Rosemount Model 1195/ProPlate/Mass ProPlate

9-2

REMOVE THE

FLOWMETER

FROM SERVICE

NOTE

Once you have determined a that flowmeter is inoperable, remove it

from service.

Be aware of the following:

• Isolate and vent the process from the flowmeter before removing

the flowmeter from service.

• Remove all electrical leads and conduit.

• Do not detach the process flange or the electronics without

consulting the factory.

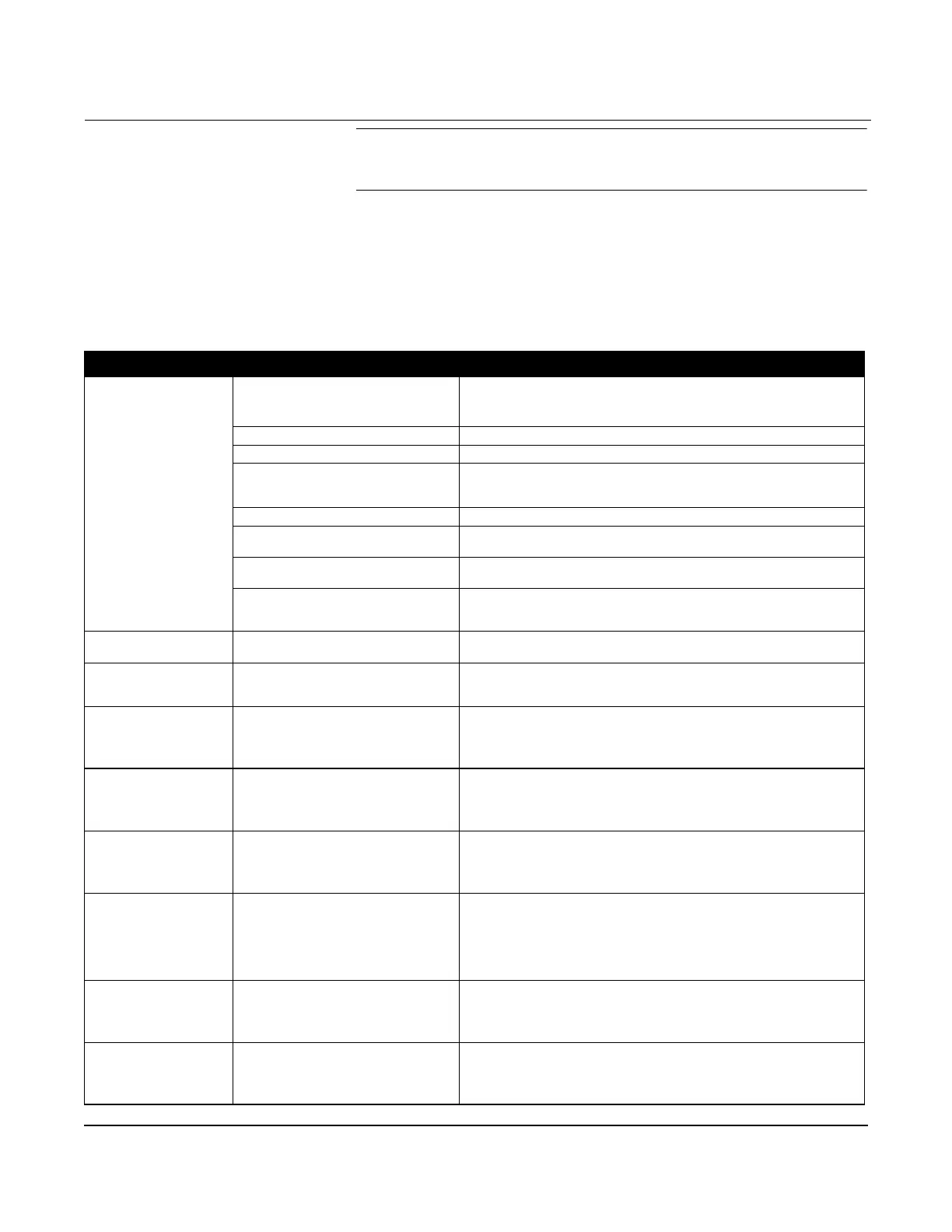

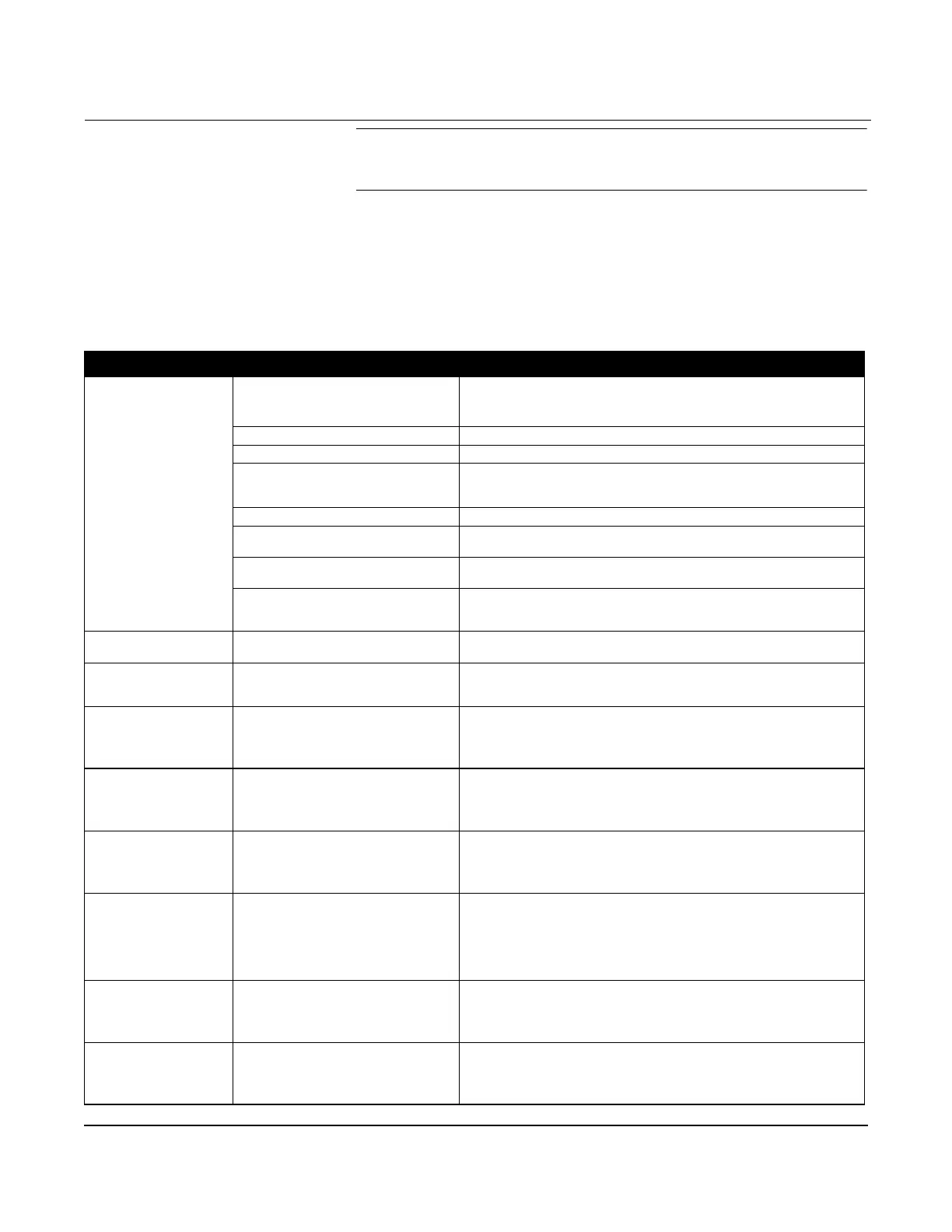

Symptom Possible Cause Corrective Action

Questionable accuracy or

erroneous flow signal

Improper installation

• Is the ProPlate flow arrow pointed in the direction of the flow?

• Verify that the cross reservoirs are perfectly level with one another.

• Is there sufficient straight run upstream and downstream of the ProPlate?

System leaks Check for leaks in instrument piping. Repair and seal all leaks.

Contamination/plugging Remove the ProPlate and check for contamination.

Closed valve Verify that both ProPlate (PH & PL) or (MH & ML) valves are open. Verify that

vent, equalizer, and line valves are properly positioned per the “start up

procedure.”

ProPlate calibration

Is the ProPlate calibration too high or low for the flow rate?

ProPlate connections (remote mount only) Verify that the high side of the ProPlate electronics is connected to the high side

of the ProPlate. Check the same for the low side.

Entrapped air (liquid applications) Are there uneven water legs caused by air entrapment in the instrument

connections? If so, bleed air.

Operating conditions Are the operating conditions in compliance with those given at the time the

