P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

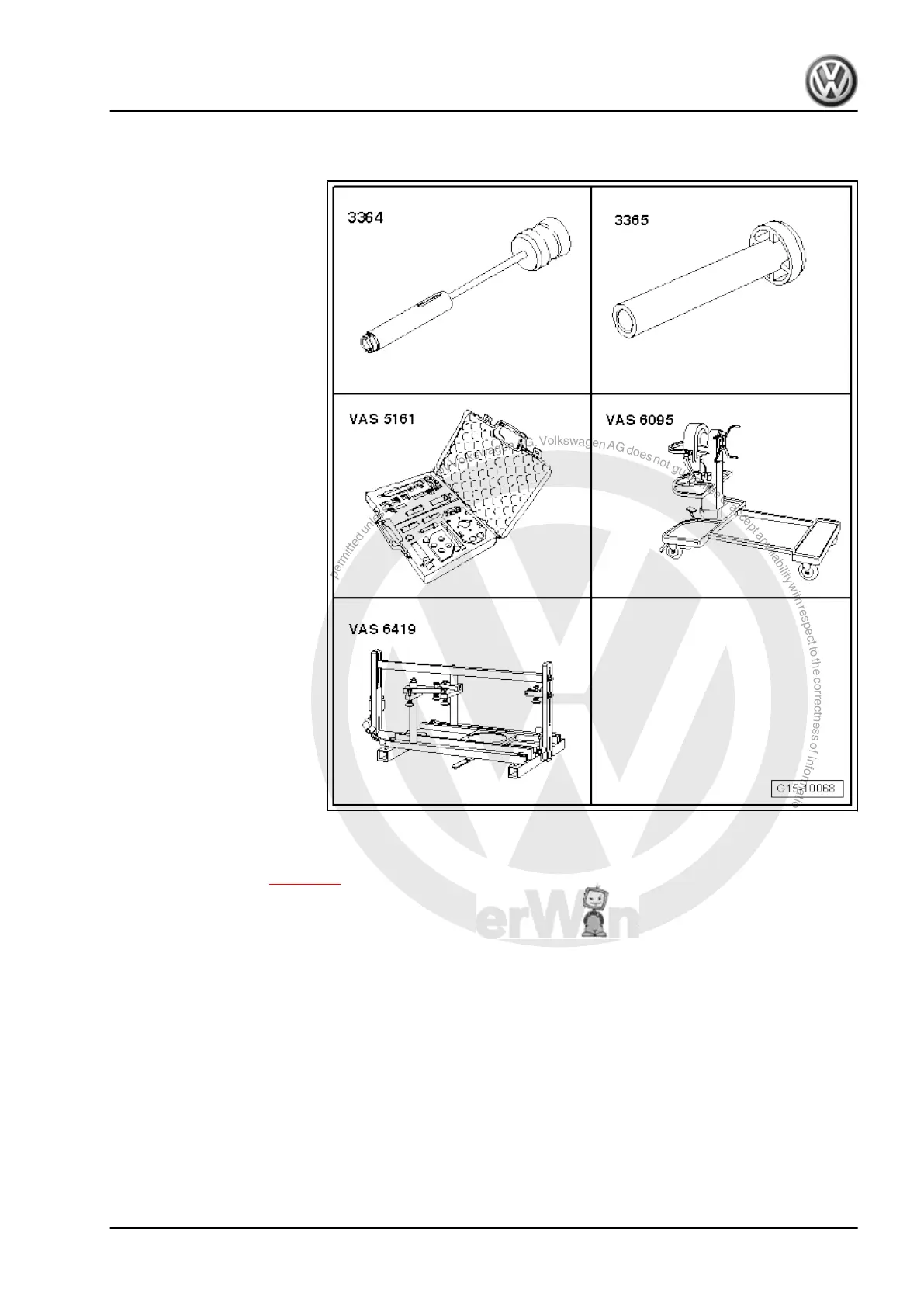

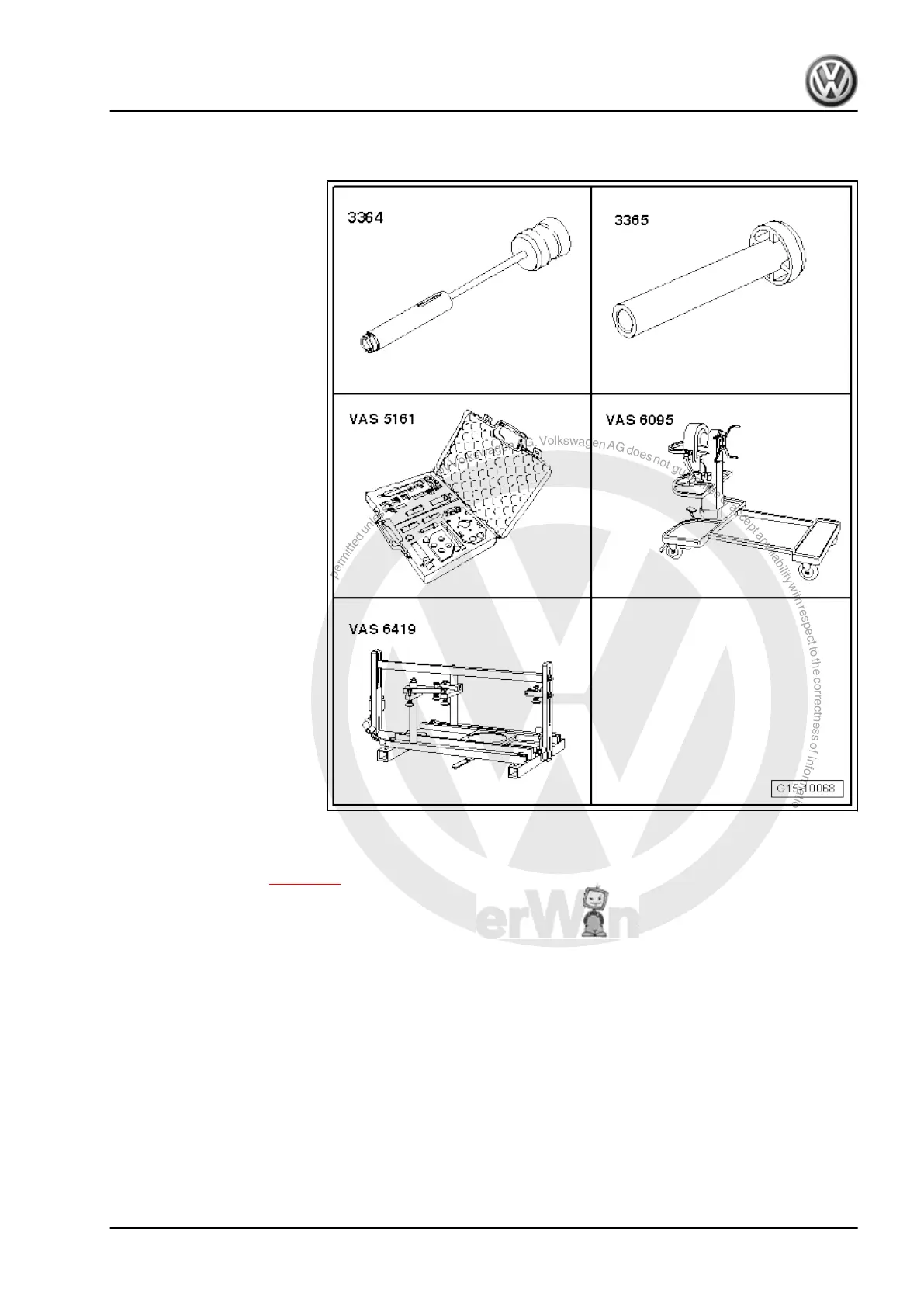

3.4 Renewing valve stem seals with cylinder head removed

Special tools and workshop

equipment required

♦ Valve stem seal puller

-3364-

♦ Valve stem seal fitting tool

-3365-

♦ Dismantling and assem‐

bling device for valve cot‐

ters -VAS 5161-

♦ Guide plate for 2.0 l and 3.0

l FSI engine -VAS

5161/19B-

♦ Engine and gearbox sup‐

port -VAS 6095-

♦ Cylinder head tensioning

device -VAS 6419-

Procedure

– Remove camshafts ⇒ page 94 .

– Mark allocation of roller rocker fingers and hydraulic compen‐

sation elements for reinstallation.

– Remove roller rocker fingers together with hydraulic compen‐

sation elements and place down on a clean surface.

– Insert cylinder head tensioning device -VAS 6419- into engine

and gearbox support -VAS 6095- .

– Tension cylinder head on cylinder head tensioning device as

shown in illustration.

– Connect cylinder head tensioning device to compressed air.

Amarok 2011 ➤

4-cylinder injection engine (2.0 l direct injection engine, turbocharger) - Edition 02.2011

3. Valve gear 109

Loading...

Loading...