P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

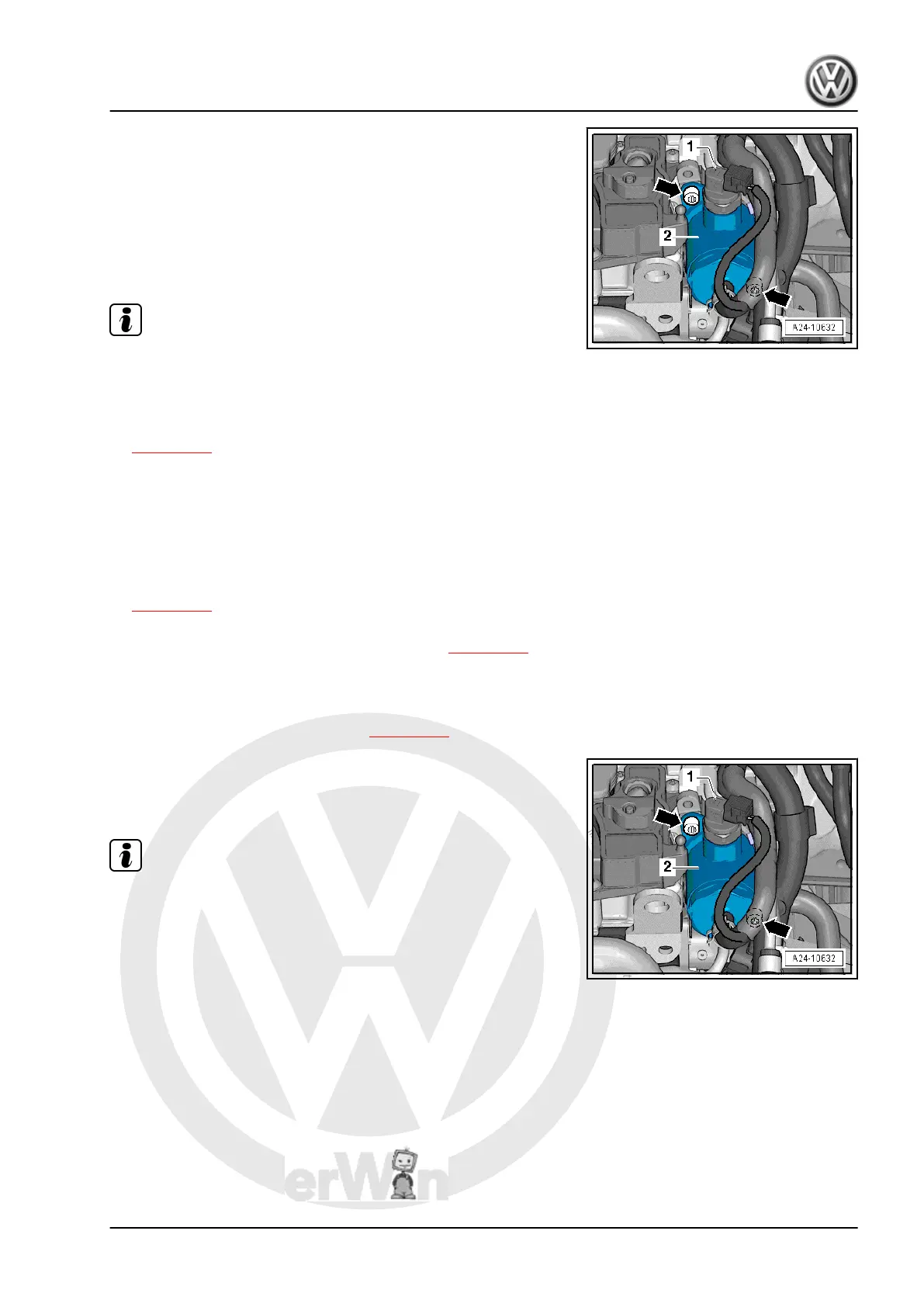

– Remove 2 bolts -arrows-.

– Carefully pull out high-pressure fuel pump. Sleeve can remain

inserted in vacuum pump.

Installing

– Renew high-pressure pump O-ring.

– Insert roller tappet in vacuum pump (first check roller tappet

for damage).

Note

♦

Roller tappet must be at bottom dead centre to enable high-

pressure pump to be installed.

♦

If same or a used high-pressure pump is installed, connection

for fuel pressurisation line (high-pressure side) must be re‐

newed. See assembly overview - high-pressure pump item 11

⇒ page 225

– Turn crankshaft until roller tappet is at bottom dead centre.

