Rosemount Model 1195/ProPlate/Mass ProPlate

3-2

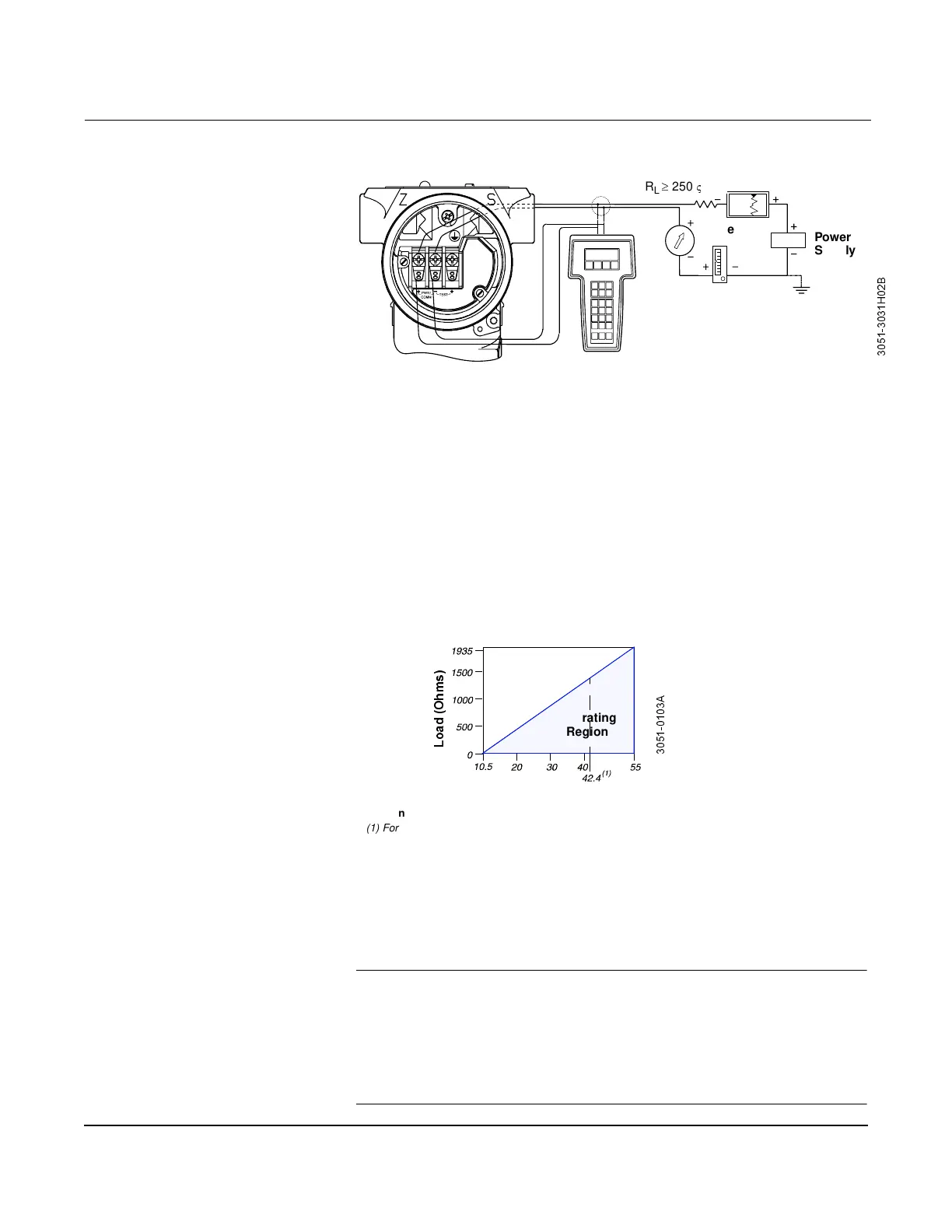

Figure 3-1. Field Hook-up

(4–20 mA Flowmeters)

Electrical Considerations The signal terminals are located in a compartment of the electronics

housing separate from the ProPlate electronics. Connections for the

HART-based communicator are located below the signal terminals. The

Model 272 Field Calibrator can be connected at the signal terminals to

provide power to the electronics temporarily for calibration or

diagnostic purposes. Otherwise, the calibrator may be attached to the

test connections on the terminal block of the electronics for indication

purposes. Figure 3-2 illustrates power supply load limitations for the

ProPlate.

