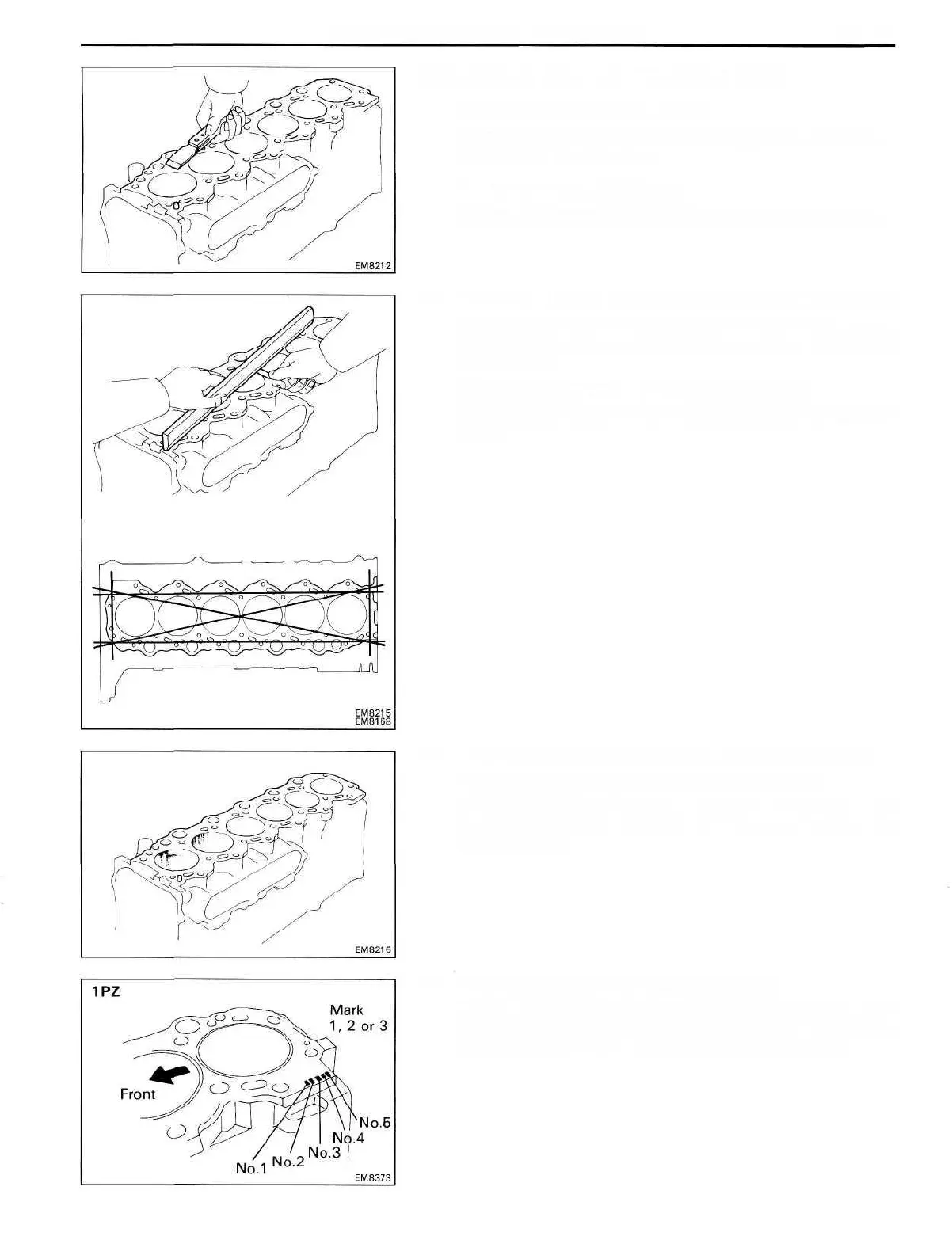

5. INSPECT CYLINDER BORE DIAMETER

HINT: There are three sizes of the standard cylinder bore

diameter, marked "1", "2" and "3" accordingly. The mark is

stamped on the upper left rear of the cylinder block.

Loading...

Loading...