EM-94

ENGINE MECHANICAL - Cylinder Block

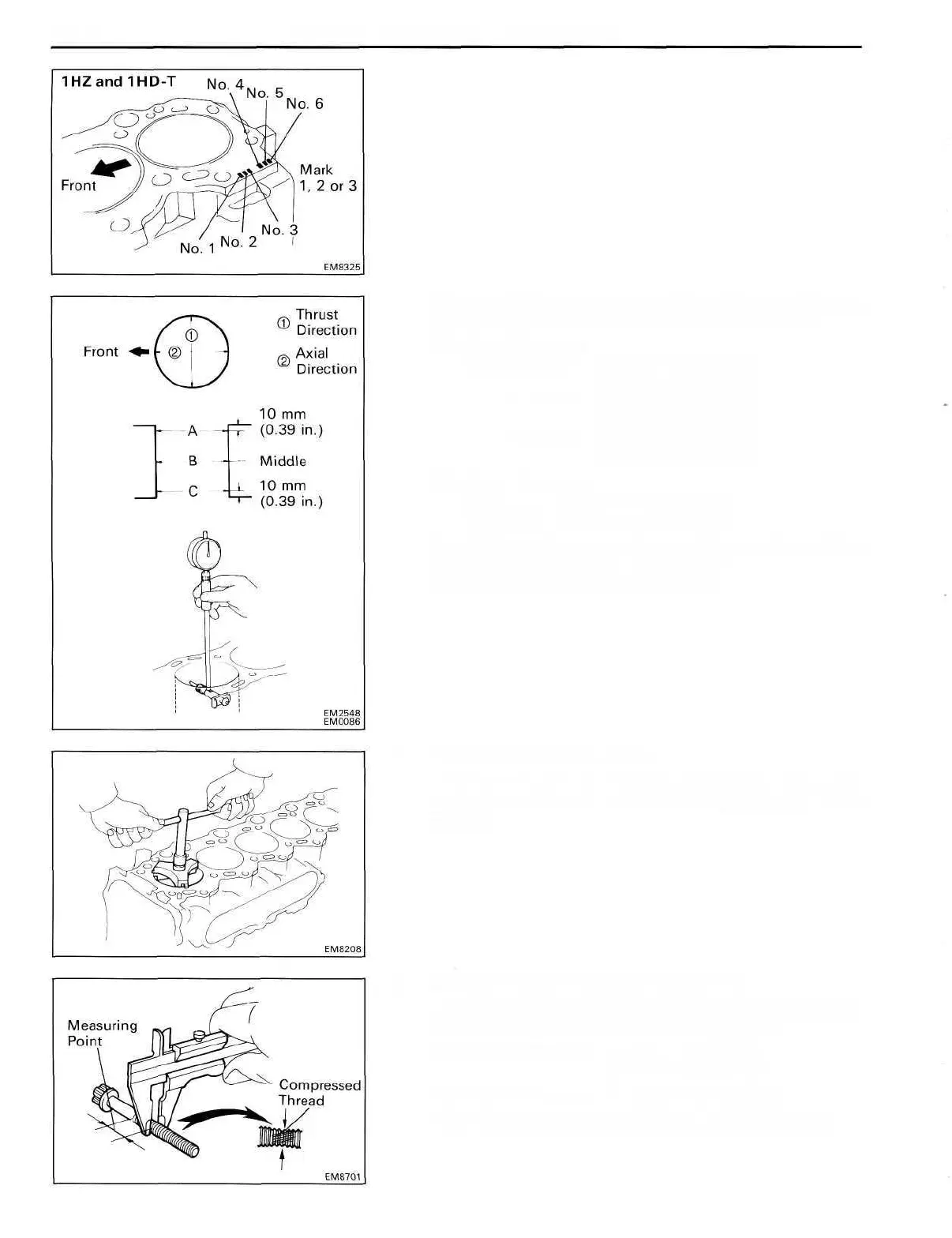

Using a cylinder gauge, measure the cylinder bore diameter

at positions A, B and C in the thrust axial directions.

Standard diameter:

STD Mark "1" 94.000-94.010 mm

(3.7008-3.7012 in.)

Mark "2" 94.010-94.020 mm

(3.7012-3.7016 in.)

Mark "3" 94.020 - 94.030 mm

(3.7016-3.7020 in.)

Maximum diameter:

STD 94.23 mm (3.7098 in.)

O/S 0.50 94.73 mm (3.7295 in.)

If the diameter is greater than maximum, rebore all five

(1 PZ) or six (1 HZ and 1 HD-T) cylinders.

