3-5

MASS PROPLATE

FLOWMETER

This section provides electrical considerations and ProPlate field

wiring instructions.

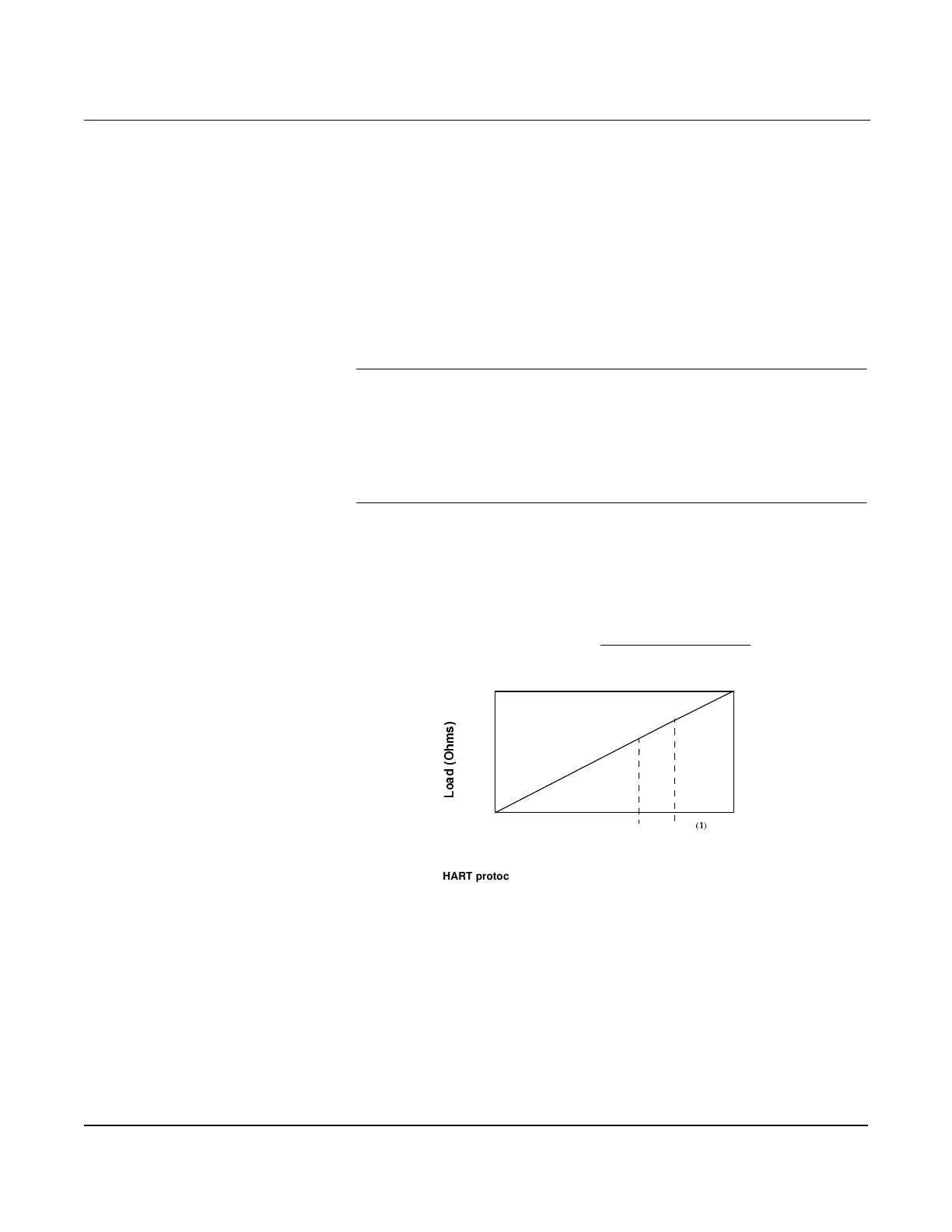

Electrical Considerations The signal terminals are located in a compartment of the electronics

housing separate from the electronics. Figure 3-3 illustrates power

supply load limitations for the Mass ProPlate.

Power Supply The dc power supply should provide power with less than 2% ripple.

The total resistance load is the sum of the resistance of the signal leads

and the load resistance of the controller, indicator, and related pieces.

Note that the resistance of intrinsic safety barriers, if used, must be

included.

NOTE

A loop resistance between 250-1100 ohms inclusive is required to

communicate with a personal computer. With 250 ohms of loop

resistance, a power supply voltage of at least 16.5 V dc is required.

(1)

If

a single power supply is used to power more than one Mass ProPlate,

the power supply used, and circuitry common to the Mass ProPlates,

should not have more than 20 ohms of impedance at 1200 Hz.

Figure 3-3. Mass ProPlate Power

Supply Load Limitations.

Load Limitations

Loop resistance is determined by the voltage level of the external power

supply, as described below:

HAZARDOUS LOCATIONS The Mass ProPlate has an explosion-proof housing and circuitry

suitable for intrinsically safe and non-incendive operation. Individual

Mass ProPlates are clearly marked with a tag indicating the

certifications they carry. See Section : Specifications and Reference

Data for specific approval categories.

(1) Quick troubleshooting check: There must be at least 11.0 V DC across the Mass Pro-

Plate electronics terminals.

2000

0

11.0

4–20 mA dc

55

/

R

D

G

2

K

P

V

HART protocol communication requires a loop resistance value

between 250–1100 ohms, inclusive.

Max. Loop Resistance = Power Supply Voltage–11.0

0.022

Power Supply Voltage V dc

35

(1) For CSA approval, power supply must not exceed 42.4 V dc.

Operating Region

42.4 V

(1)

Loading...

Loading...