P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Note

♦

The injector must insert easily. If necessary, wait until the

combustion chamber seal has contracted sufficiently.

♦

Ensure the injectors are correctly seated and positioned in the

cylinder head.

♦

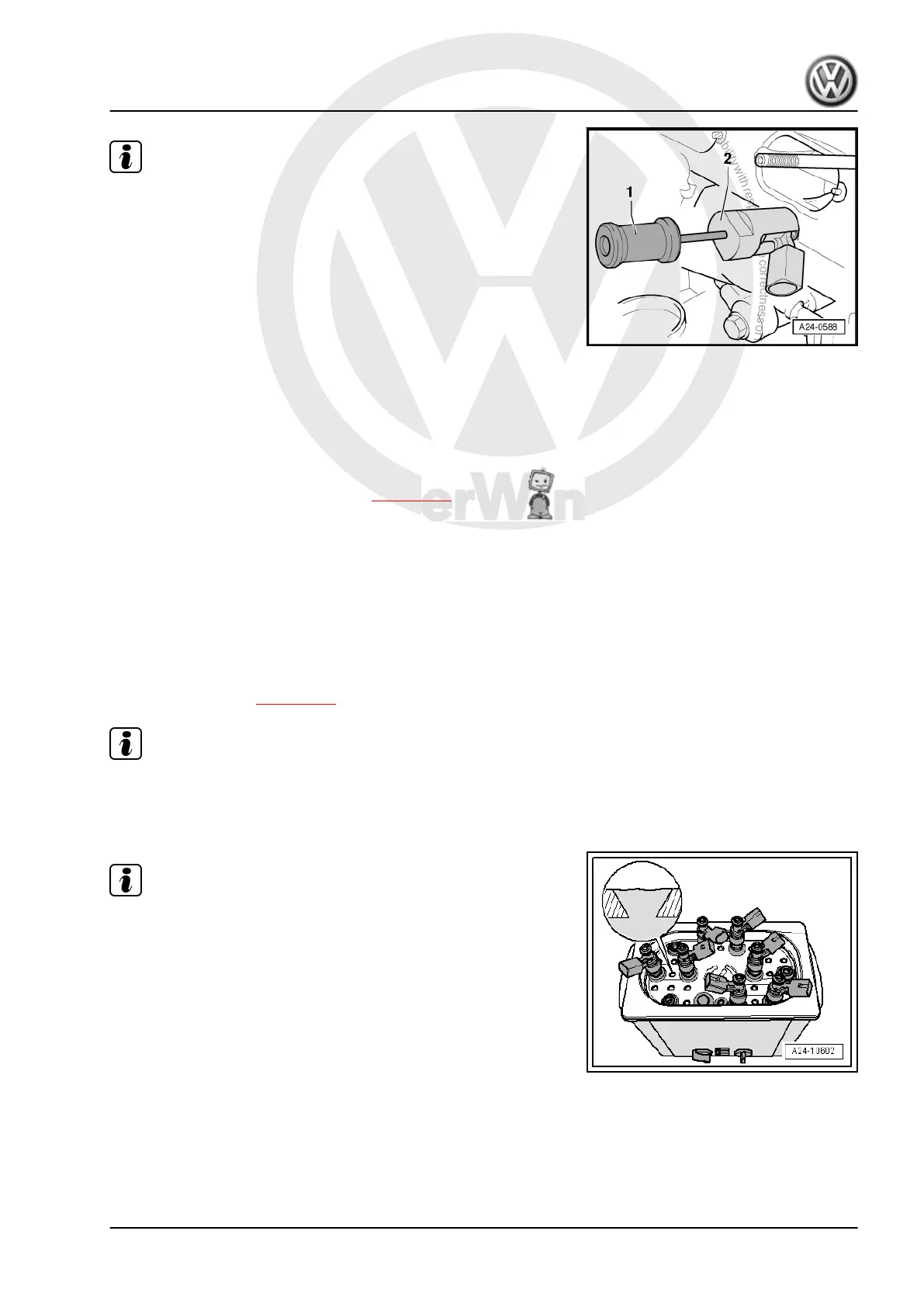

If it is not possible to insert the injector by hand, use the puller

-T10133/2A- -2- with a hammer -T10133/3- to insert the injec‐

tor.

– Install analogously in reverse order.

Important: It is essential to observe following points

• Moisten O-rings of high-pressure injectors with clean engine

oil to aid insertion into fuel rail.

• Renew all gaskets.

• Fuel rail must be placed on injectors and evenly pressed in.

• Install intake manifold with fuel rail ⇒ page 211 .

