Commissioning Manual

70 6FC5397-4EP10-0BA8, 07/2018

-mounted motors must have a stable motor suspension assembly and for high field weakening speeds must be

supported using the appropriate feet at the bearing end shield. For more information on foot/flange mounting, see Section

"

Mounting orientation and outline dimensions (Page 67)".

Support using feet at the bearing end shield is not required if the following conditions are maintained:

For flange-mounted motors, there is a stable motor suspension design.

The permissible vibration values according to DIN ISO 10816 are maintained.

The maximum speed is limited (see Section "SIMOTICS M-1PH1 main motors (Page 382)").

Motors that are mounted, as a result of their type of construction, to the wall using the motor feet, must be fixed in place

through the use of an adequately dimensioned positive form fit (for examp

le, studs or mounting rails).

When commissioning the motors, it must be ensured that the permissible vibration values according to DIN ISO 10816 are

maintained.

Note

Using the eyebolts

Lift the 1PH1 motor only at the eyebolts.

that the cooling air can enter and be discharged without any restrictions.

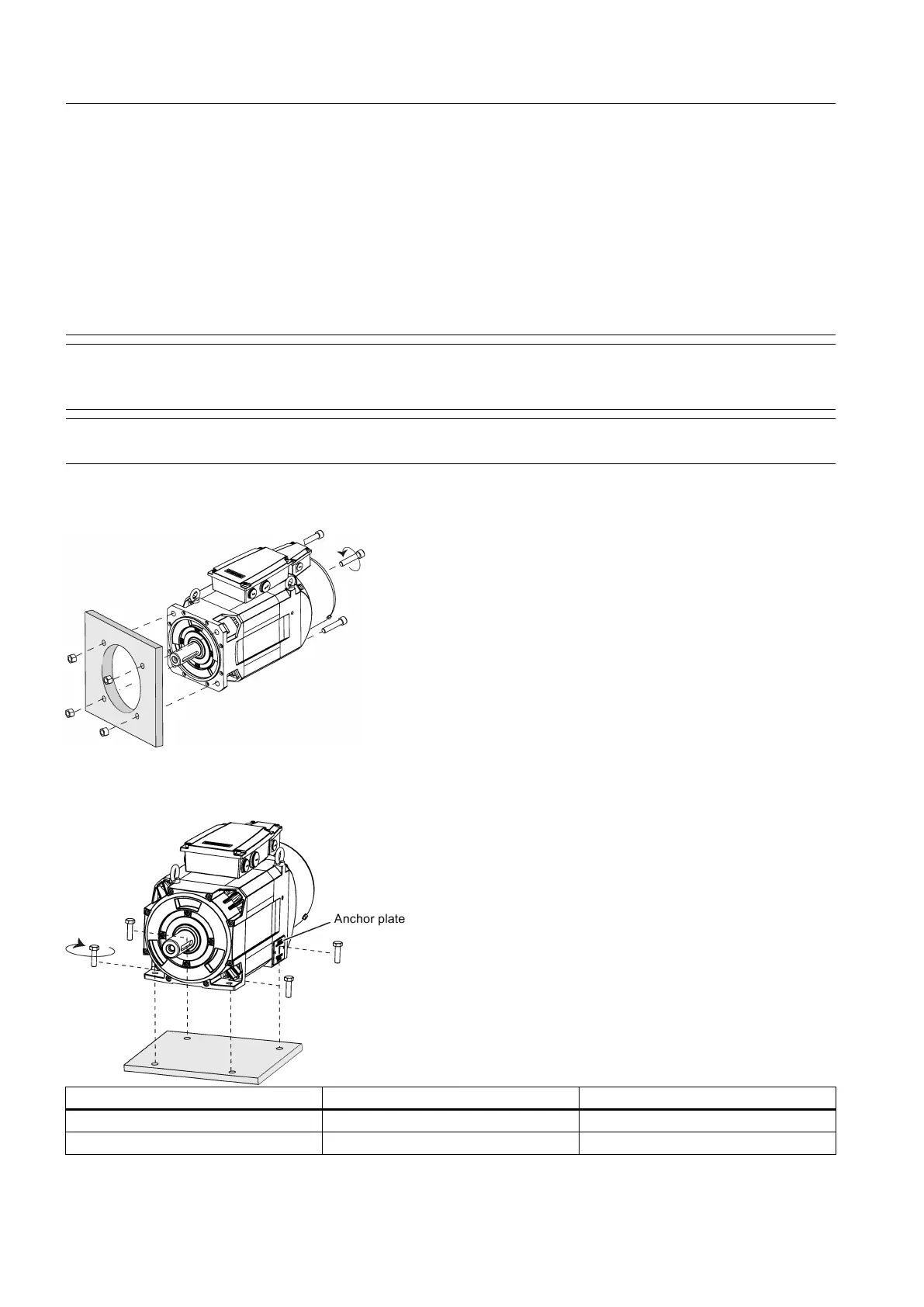

Mount the motor through a mounting steel flange. Use four M12 screws with a tightening torque of 84 Nm.

