Rosemount Model 1195/ProPlate/Mass ProPlate

10-2

Flange and Pipe Material (if applicable)

316L SST. Flange pressure limits are per ANSI B16.5 for 316 SST

and material per SA182. Flange face finish per ANSI B16.5, 125 to

250 RMS. Pipe meets ASTM A312.

Bolts

SAE 429 Grade 8 (meets or exceeds ASTM A193 B7 requirements),

ASTM A193 Grade B7M, or ASTM A193 Grade B8, Type 304.

(Body bolts are supplied in the same material as specified for

mounting bolts.)

Gaskets/O-rings

Glass-filled PTFE.

Optional high temperature Inconel X-750.

Gaskets and O-rings must be replaced each time the Model 1195 is

disassembled for installation or maintenance.

Manifold

Stainless steel per A479 316SS, Hastelloy C per B575/C-276.

Assembly Process Connections

Threaded Connections:

½-, 1-, and 1½-in. NPT.

Socket-Weld:

ò

-, 1-, and 1

ò

-in.

Associated Piping:

½-in. SCH40 or 80, 1-in. SCH40 or 80, and 1½-in. SCH80. (Precision

bored for greater flow accuracy.)

Flanged Pipe:

ANSI Class 150, 300, and 600 RF.

DIN Flanges: DN15, DN25, DN40.

Bore Sizes

The bore sizes in Table 10-2 on page 10-3 are standard. Betas listed are

for assemblies with piping.