2.11 Cleaning injectors

Special tools and workshop equipment required

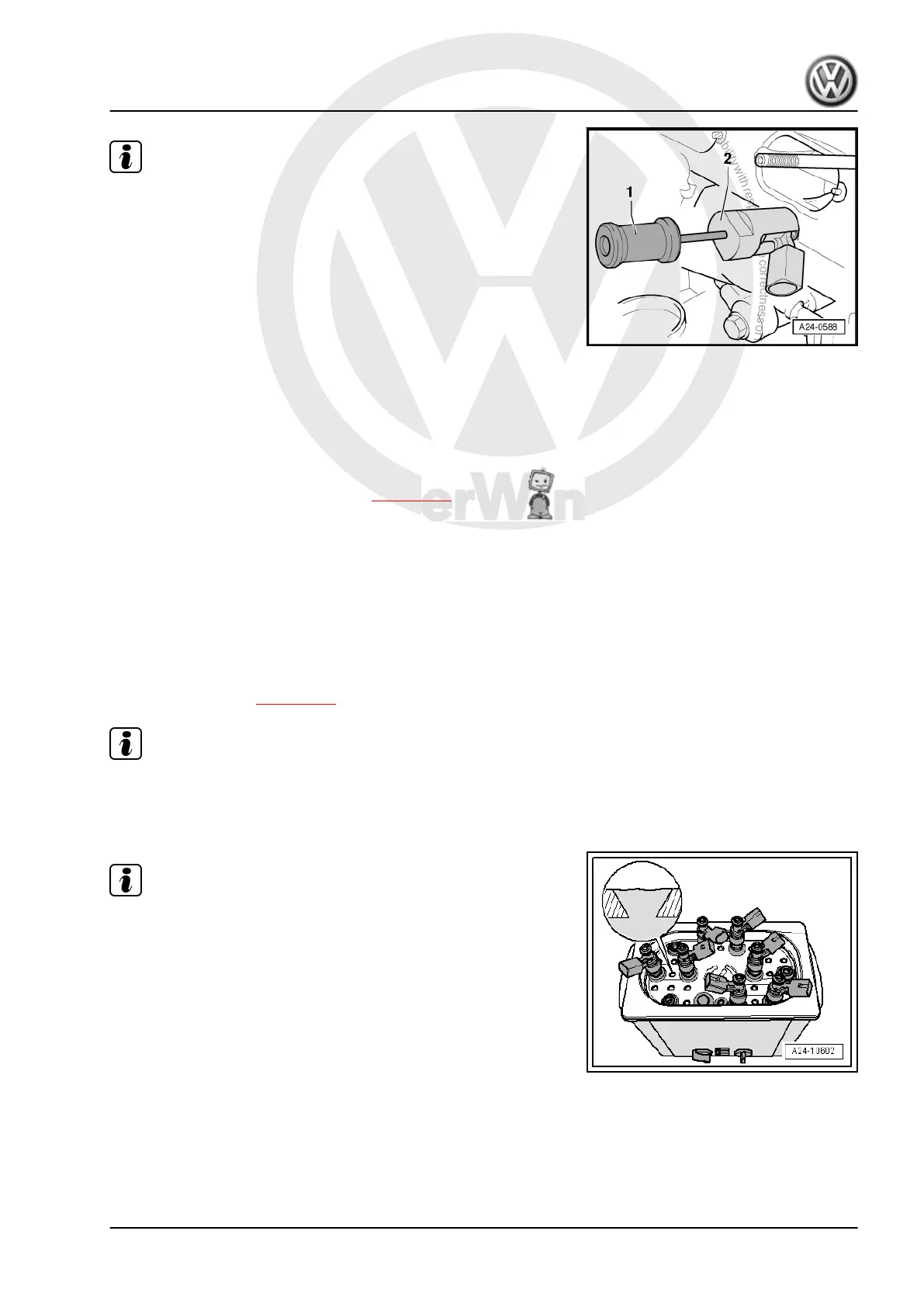

♦ Ultrasonic cleaner -VAS 6418-

♦ Mounting plate for injection modules -VAS 6418/1-

♦ Cleaning fluid -VAS 6418/2-

Cleaning

– Remove injectors ⇒ page 217 .

Note

Observe ultrasonic unit safety regulations and operating instruc‐

tions.

– Ultrasonic unit must be filled with cleaning fluid -VAS 6418/2- .

Note

Ultrasonic unit must be filled with cleaning agent up to upper edge

of holes (see expanded view).

– Insert injectors-1- into mounting plate for injection modules -

VAS 6418/1- as far as stop -2-.

Amarok 2011 ➤

4-cylinder injection engine (2.0 l direct injection engine, turbocharger) - Edition 02.2011

2. Injection system 221

Loading...

Loading...