P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

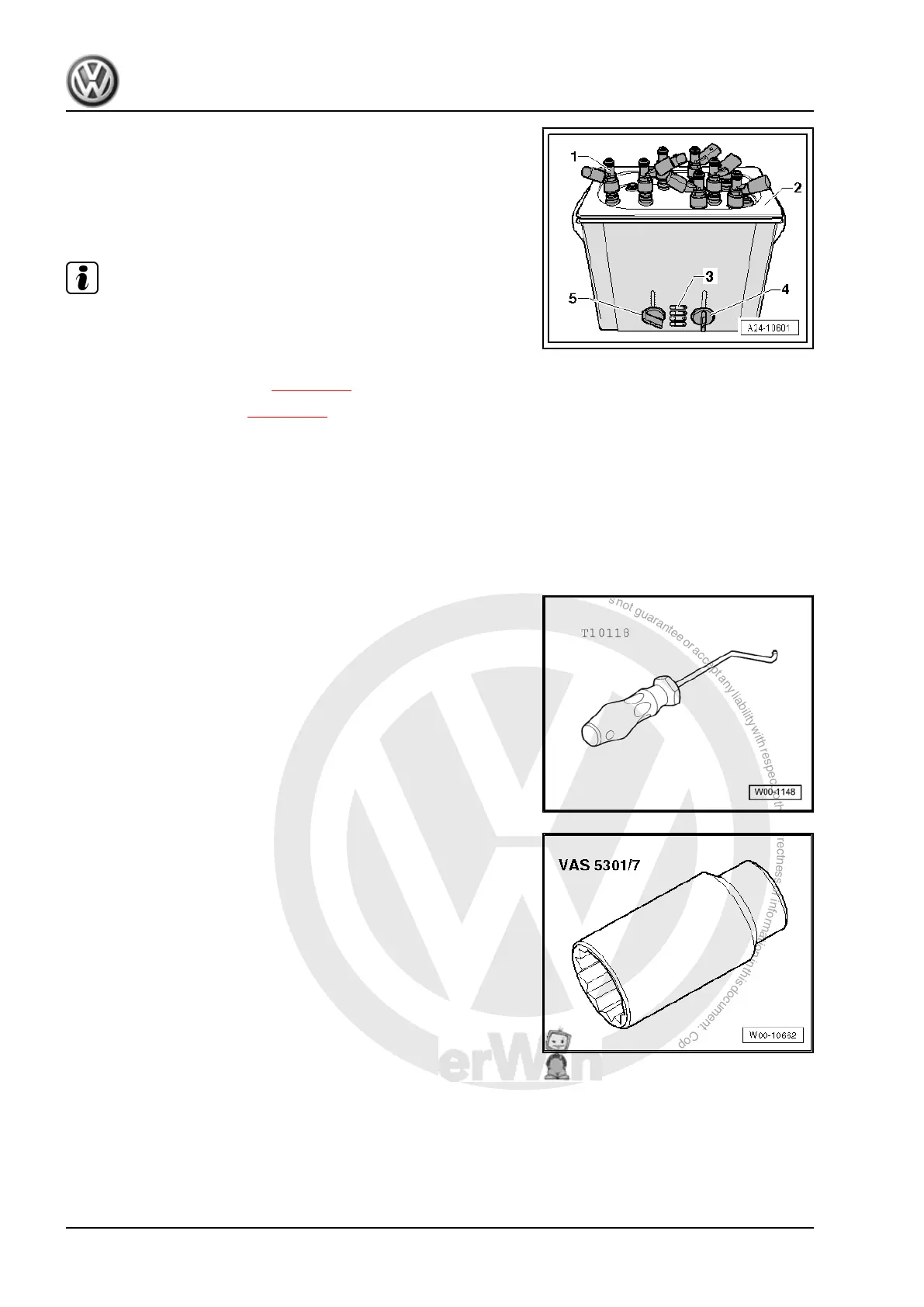

– Dip injectors together with mounting plate for injection mod‐

ules -VAS 6418/1- into cleaning fluid.

– Set a temperature of 50 degrees with rotary knob -4-.

– Set rotary knob -5- to a cleaning time of 30 minutes.

– Press button -3- to switch ultrasonic unit on.

Note

As soon as the cleaning temperature is 50 degrees, the set time

will begin to elapse.

– Each time after cleaning injector, renew combustion chamber

ring seal (Teflon ring seal) ⇒ page 219 .

– Then reinstall injectors ⇒ page 217 .

