P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

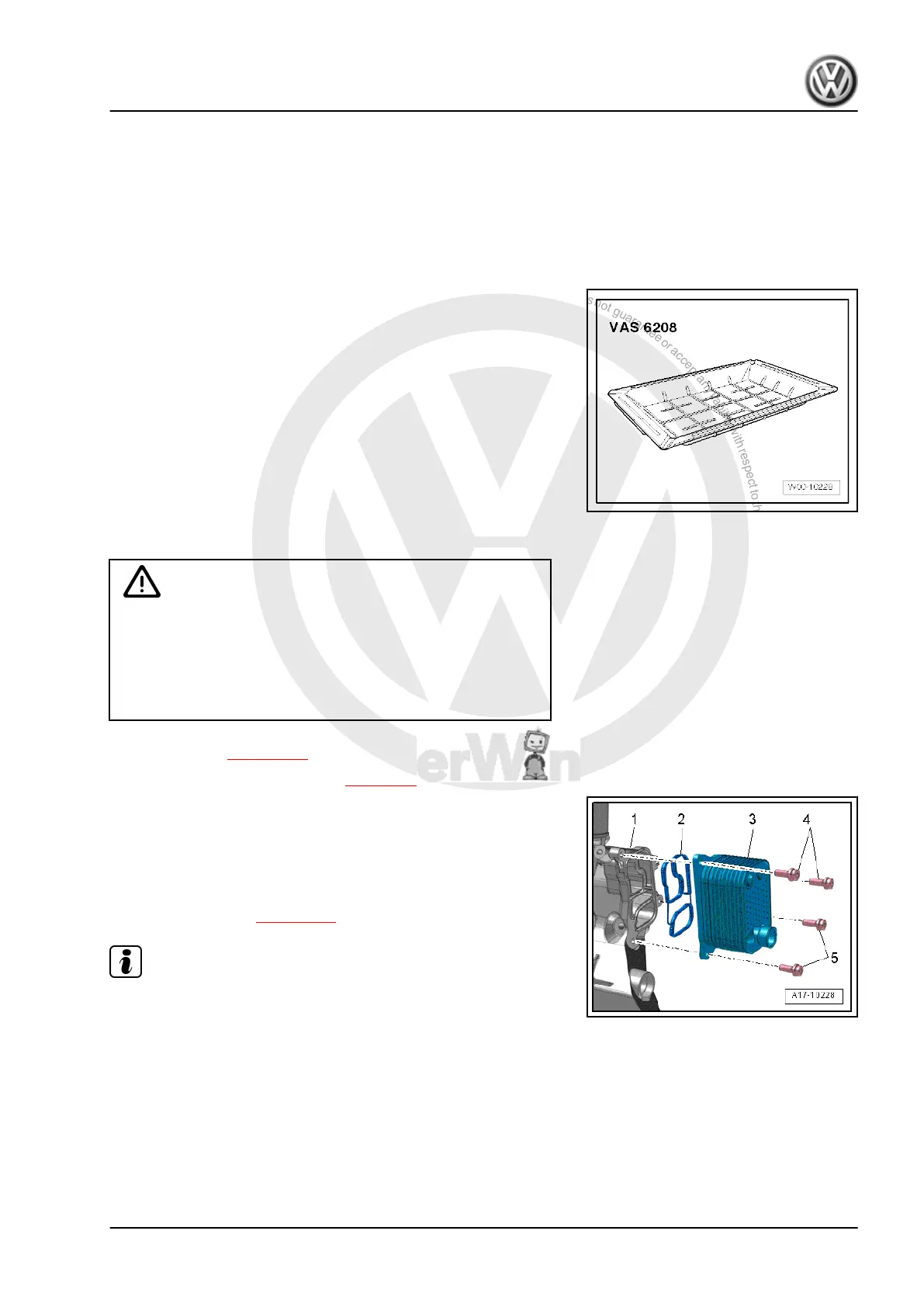

14 - Bolt

❑ Tightening sequence

2.2 Removing and installing engine oil cool‐

er

Special tools and workshop equipment required

♦ Drip tray for workshop hoist -VAS 6208-

Removing

WARNING

Hot steam/hot coolant can escape - risk of scalding.

♦ The cooling system is under pressure when the engine is

hot.

♦ Cover filler cap on expansion tank with a cloth and open

carefully to dissipate pressure.

– Drain coolant ⇒ page 133 .

– Remove bracket for ancillaries ⇒ page 24 .

– Unscrew bolts -4 and 5- and remove engine oil cooler -3- to‐

gether with seal -2-.

Installing

Installation is carried out in the reverse order. When installing,

note the following:

• Specified torques ⇒ page 128 .

Note

♦

Renew gaskets and seals.

♦

Secure all hose connections with hose clips corresponding to

the series equipment ⇒ Electronic parts catalogue .

Amarok 2011 ➤

4-cylinder injection engine (2.0 l direct injection engine, turbocharger) - Edition 02.2011

2. Oil filter bracket, oil pressure, engine oil cooler and oil supply line 129

Loading...

Loading...