Status byte (byte x+4)

The structure of the status byte corresponds to the PROFIBUS PA prole. With the ET 200iSP, the

following status codes of the PROFIBUS PA prole are used:

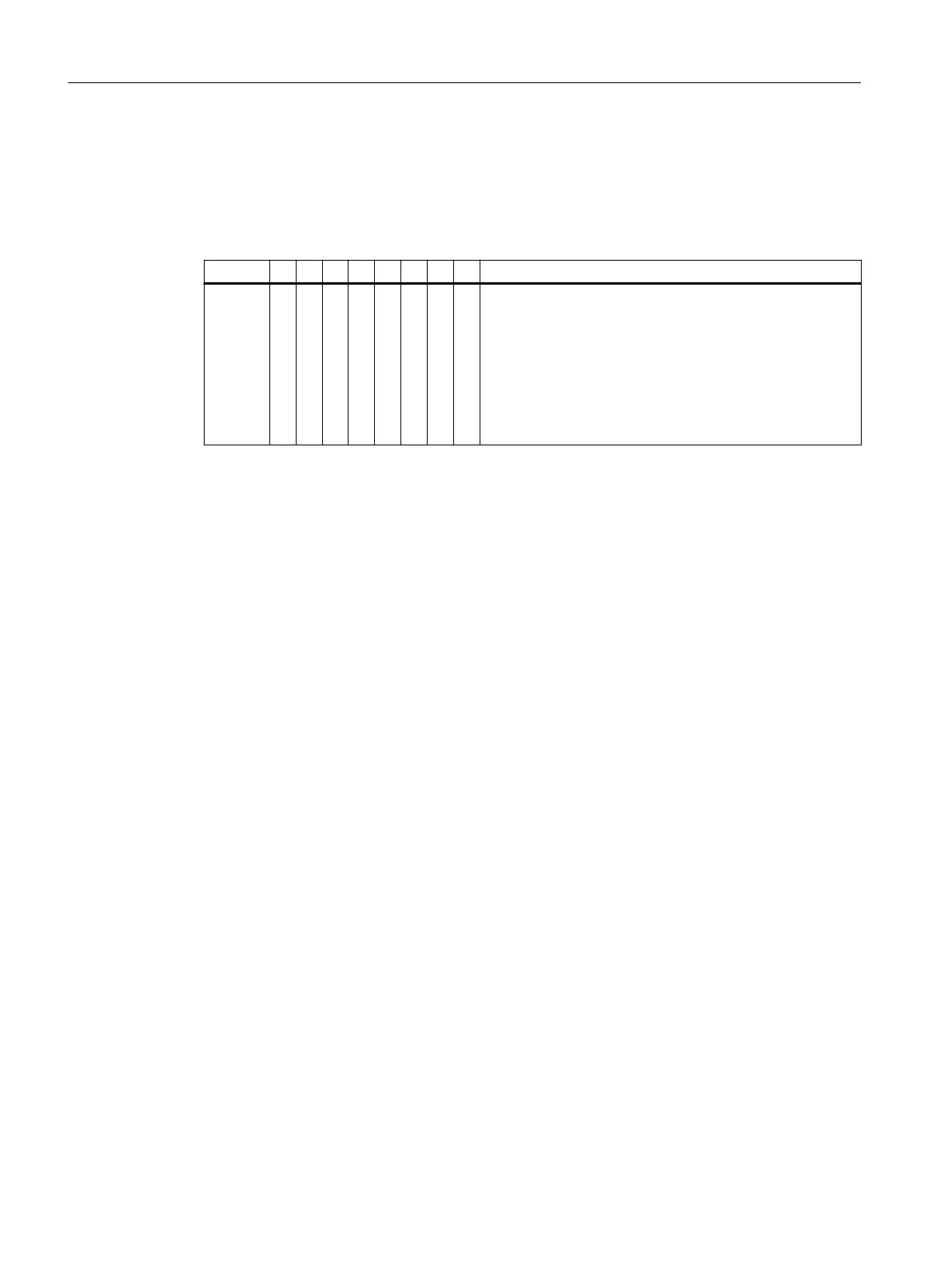

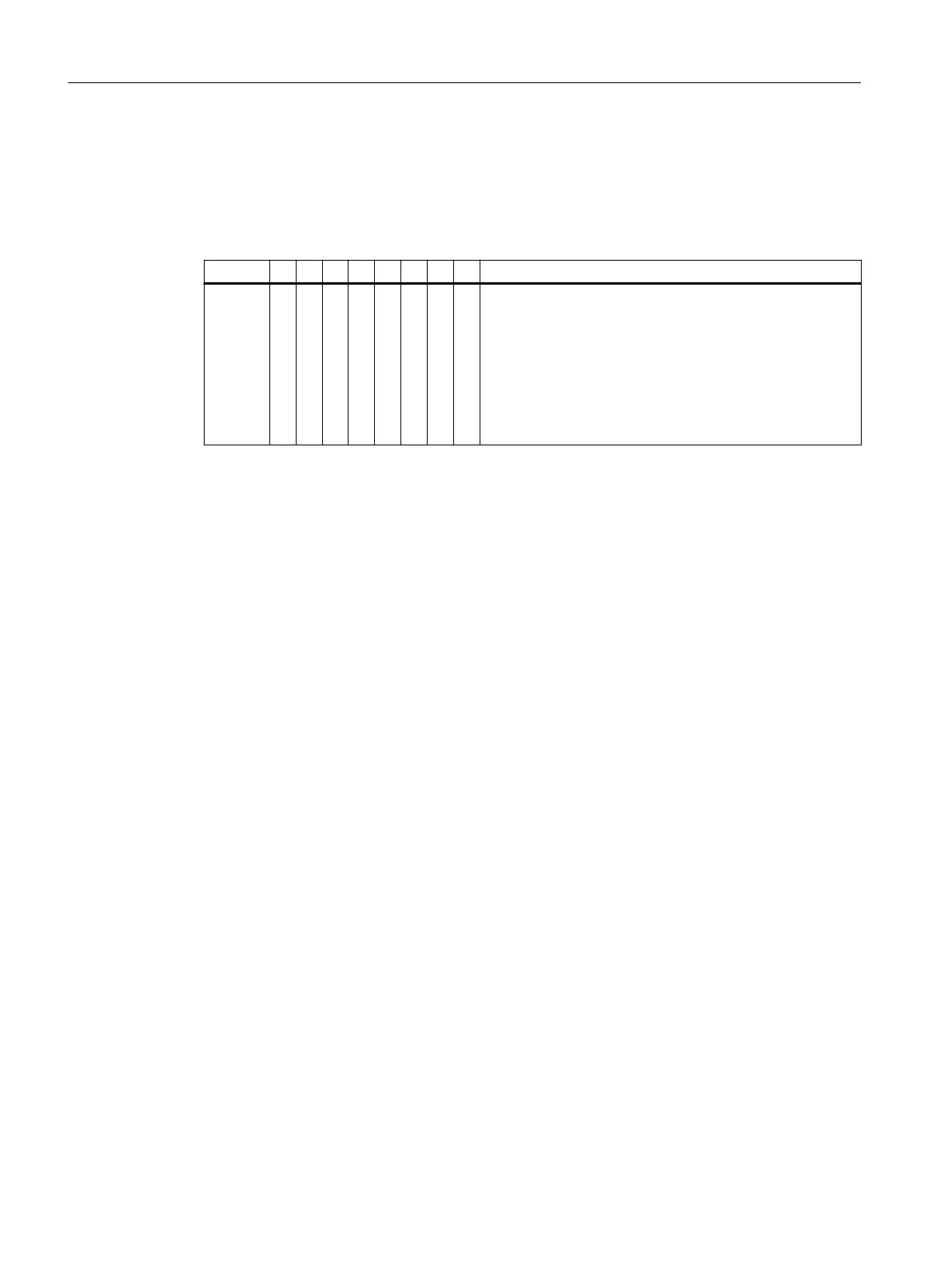

Table 14-37 Status byte

7 6 5 4 3 2 1 0 Description

Byte x+4 HART status byte for HART measured value 1, as specied for

HART

Bit 0 and Bit 1: Limits: Reports limit violations

Bit 2 to bit 5: Sub-status: dierentiates and renes the qual‐

ity of the associated measured value. Meaning depends on

"Quality". See operating instructions of the HART eld device

Bit 6 and Bit 7: Quality: Describes the basic quality of the

measured value

Status codes used by the PROFIBUS PA prole for ET 200iSP:

• 01001100 (4C

H

) uncertain, initial value (before rst contact)

• 00011000 (18

H

) bad, no communication (communication error)

• 00001100 (0C

H

) bad, device failure (device fault)

• 01000111 (47

H

) uncertain, last usable event, constant (device is busy)

• 10000100 (84

H

) good, update event (re-conguring)

• 10000000 (80

H

) good, ok (no error)

See also

Analog input modules with HART (4 AI I 2WIRE HART, 4 AI I 4WIRE HART) (Page 439)

Analog output module with HART (4 AO I HART) (Page 441)

14.10.8 HART data records

Requirements

You need this information if you go beyond the standard applications of STEP 7 and SIMATIC PDM

applications or use your own conguration tool for HART communication.

Data record interface

The analog modules with HART use data records as the input and output interface:

The mapping of the HART commands and HART responses into the PROFIBUS DP data records is

based on the PROFIBUS Prole HART Version 1.0. For more information on the HART protocol,

refer to the PROFIBUS DP HART Prole Application Guidelines.

Analog electronic modules

14.10 Basics of HART

ET 200iSP

398 Operating Instructions, 11/2022, A5E00247483-AK

Loading...

Loading...