EM-69

ENGINE MECHANICAL - Cylinder Head

14. INSPECT CAMSHAFTS AND BEARINGS

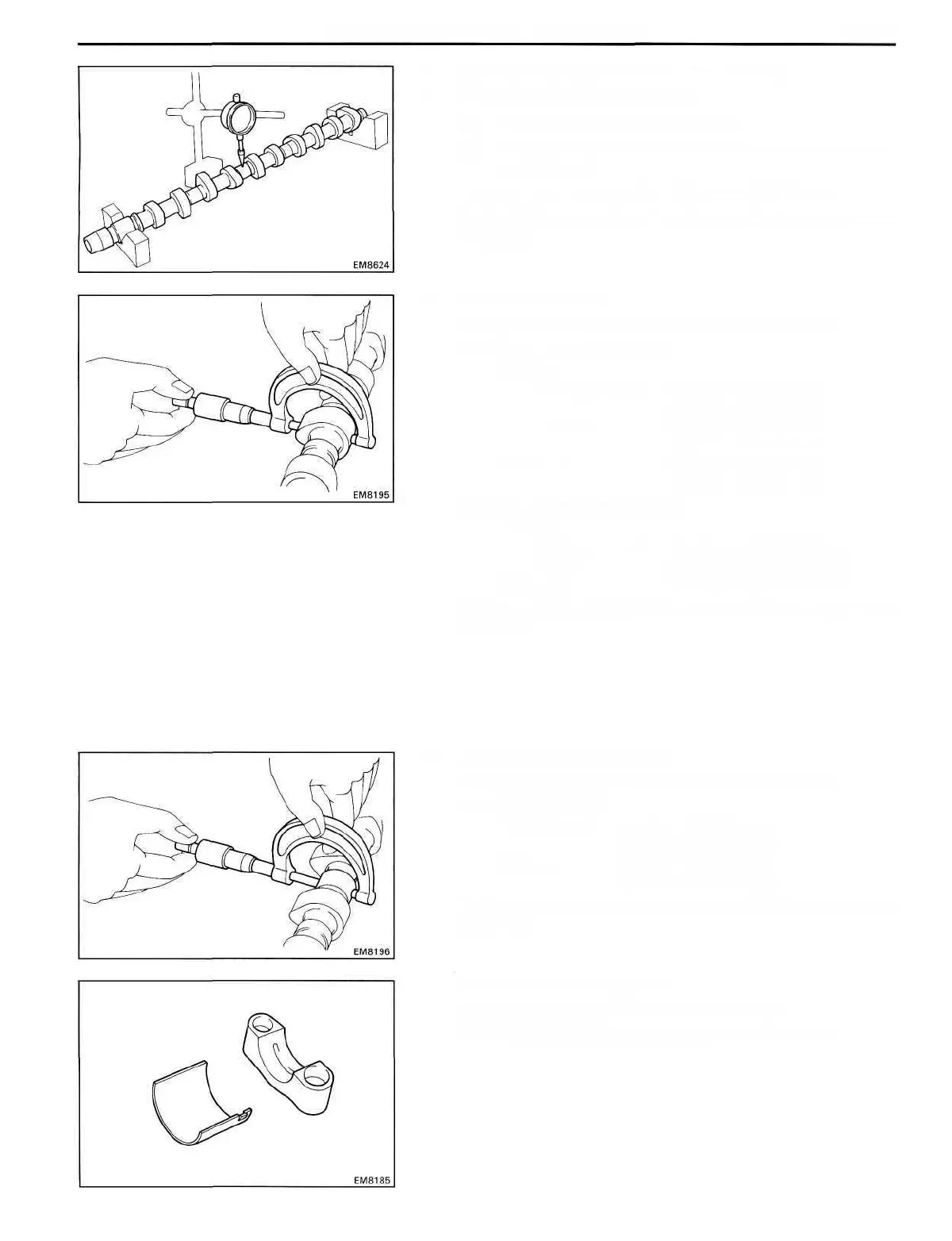

A. Inspect camshaft for runout

(a) Place the camshaft on V-blocks.

(b) Using a dial indicator, measure the circle runout at the

center journal.

Maximum circle runout: 0.10 mm (0.0039 in.)

If the circle runout is greater than maximum, replace the

camshaft.

B. Inspect cam lobes

Using a micrometer, measure the cam lobe height.

Standard cam lobe height:

Intake

1PZ and 1HZ 55.090-55.110 mm

(2.1689-2.1697 in.)

1 HD-T 54.440-54.460 mm

(2.1433-2.1441 in.)

Exhaust 55.940 - 55.960 mm

(2.2024-2.2031 in.)