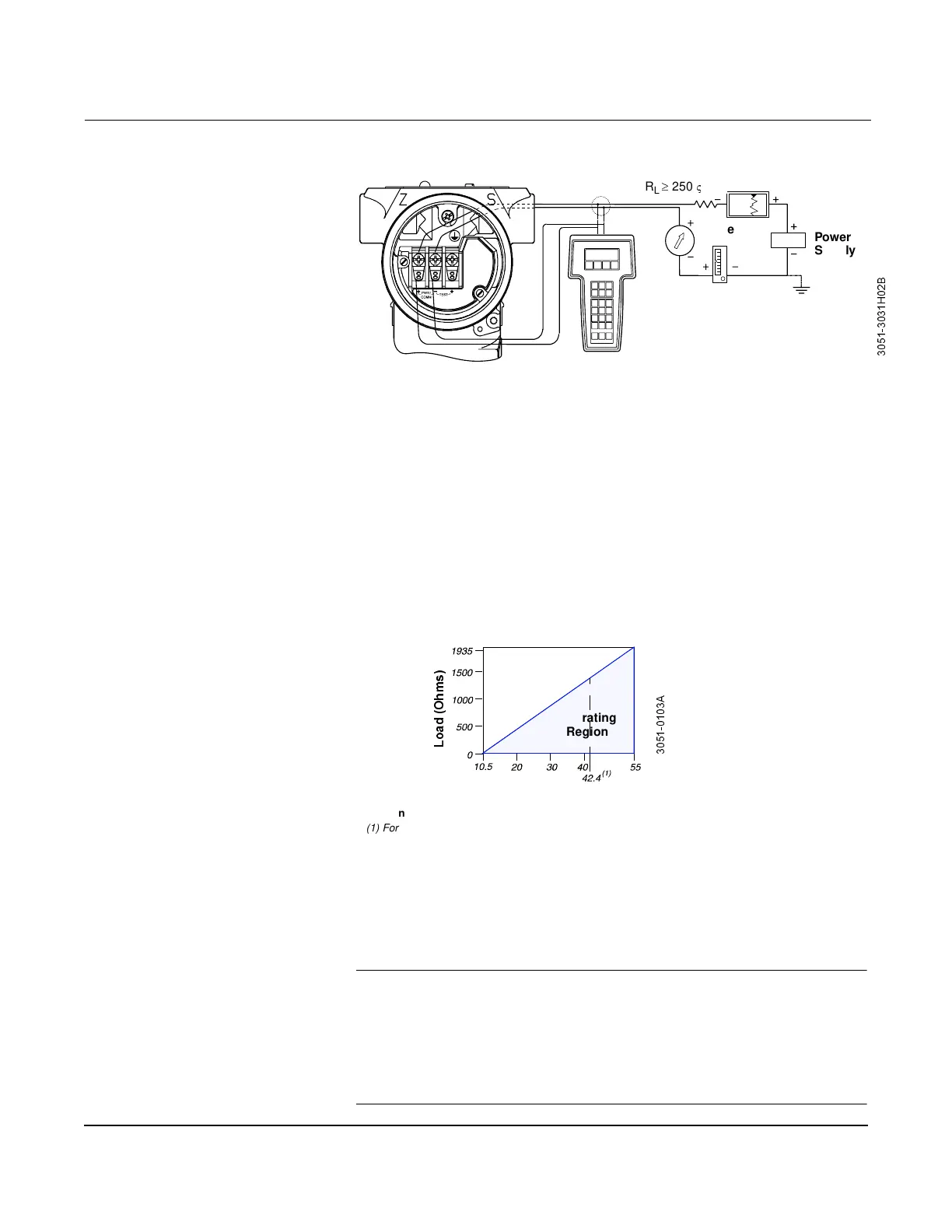

Figure 3-2. Power Supply Load

Limitations.

Power Supply (4–20mA

electronics)

The dc power supply should provide power with less than 2 percent

ripple. The total resistance load is the sum of the resistance of the

signal leads and the load resistance of the controller, indicator, and

related pieces. Note that the resistance of intrinsic safety barriers, if

used, must be included.

NOTE

A minimum loop resistance of 250 ohms is required to communicate with a

HART-based communicator. With 250 ohms of loop resistance, the ProPlate

will require a minimum of 15.5 volts to output 20 mA. If a single power

supply is used to power more than one ProPlate, the power supply used, and

circuitry common to the ProPlates, should not have more than 20 ohms of

impedance at 1200Hz.

CAUTION

Do not use inductive-based transient protectors.

Signal point may be grounded at any

point or left ungrounded.

+

%

R

L

250

V

Power

Supply

Curre

Communication requires a minimum loop resistance of 250 ohms.

/

R

D

G

2

K

P

V

$

Voltage (V dc)

Operating

Region

(1) For CSA approval, power supply must not exceed 42.4 V.

Loading...

Loading...