FU-3

FUEL SYSTEM Description

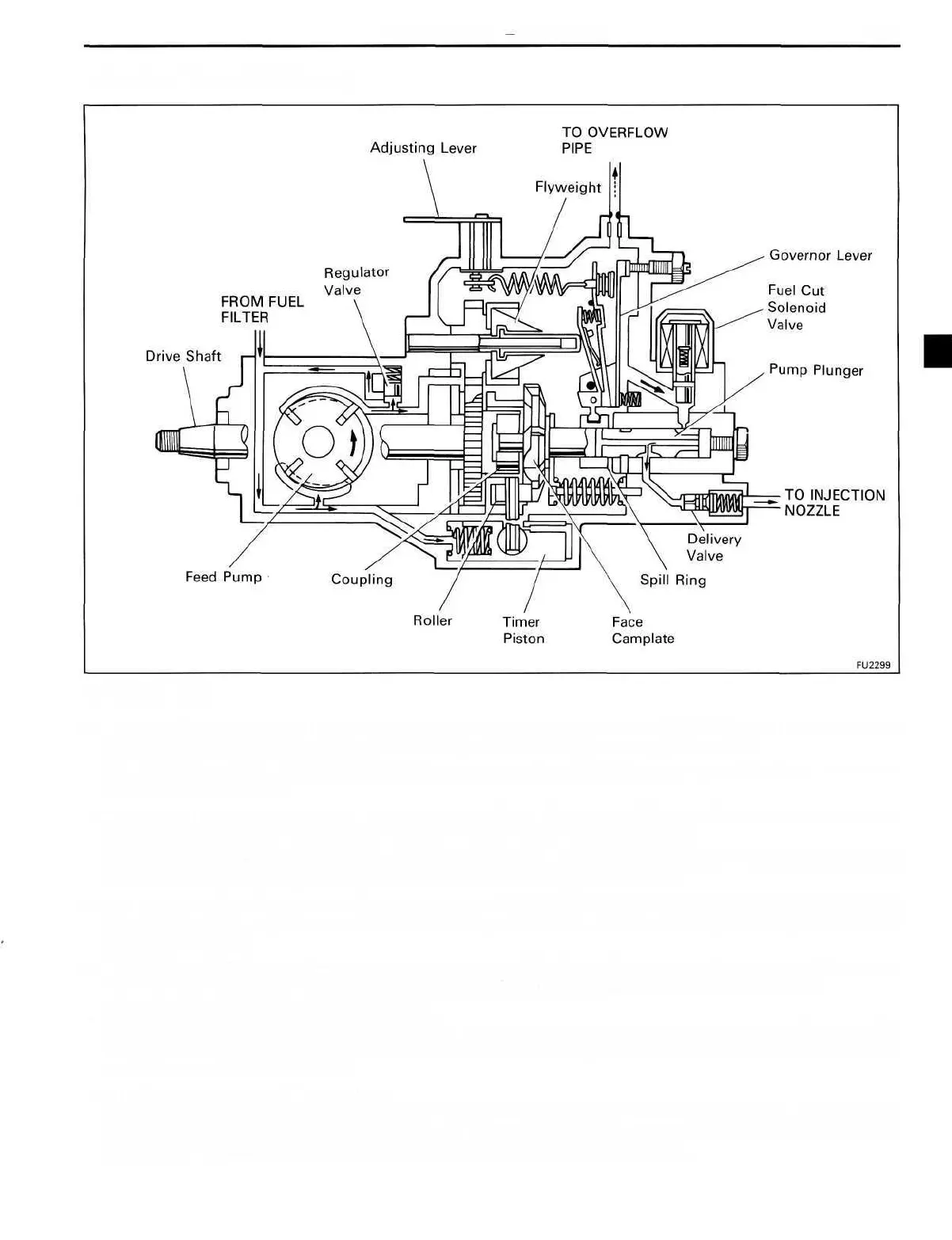

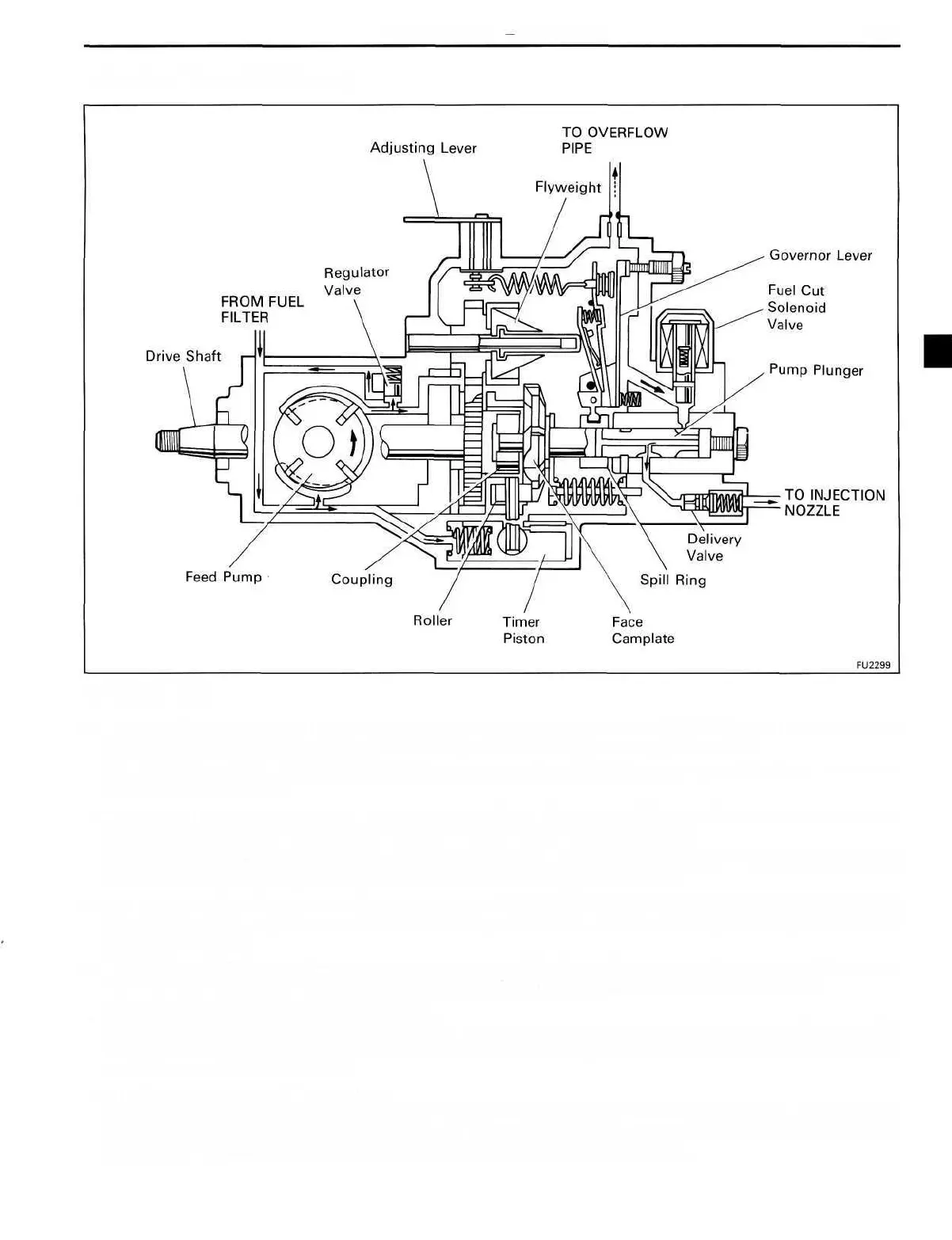

Injection Pump (VE Pump)

OPERATION

• The centrifugal force type feed pump takes up a fixed volume of fuel with each turn. The fuel expulsion

pressure from the feed pump is controlled by operation of the pressure regulator valve.

• Fuel is sent from the outlet side of the feed pump, through the hole in the upper part of the feed pump cover

and into the pump body.

• The pump plunger also rotates as it moves up and down. After the fuel is drawn in, it is distributed under

pressure to the delivery valve of each cylinder according to the injection order.

• The centrifugal force type all speed governor installed in the upper part of the injection pump moves the spill

ring obstructing the plunger spill port and controls the fuel injection volume.

• The hydraulic type timer installed in the lower part of the injection pump is operated by the fuel pressure of

the pump housing, and movement of the roller ring by the timer advances the injection angle and controls

the injection timing.

• The fuel cut solenoid valve is connected to the starter switch IG circuit, and when the starter switch is turned

to OFF, the current is cut off, the solenoid is de-energized, fuel is cut off and the engine stops.

• High Altitude Compensation (HAC) Device

Due to the decrease in atmospheric pressure at high altitudes, the air fuel ratio becomes more dense and the

smoke density increases. To prevent this, the device automatically reduces the fuel injection volume for full

loads in response to the altitude.

• Boost Compensator with turbocharger

The boost compensator is installed on the upper part of the governor of the injection pump. Turbocharged

air pressure moves the diaphragm and push rod up and down, this movement is conveyed to the spill ring

and the fuel injection volume increases according to the degree of movement.

Loading...

Loading...