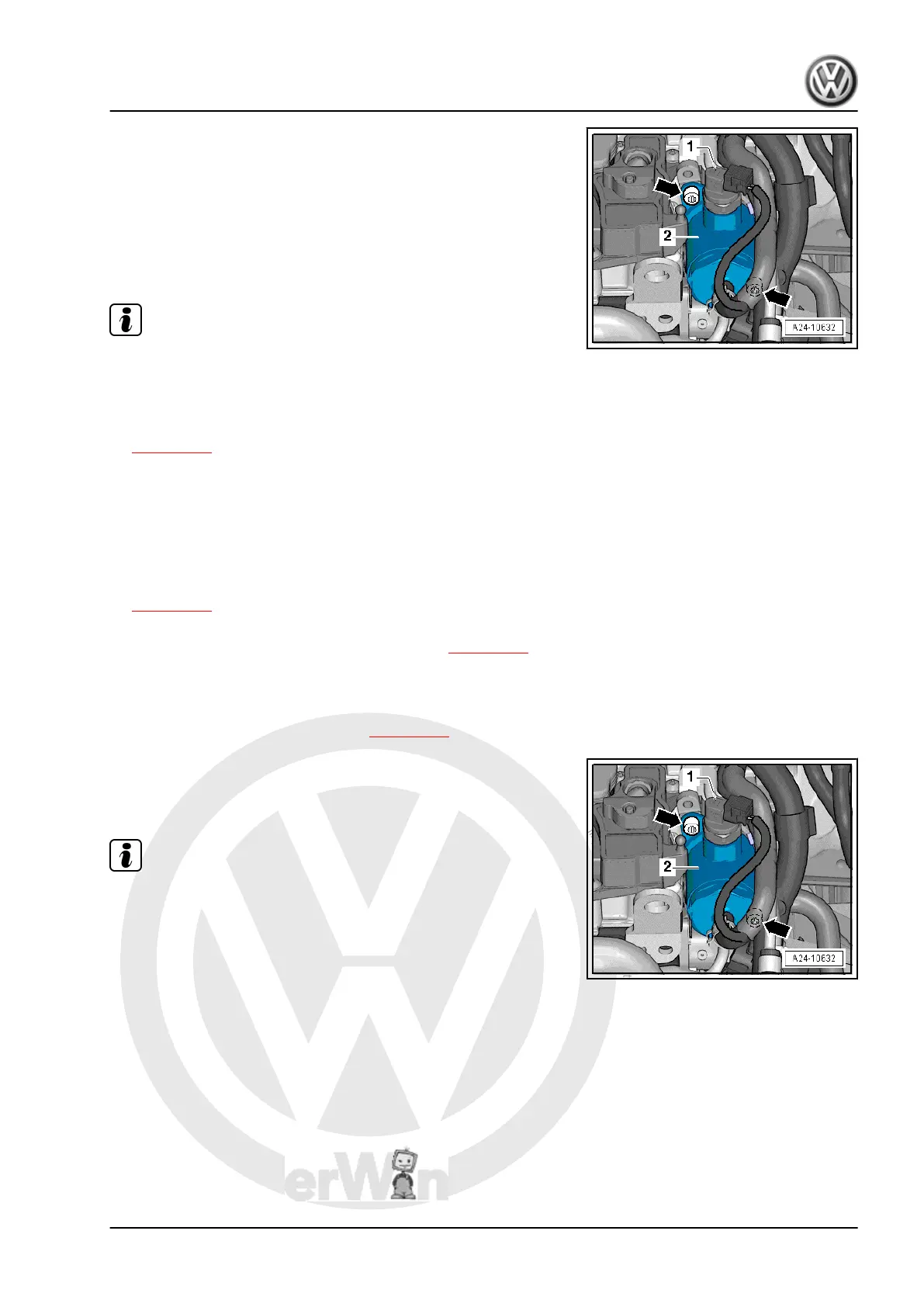

– Insert high-pressure pump into vacuum pump and tighten.

– Tighten bolts hand tight.

– Renew high-pressure pump connection.

• Specified torque: assembly overview - high-pressure pump

⇒ page 225 .

– Now tighten bolts in diagonal sequence to specified torque,

see assembly overview - high-pressure pump ⇒ page 225 .

– Tighten union nut of high-pressure line hand-tight. Align free

of tension.

• Specified torque for fuel pressurisation line (union nut): as‐

sembly overview - intake manifold ⇒ page 213 .

– Reattach connector to fuel pressure regulating valve -N276-

-1-.

– Put back fuse if it has been removed.

Note

Check fuel system for leaks.

2.17 Removing and installing engine control

unit

Special tools and workshop equipment required

Amarok 2011 ➤

4-cylinder injection engine (2.0 l direct injection engine, turbocharger) - Edition 02.2011

2. Injection system 227

Loading...

Loading...