TURBOCHARGER SYSTEM Turbocharger TC-13

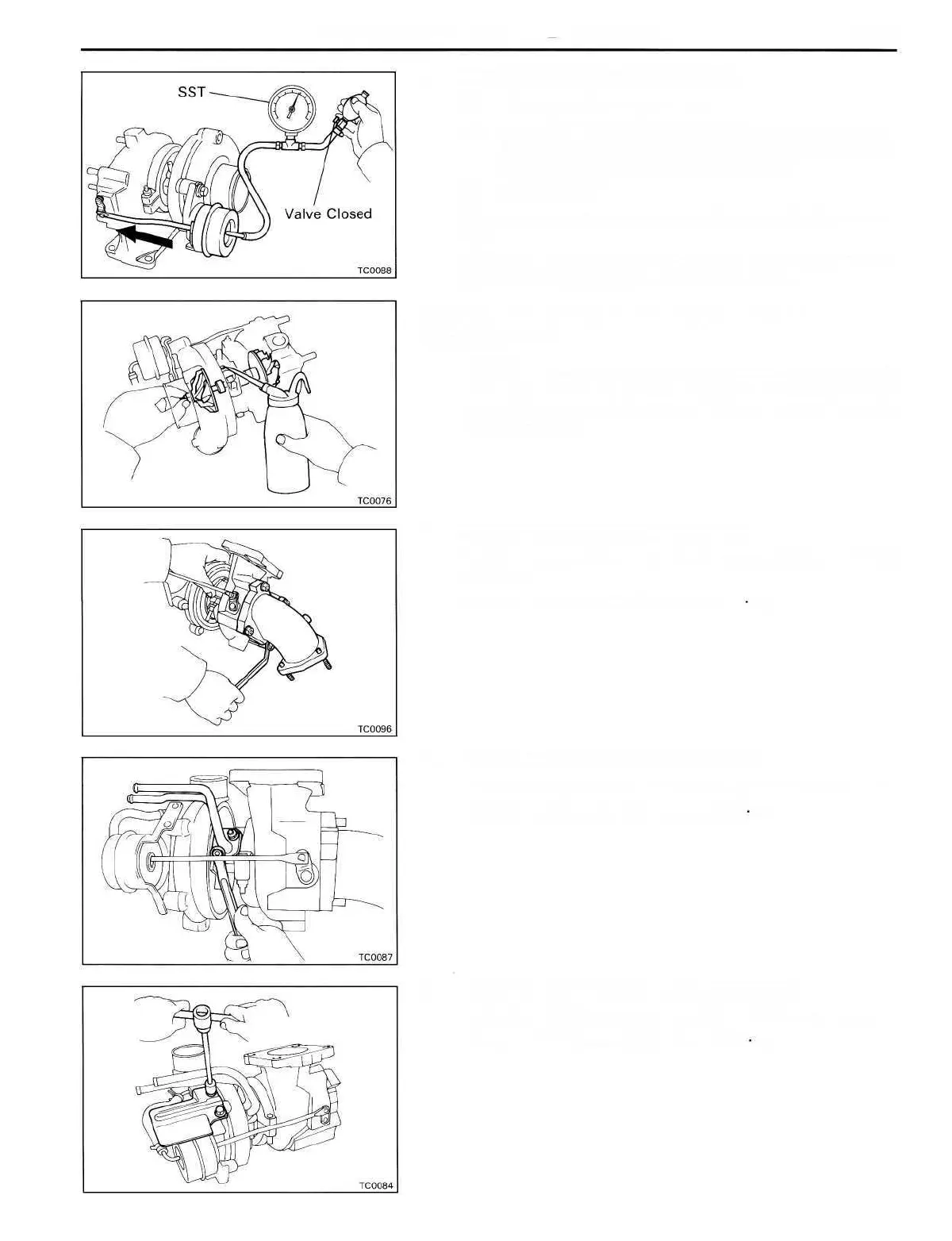

4. INSPECT ACTUATOR OPERATION

(a) Disconnect the actuator hose.

(b) Using SST (turbocharger pressure gauge), apply ap-

prox. 0.92 kg/cm

2

(13.1 psi, 90 kpa) of pressure to the

actuator and check that the rod moves.

SST 09992-00241

If the rod does not move, replace the turbocharger assem-

bly.

NOTICE: Never apply more than 1.05 kg/cm

2

(14.9

psi, 103 kPa) of pressure to the actuator.

INSTALLATION OF TURBOCHARGER

(See page TC-9)

NOTICE: After replacing the turbocharger assembly,

pour approx. 20 cc (1.2 cu in.) of new oil into the oil

inlet and turn the impeller wheel by hand to splash oil

on the bearing.