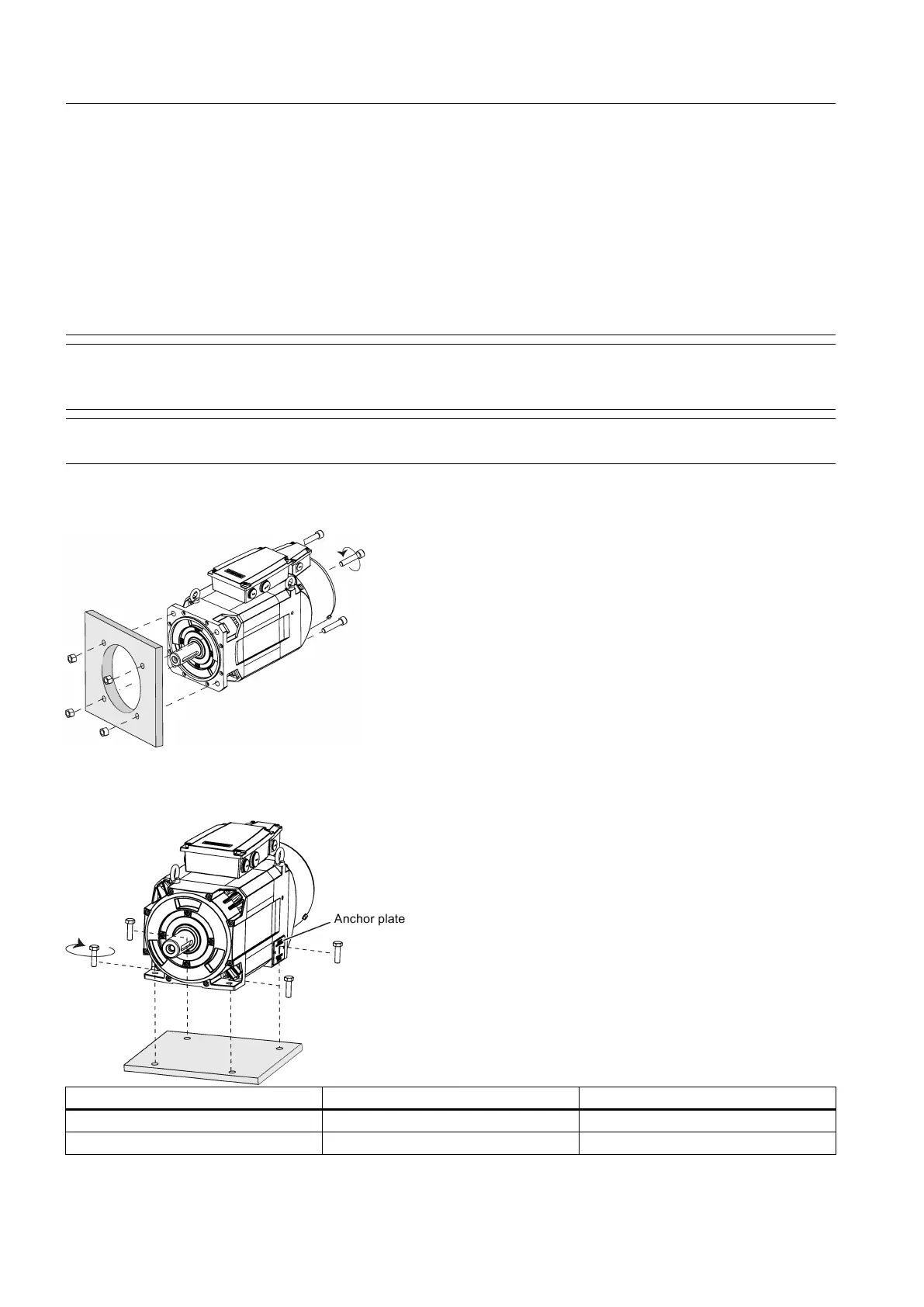

Remove the anchor plates with a wrench, fix the motor to the mounting plate with screws, and then reinstall the anchor

plates. You can use four screws to fix the motor as shown in the following figure:

Loading...

Loading...