P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

– Remove main bearing caps and clean bearing caps and jour‐

nals.

– Place a length of Plastigage corresponding to the width of the

bearing on the bearing journal or in the bearing shells.

• Plastigage must rest in middle of bearing shell.

– Fit main bearing caps and tighten to 60 Nm without rotating

crankshaft.

– Remove main bearing cap again.

– Compare width of Plastigage with the measurement scale.

Radial clearance:

• New: 0.017 … 0.037 mm.

• Wear limit: 0.15 mm

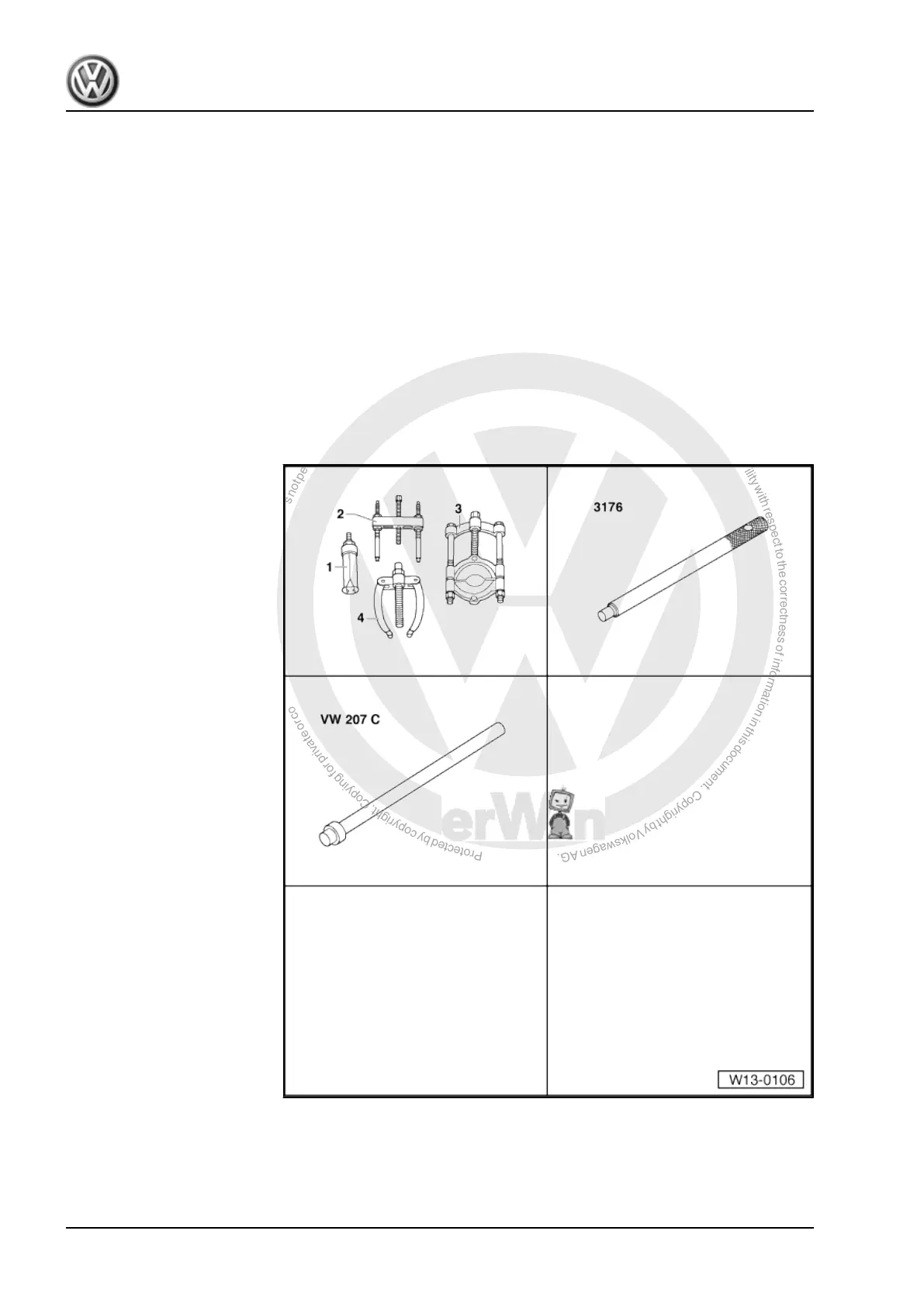

4.6 Pulling needle bearing out of and driving into crankshaft

Special tools and workshop

equipment required

♦ Internal puller -Kukko 21/2-

and internal puller -Kukko

22/1-

♦ Centring mandrel -3176-

♦ Drift -VW 207 C-

Removing

Procedure

• Gearbox is separated from engine.

Amarok 2011 ➤

4-cylinder injection engine (2.0 l direct injection engine, turbocharger) - Edition 02.2011

44 Rep. gr.13 - Crankshaft group

Loading...

Loading...