2.12 Removing and installing fuel pressure

sender -G247-

If fuel pressure sender -G247- fails, fuel pressure regulating valve

-N276- is switched off, electric fuel pump is is fully actuated, and

engine is operated with available fuel pressure. Engine torque is

drastically reduced as a result.

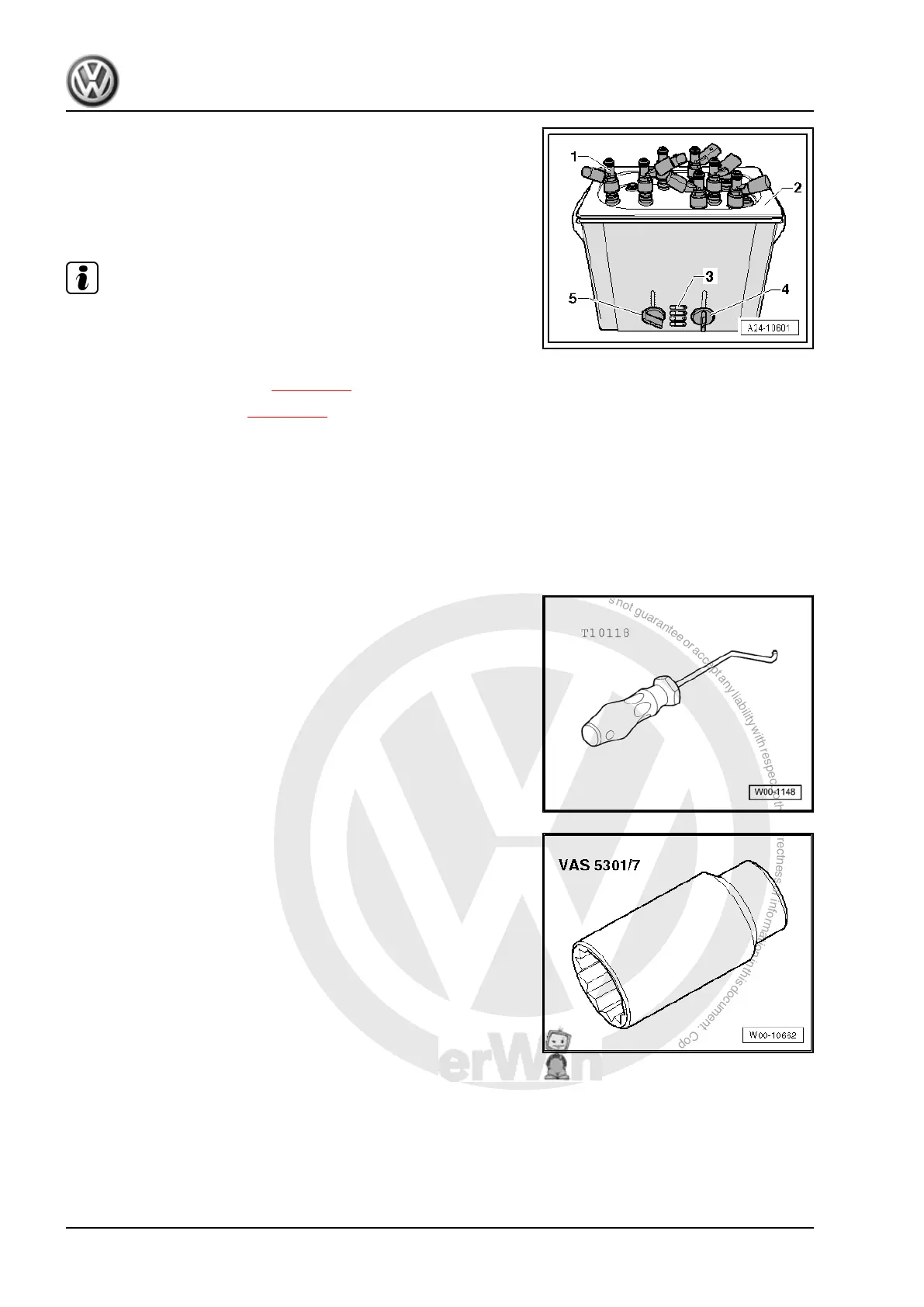

Special tools and workshop equipment required

♦ Assembly tool -T10118-

♦ Double hexagon socket, 1/2, 27mm -VAS 5301/7- or commer‐

cially available 27 mm socket

Amarok 2011 ➤

4-cylinder injection engine (2.0 l direct injection engine, turbocharger) - Edition 02.2011

222 Rep. gr.24 - Mixture preparation - injection

Loading...

Loading...