Commissioning Manual

138 6FC5397-4EP10-0BA8, 07/2018

Note

The following tables list the PLC machine data used in the default PLC applications. The machine data not listed below is

reserved for the manufacturer.

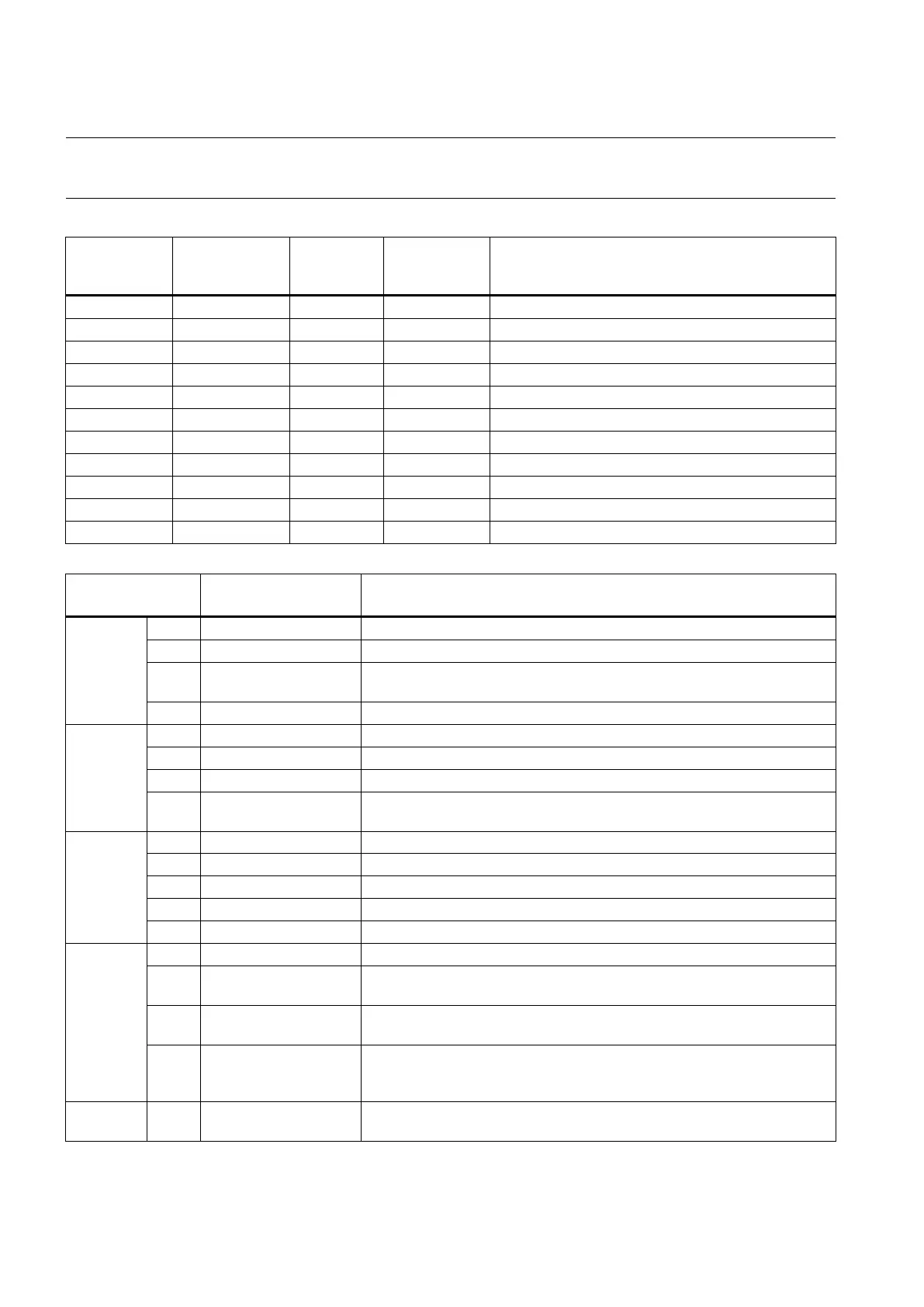

USER_DATA_INT

MD14510

Machine data -

Integer

Layout of the traverse keys

Spindle override 50% key holding on time defined

Spindle override 100% key holding on time defined

Feedrate override 0% key holding on time defined

Feedrate override 100% key holding on time defined

14510[22] DB4500.DBW44 0.1 s 30 to 200 Monitoring time when searching for tools

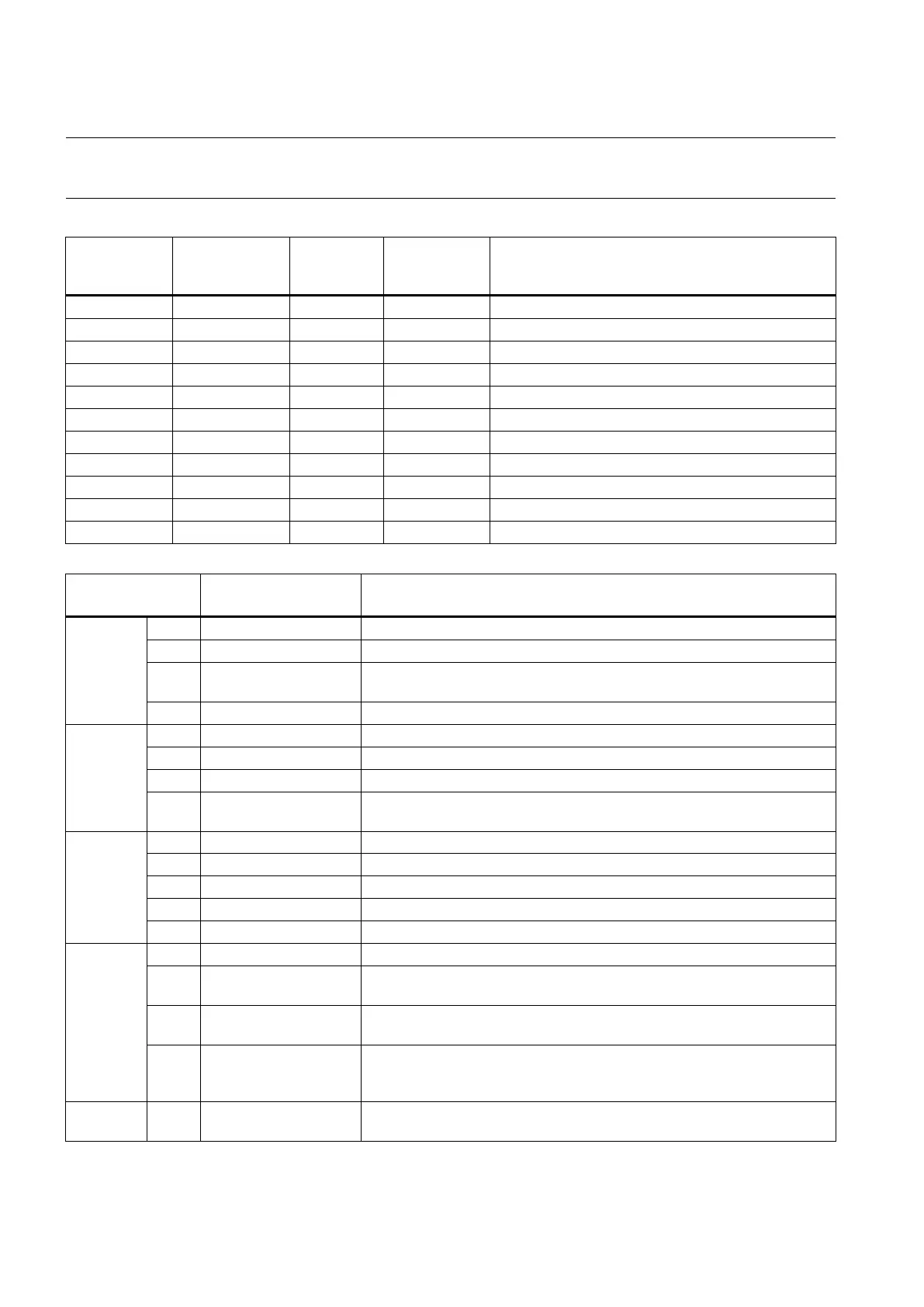

USER_DATA_HEX

MD14512

Machine data - Hex

14512[16] Bit 1 DB4500.DBX1016.1 Function of chip conveyor (milling)

Function of safety door (milling)

Bit 3 DB4500.DBX1016.3 When the function of safety door is active, it can be triggered by M01/M02

(milling)

Handwheel assignment with the MCP/HMI

14512[17]

Turret (turning); tool magazine (milling)

Clamping function (turning)

Tail stock function (turning)

Bit 3 DB4500.DBX1017.3 Selection between handwheel and hand-held unit (0: handwheel; 1: hand-

14512[18]

Automatic lubrication at power-on

External signal for spindle stop

The hardware limit is independent from a PLC program

Each feed axis has a hardware limit switch (activated when Bit 6 = 0)

14512[19]

Function of spindle braking

Bit 2 DB4500.DBX1019.2 Password clearing by power-on (0: delete the password; 1: do not delete

Bit 4 DB4500.DBX1019.4 Spindle speed selection in "JOG" mode (0: select the speed set in

MD32020; 1: select the speed set last time)

Bit 7 DB4500.DBX1019.7 Manual machine function (this function becomes active if you have in-

stalled licensed turning machine system and called it with a PLC subrou-

14512[20] Bit 0 DB4500.DBX1020.0 Grey coded switch (0: spindle override controlled by the grey code; 1:

spindle override controlled by triggering user keys)

Loading...

Loading...