APPENDIX B : COMPRESSOR DRIVEN AIRDRYER

B--20 20950 Issue 1 April 98

FAULT FINDING AND REPAIR

TheairdryerPCBcontainsaswitch andlinkswhichshouldbesetason

Pg. B--31, see also service diagrams on Pg. B--41.

Fault Diagnosis

The following tables are provided for help in fault finding.

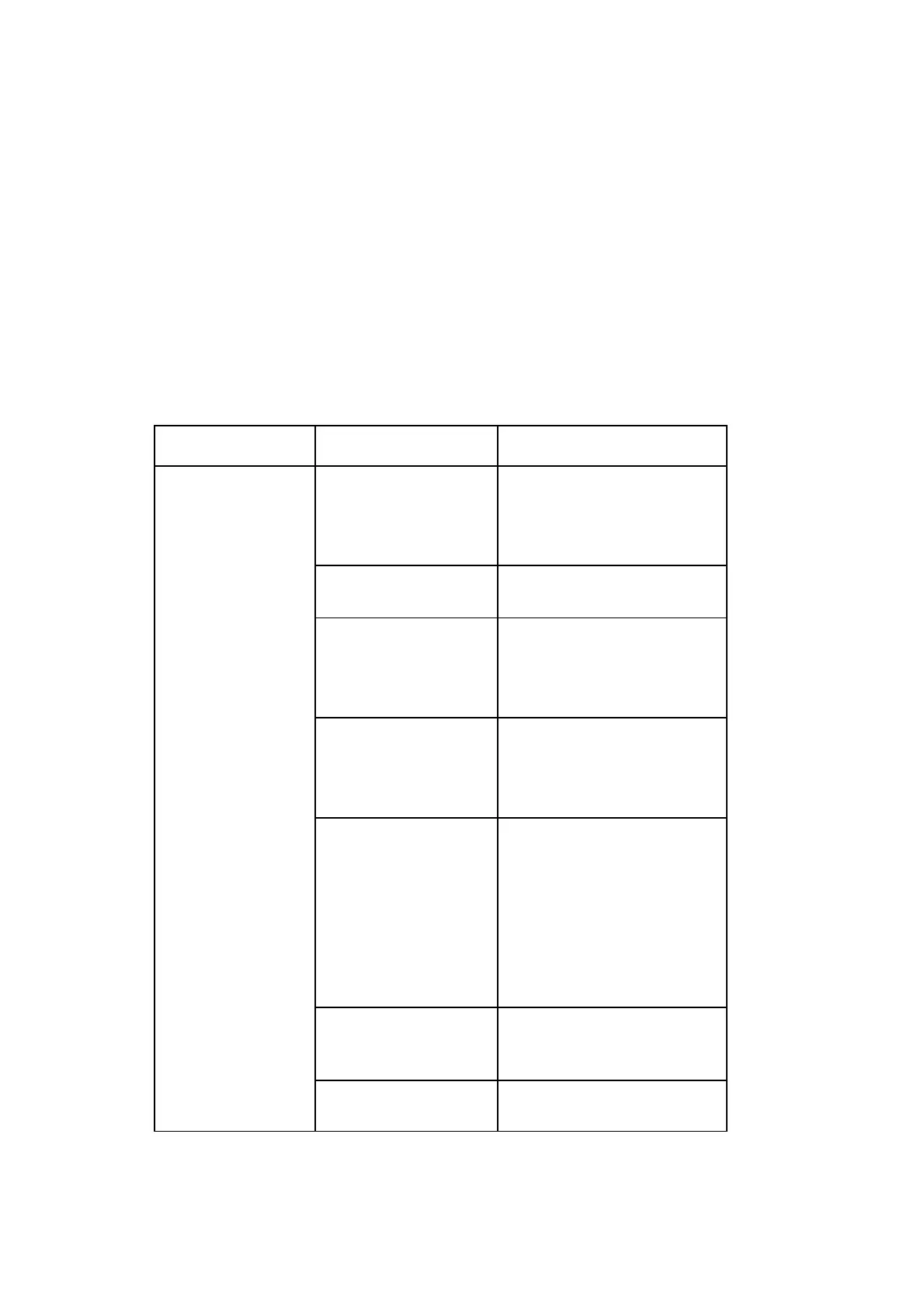

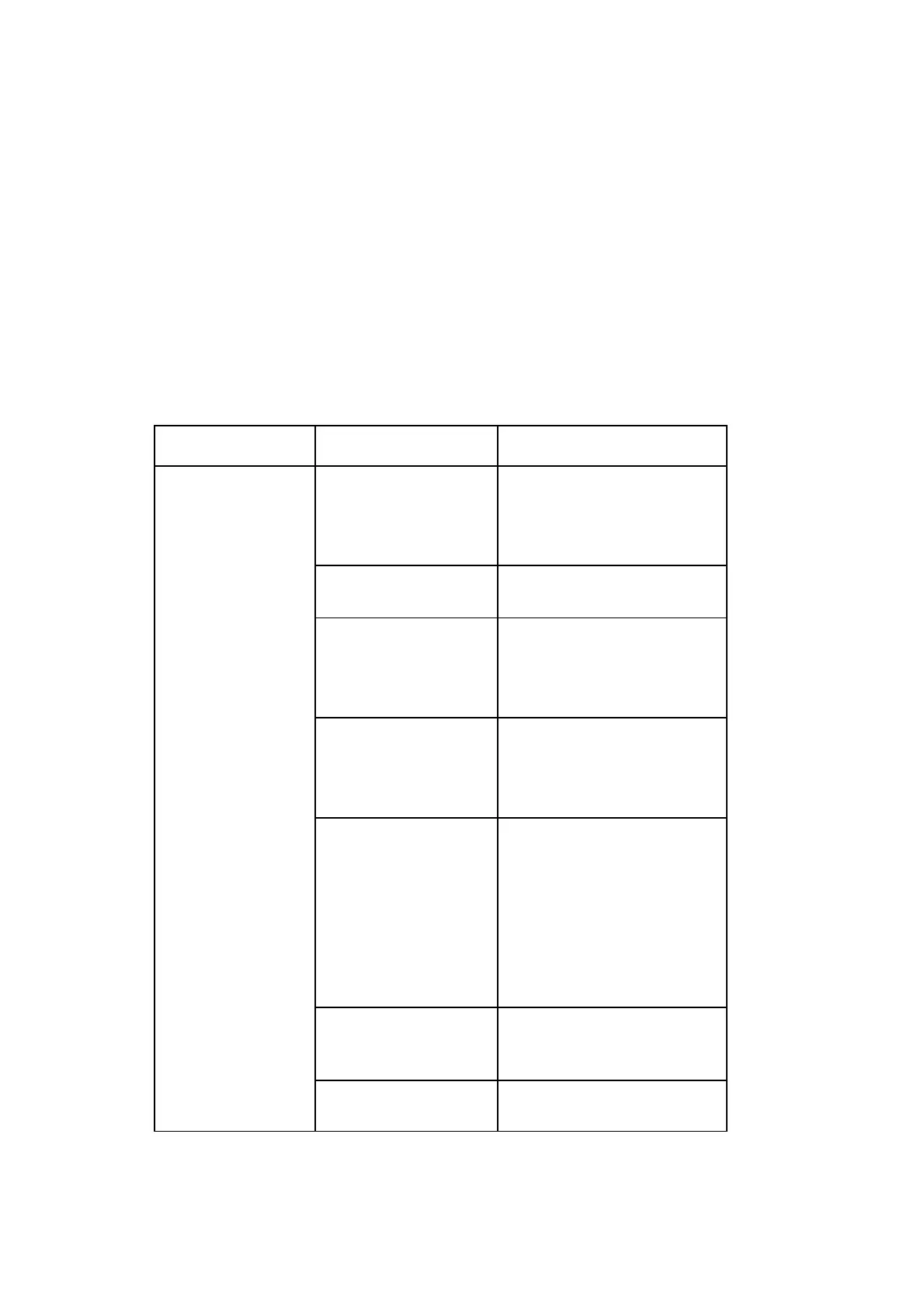

Air Pressure Faults

FAULT POSSIBLE CAUSE ACTION

No flow at print

head.

Kink or loose

connection in tubes

connecting airdryer

to printer.

Check air flow from

dryer.

Check tubes and

connections.

Needle valve closed

or blocked.

Clean and/or adjust

needle valve.

Filter blocked. Check filter between

Peltier assembly and

regulator.

Check compressor filter.

Compressor faulty. Check for electrical

supply failure.

Check for mechanical

failure.

Solenoid valve

permanently open

or leaking.

Check solenoid valve.

Check solenoid valve

wiring.

Check solenoid control

from PCB -- set LK2 to

position 1--2 and check

operation every 6 secs.

Reset to position 3--4.

Air leak in system. Check for split tubes,

broken or loose

connections.

PRV permanently

open.

Clean or replace PRV.

Loading...

Loading...