User manual of EC160 elevator intelligent integrated machine Debugging at fast speed

158

state.

5. After proper multi-deck running, make the elevator run at multi-deck speed to the top and bottom

to check whether in normal state.

6. After proper top/bottom running, check the up forced deceleration switch distance and down

forced deceleration switch distance meet the requirements, and no top-hitting or bottom-clashing;

otherwise, adjust the distance.

Redo the hoistway autotuning after adjusting the up/down forced

deceleration switch.

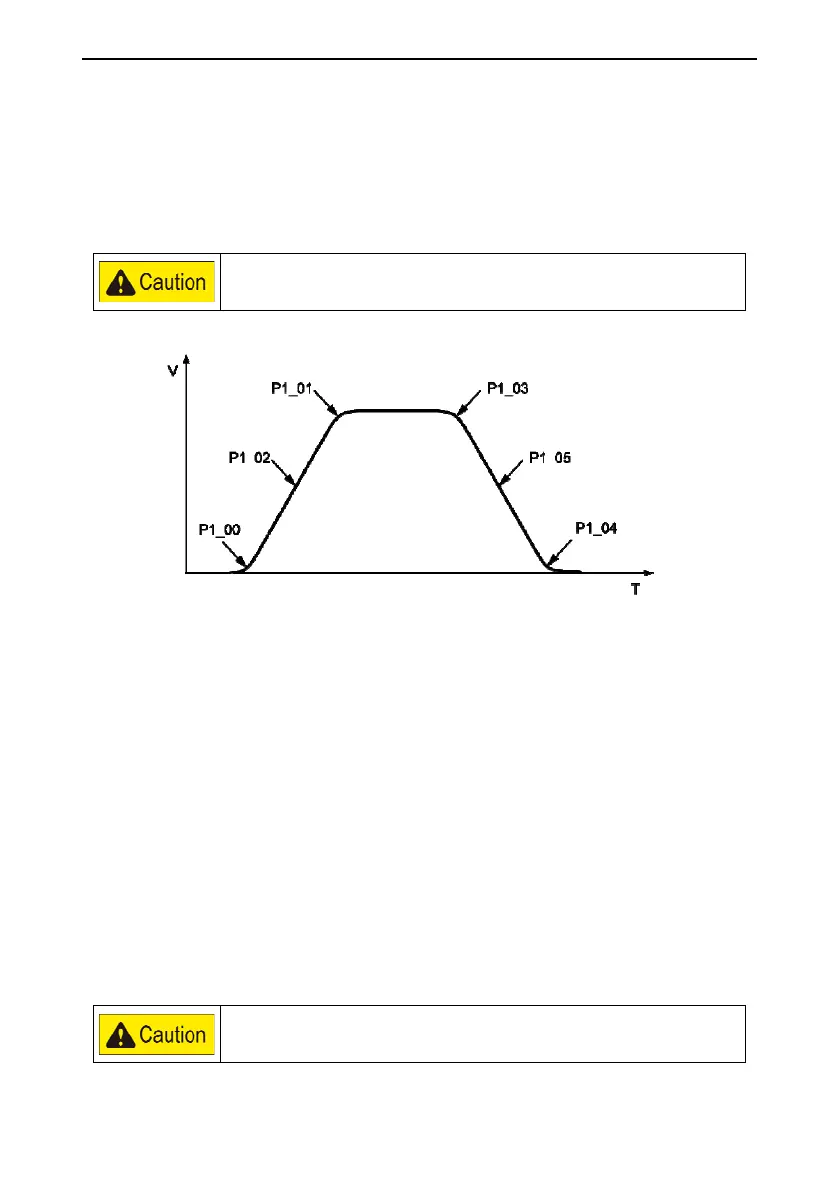

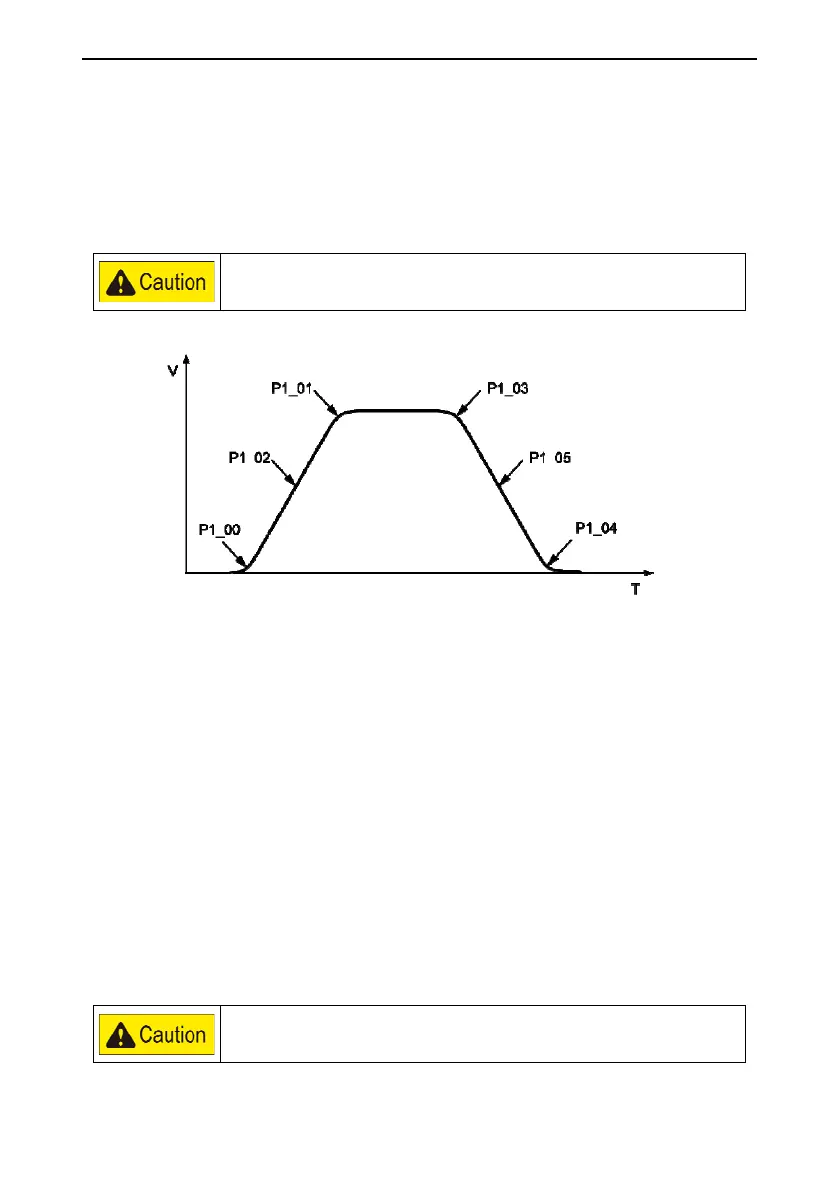

8.7 S Curve adjustment

Figure 8-1 S curve adjustment

8.8 Leveling adjustment

1. The leveling plate are plugged in the photoelectric switch or magnetic switch for about 2/3 and

check the depth of each plate are the same and as vertical as possible.

2. Keep the center of the plate and sensor is in one line when installation.

3. Record the distance between the car sill and hall sill when the elevator goes up/down to a floor.

4. Leveling adjustment: If the leveling overshoots at fast stop (stop running after reaching the

leveling line), enlarge the running distance of the elevator on the basis of original leveling

precision; if the leveling lacks (stop running before reaching the leveling line), reduce the

running distance of the elevator on the basis of original leveling precision.

5. Interference and bad quantity of the rotating encoder may affect the leveling precision.

Ensure the connection of the encoder is shield cable, and the shield layer needs to be grounded at

the end of the control cabinet. The connection of the encoder and the power cables can not route

in one trough.

Redo the hoistway autotuning after adjusting the leveling switch,

magnet vane or forced deceleration switch.

Loading...

Loading...