flowmeter was purchased? Check the flow calc and the fluid parameters for

accuracy. Double-check pipe inside diameter for proper ProPlate sizing.

Spiking flow signal Two-phase flow The ProPlate is a head measurement device and will not accurately measure a

two-phase flow.

Spiking flow signal (Stream

Service)

Improper insulation (Vertical pipes only)

Excessive vibration

Added insulation may be required to ensure that a phase change occurs at the

cross reservoirs.

Check the impulse piping for vibration.

Milliamp reading is zero

• Check if power polarity is reversed

• Verify voltage across terminals (should be 10–55V dc)

• Check for bad diode in terminal block

• Replace electronics terminal block

ProPlate electronics not in

communication

• Check power supply voltage at electronics (10.5V minimum)

• Check load resistance (250 ohms minimum)

• Check if unit is addressed properly

• Replace electronics board

Milliamp reading is low or

high

• Check pressure variable reading for saturation

• Check if output is in alarm condition

• Perform 4–20 mA output trim

• Replace electronics board

No response to changes in

applied flow

• Check test equipment

• Check impulse piping for blockage

• Check for disabled span adjustment

• Check electronics security jumper

• Verify calibration settings (4 and 20 mA points)

• Contact factory for replacement

Low reading/high reading

• Check impulse piping for blockage

• Check test equipment

• Perform full sensor trim (if software revision is 35 or higher)

• Contact factory for replacement

Erratic reading for pressure

variable

• Check impulse piping for blockage

• Check damping

• Check for EMF interference

• Contact factory for replacement

Loading...

Loading...