Minimum cam lobe height:

Intake

IPZ and 1HZ 54.59 mm (2.1492 in.)

1H-D 53.94 mm (2.1236 in.)

Exhaust 55.44 mm (2.1827 in.)

If the cam lobe height is less than minimum, replace the

camshaft.

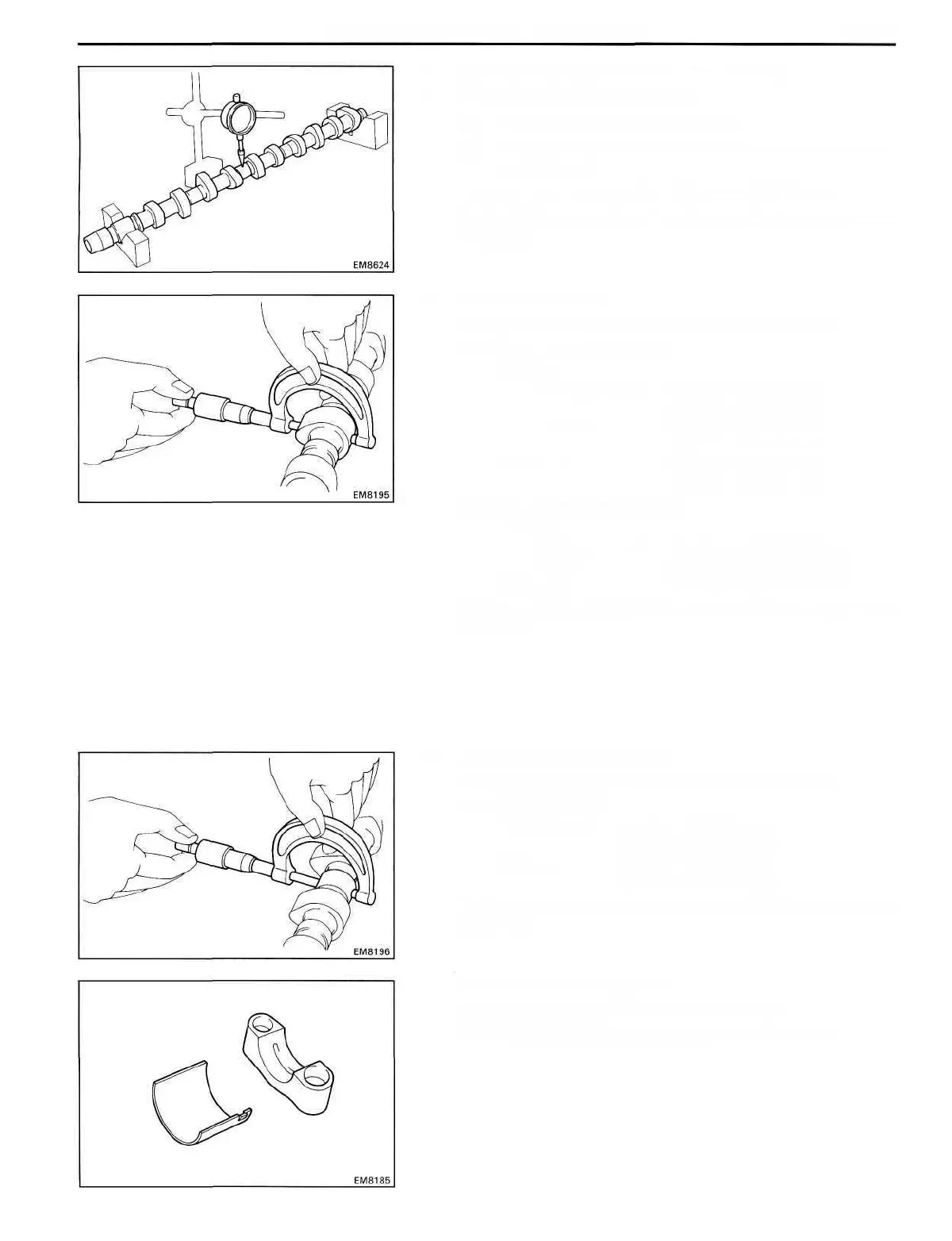

C. Inspect camshaft journals

Using a micrometer, measure the journal diameter.

Journal diameter:

No.1 journal 34.969-34.985 mm

(1.3767-1.3774 in.)

Others 27.986-27.988 mm

(1.1018-1.1023 in.)

If the journal diameter is not as specified, check the oil

clearance.

D. Inspect camshaft bearings

Check the bearings for flaking and scoring.

If the bearings are damaged, replace the bearings.

Loading...

Loading...