If necessary, replace the cylinder block.

6. REMOVE CYLINDER RIDGE

If the wear is less than 0.2 mm (0.008 in.), use a ridge

reamer to machine the piston ring ridge at the top of the

cylinder.

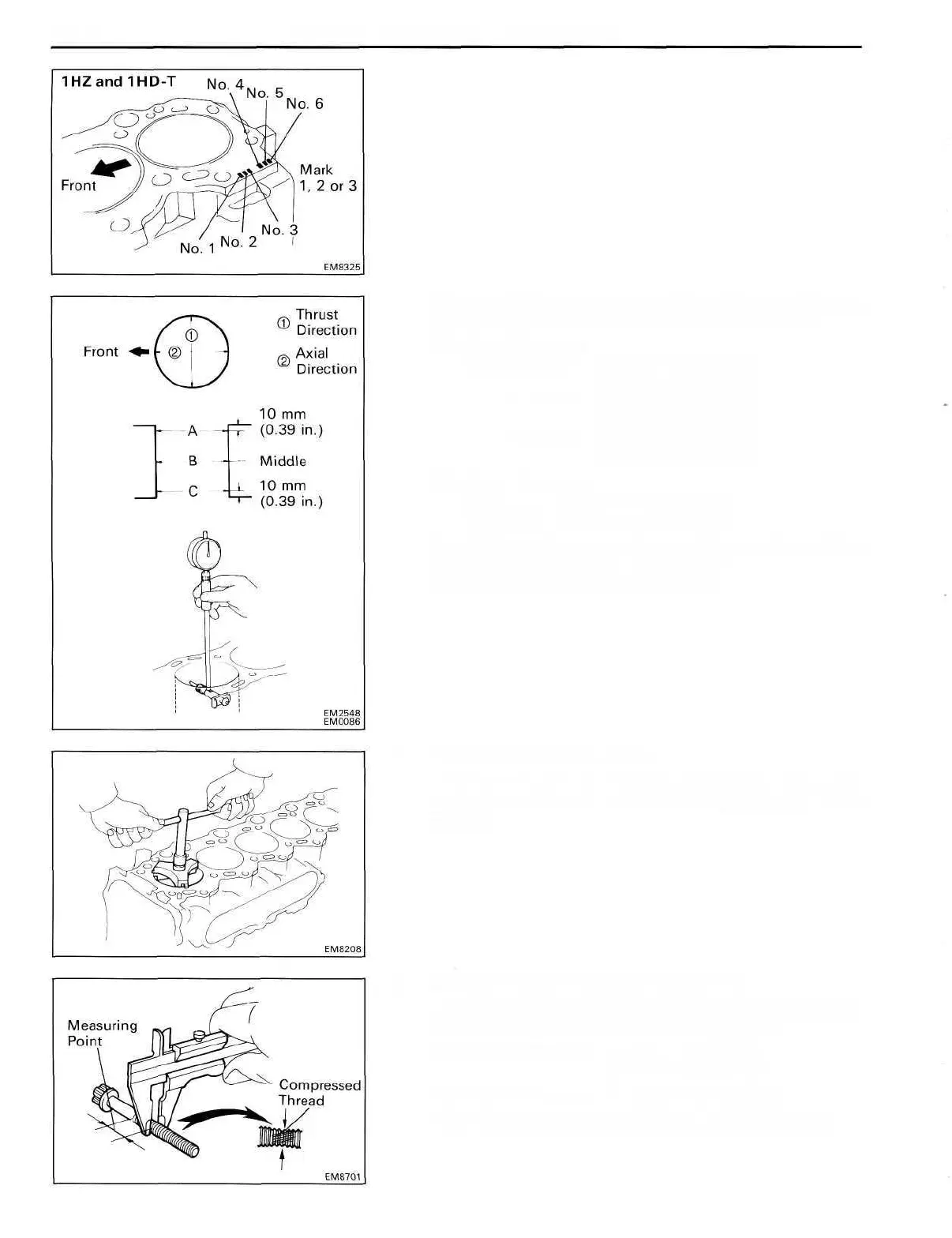

7. INSPECT MAIN BEARING CAP BOLTS

Using vernier calipers, measure the minimum diameter of

the compressed thread at the measuring point.

Standard diameter: 11.800-12.000 mm

(0.4646-0.4724 in.)

Minimum diameter: 11.50 mm (0.4528 in.)

If the diameter is less than minimum, replace the bolt.

Loading...

Loading...