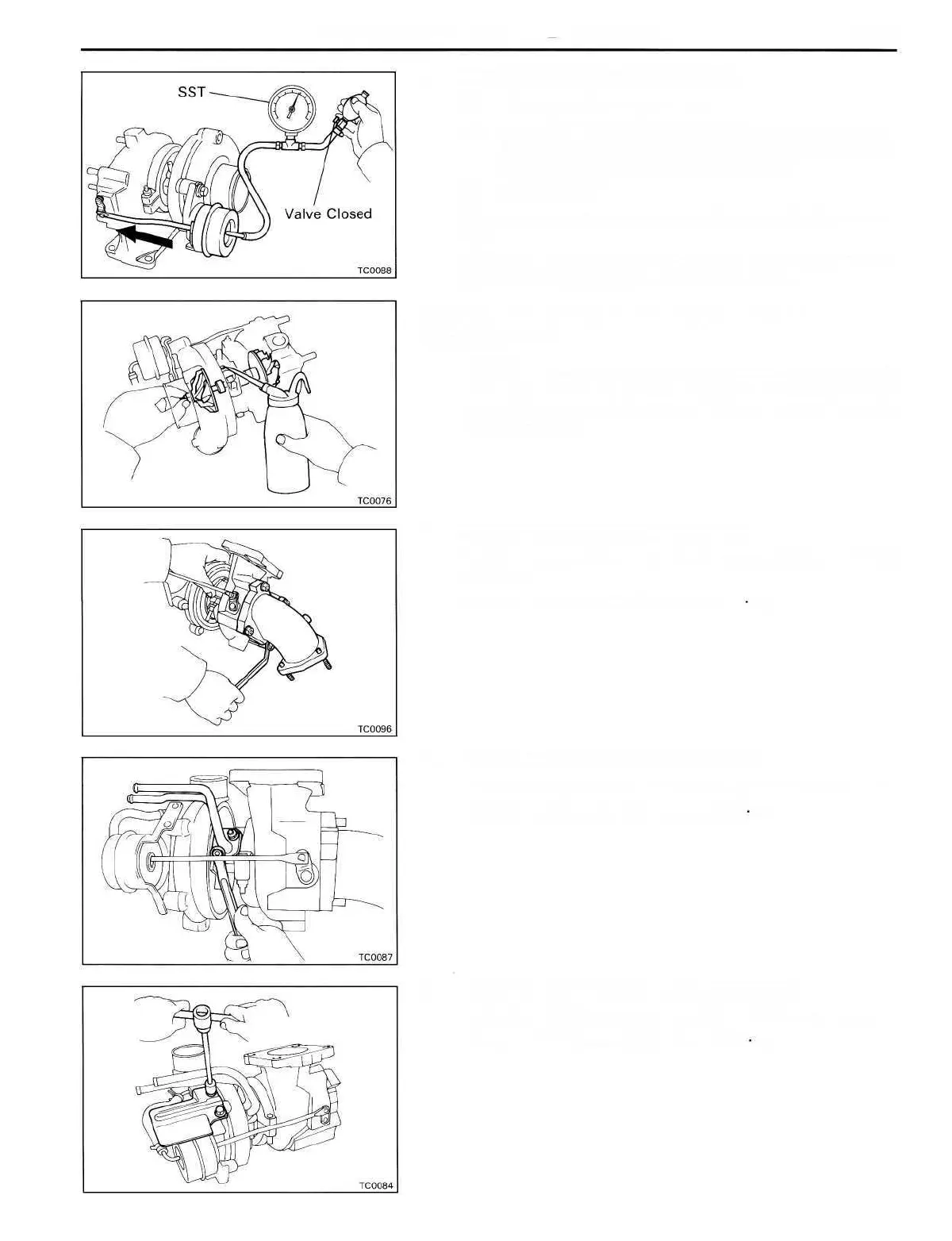

1. INSTALL TURBINE OUTLET ELBOW

Install a new gasket and the turbine outlet elbow with the

four nuts.

Torque: 530 kg-cm (38 ft-lb, 52 Nm)

2. INSTALL NO.1 TURBO WATER PIPE

Install a new gasket and the water pipe with the two nuts.

Torque: 80 kg-cm (69 in.-Ib, 7.8 Nm)

3. INSTALL NO.2 TURBO HEAT INSULATOR

Install the No.2 turbo heat insulator with the two bolts.

Torque: 80 kg-cm (69 in.-Ib, 7.8 Nm)

Loading...

Loading...