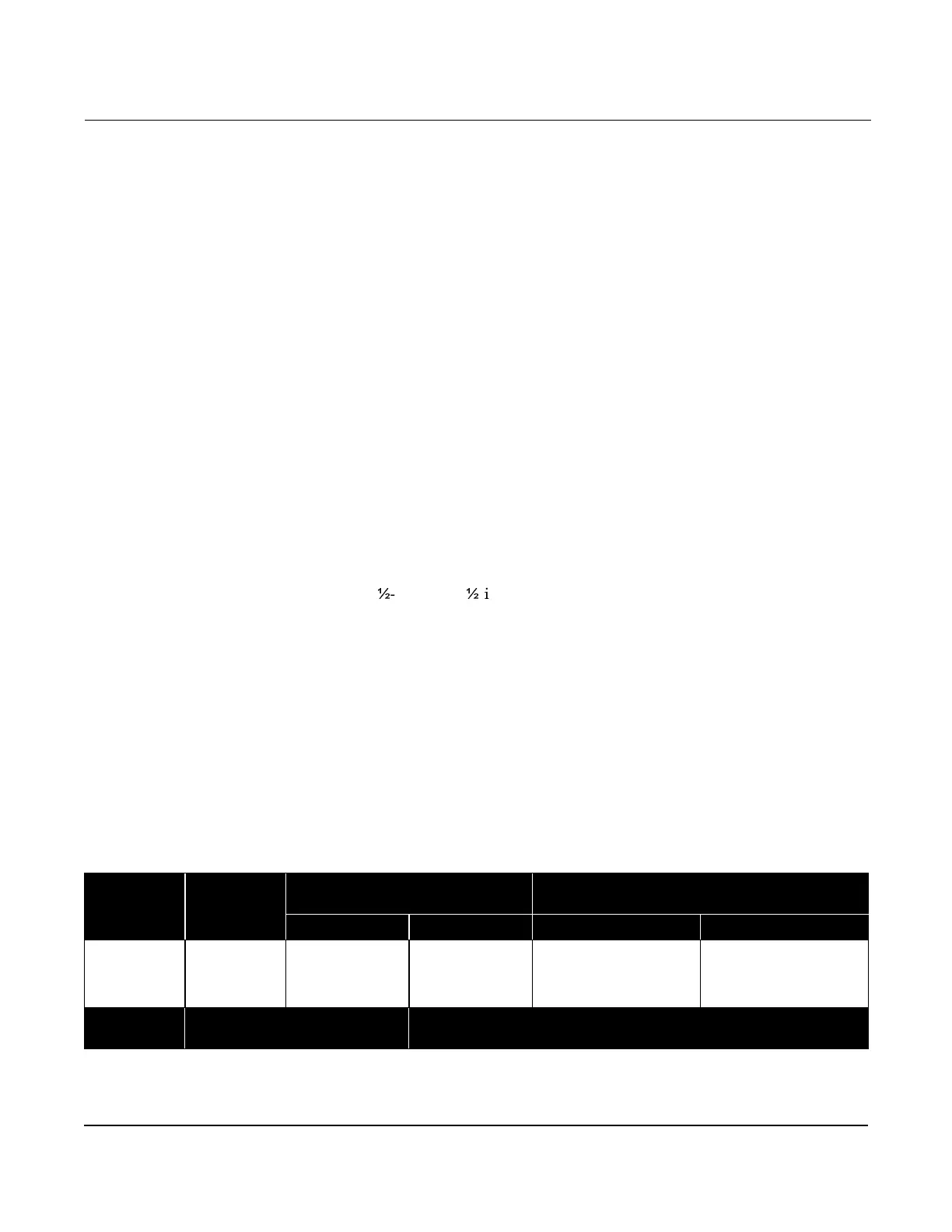

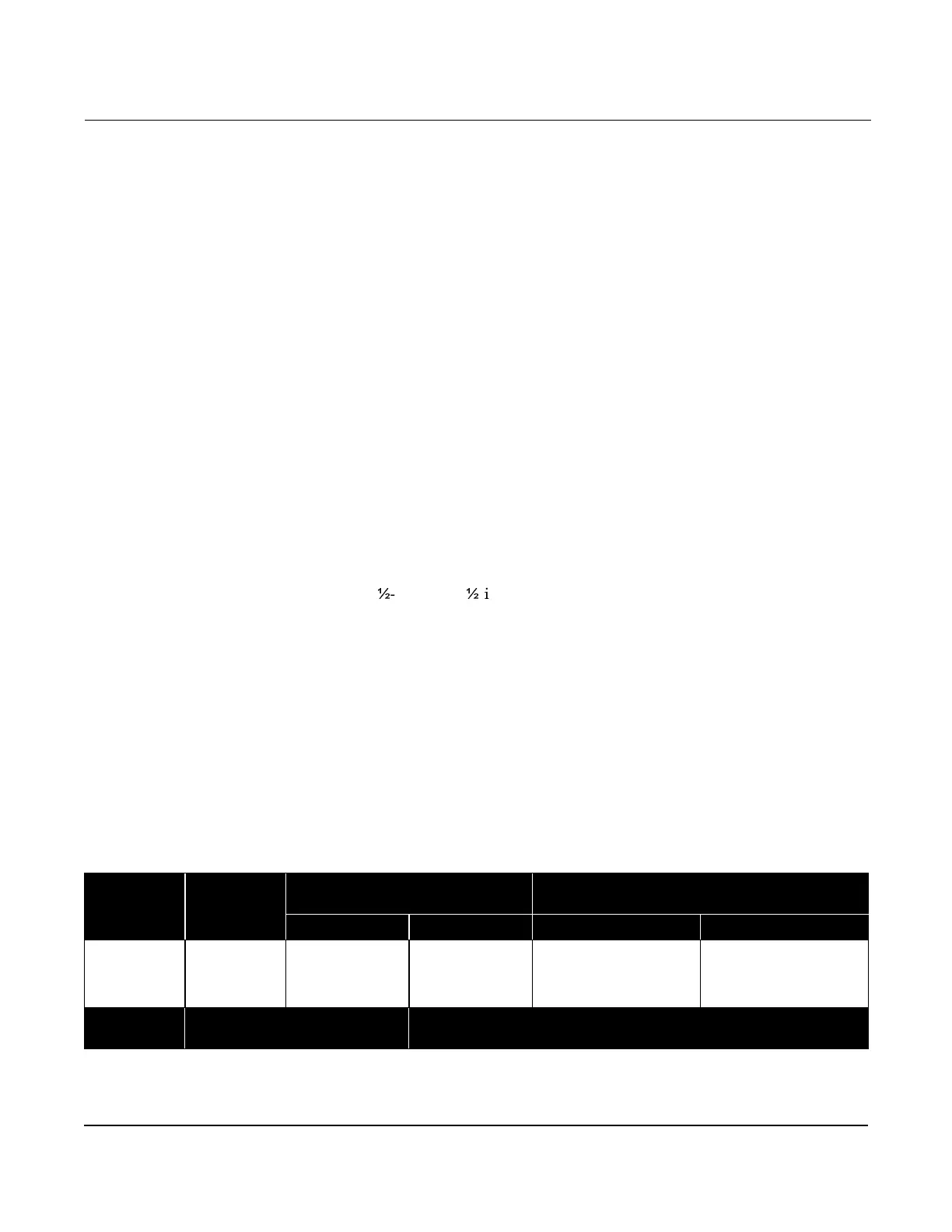

Table 10-1. Service and Flow Ranges

Line Size

in. (mm)

Plate Type

Liquids

Example is Water @ 60°F (15.6°C)

Gases/Vapors

Example is Air @ 500 psia (3448 kPa), 68°F (20°C)

GPM I/min SCFH m

3

/hr

½ (15)

½ (15)

1 (25)

1½ (40)

Quadrant

Square

Square

Square

0.001–0.1

0.047–7.0

0.18–41

0.7–95

0.004–0.4

0.15–26.5

0.68–155

2.65–360.0

0.75–300

30–8,800

115–55,000

450–125,000

0.021–8.1

0.9–250

2.9–1,575

11.7–3,650

Standard conditions: 14.696 psia (101 kPa),

60°F (15.6°C).

Loading...

Loading...