EM-19

ENGINE MECHANICAL - Engine Tune-Up

ADJUSTMENT OF VALVE CLEARANCE

HINT: Adjust the valve clearance while the engine is cold.

1. REMOVE INTAKE PIPE

(See step 6 on page EM-34)

2. REMOVE CYLINDER HEAD COVER

(See step 7 on page EM-35)

3. SET NO.1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley clockwise, and align its

groove with the timing gear cover groove.

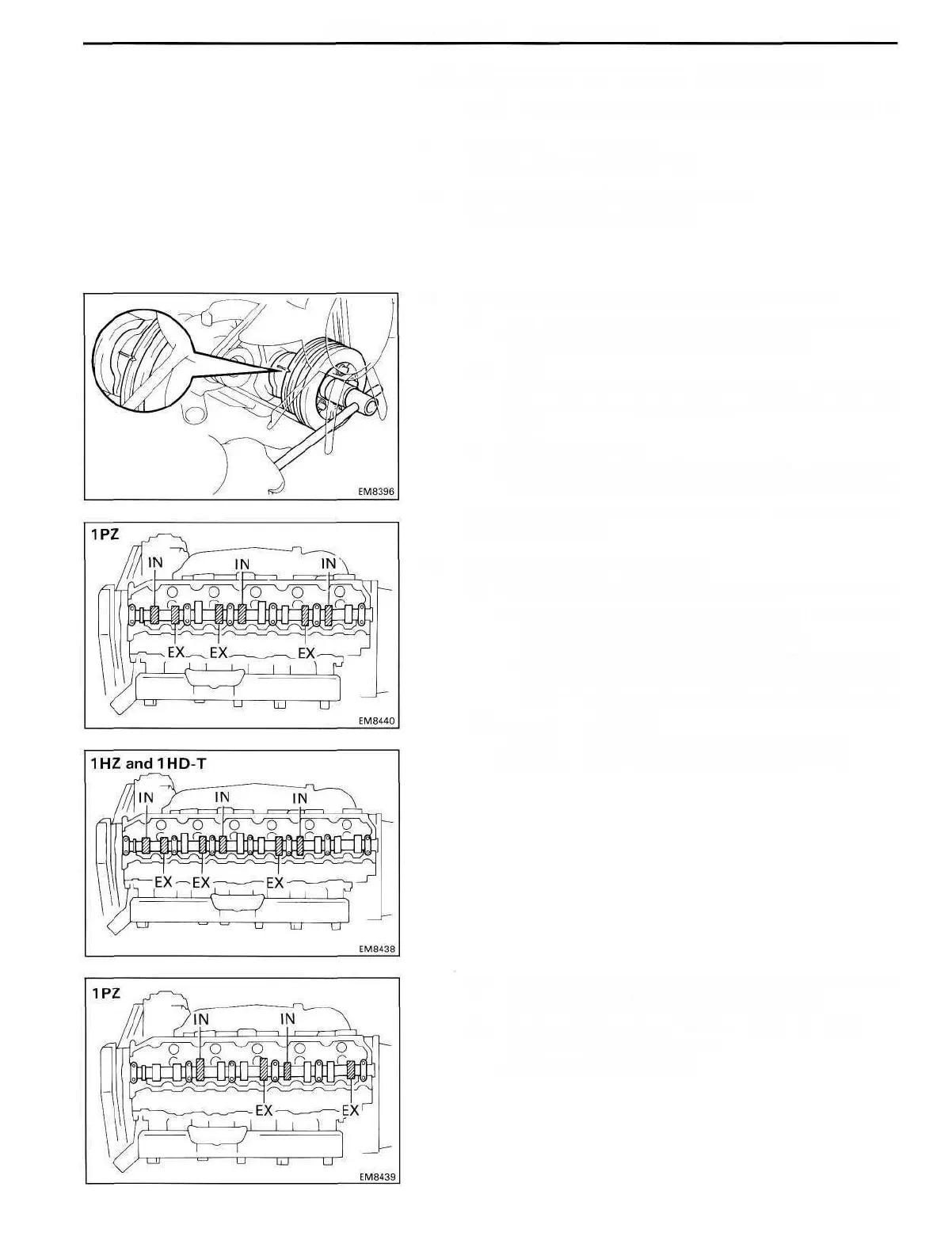

(b) (1PZ)

Check that the valve lifters on the No.1 cylinder are

loose and exhaust valve lifter on the No.5 cylinder is

tight.

(c) (1 HZ and 1HD-T)

Check that the valve lifters on the No.1 cylinder are

loose and valve lifters on the No.6 cylinder are tight.

If not, turn the crankshaft one revolution (360°) and align

the mark as above.

4. ADJUST VALVE CLEARANCE

(a) Check only those valves indicated in the illustration.

• Using a thickness gauge, measure the clearance

between the valve lifter and camshaft.

• Record the valve clearance measurements which

are out of specification. They will be used later to

determine the required replacement adjusting shim.

Valve clearance (Cold):

Intake 0.15-0.25 mm (0.006-0.010 in.)

Exhaust 0.35-0.45 mm (0.014-0.018 in.)

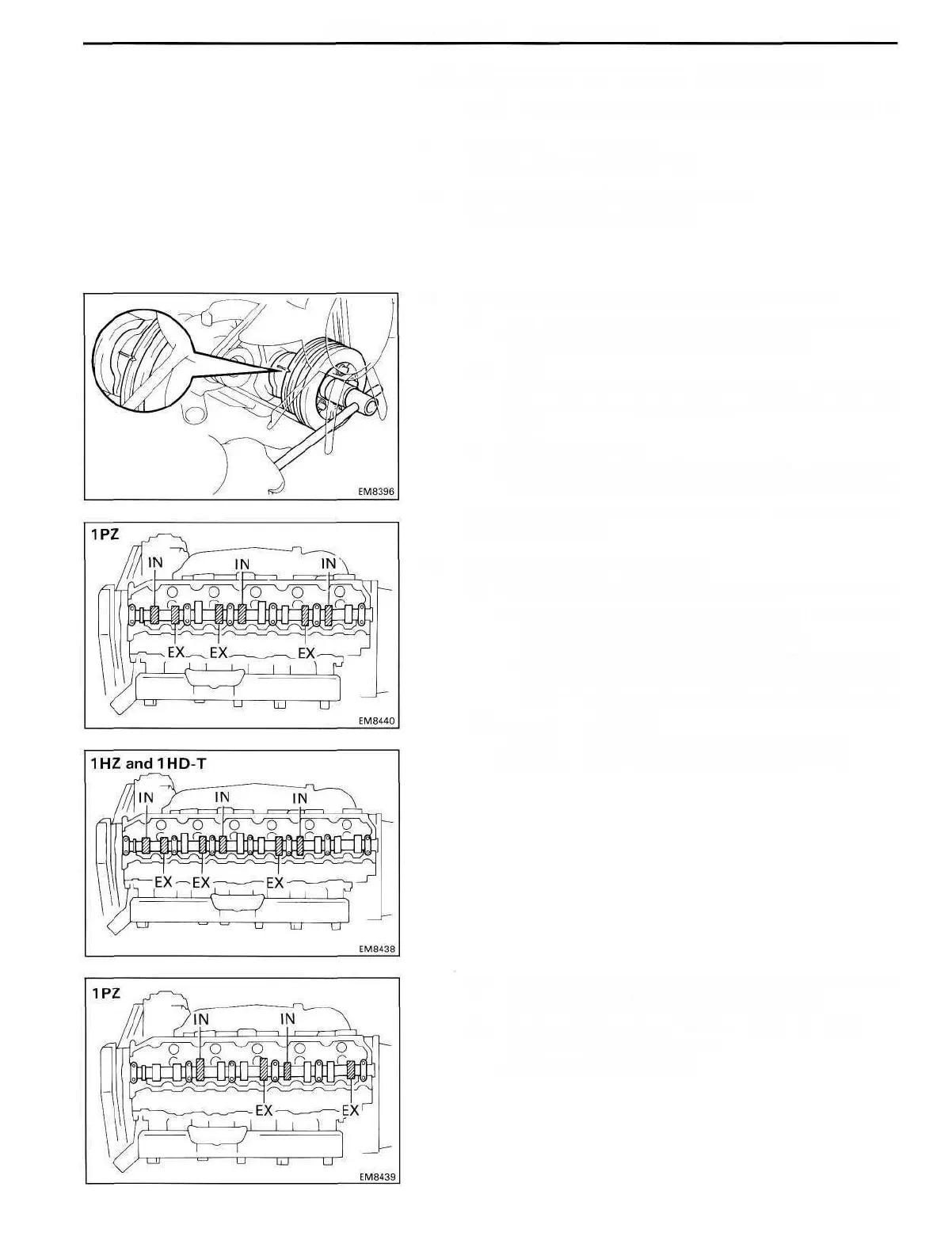

(b) Turn the crankshaft one revolution (360°), and align

the mark as above (See procedure step 3).

(c) Check only the valves indicated in the illustration.

Measure the valve clearance.

(See procedure step (a))

Loading...

Loading...