User manual of EC160 elevator intelligent integrated machine Product overview

18

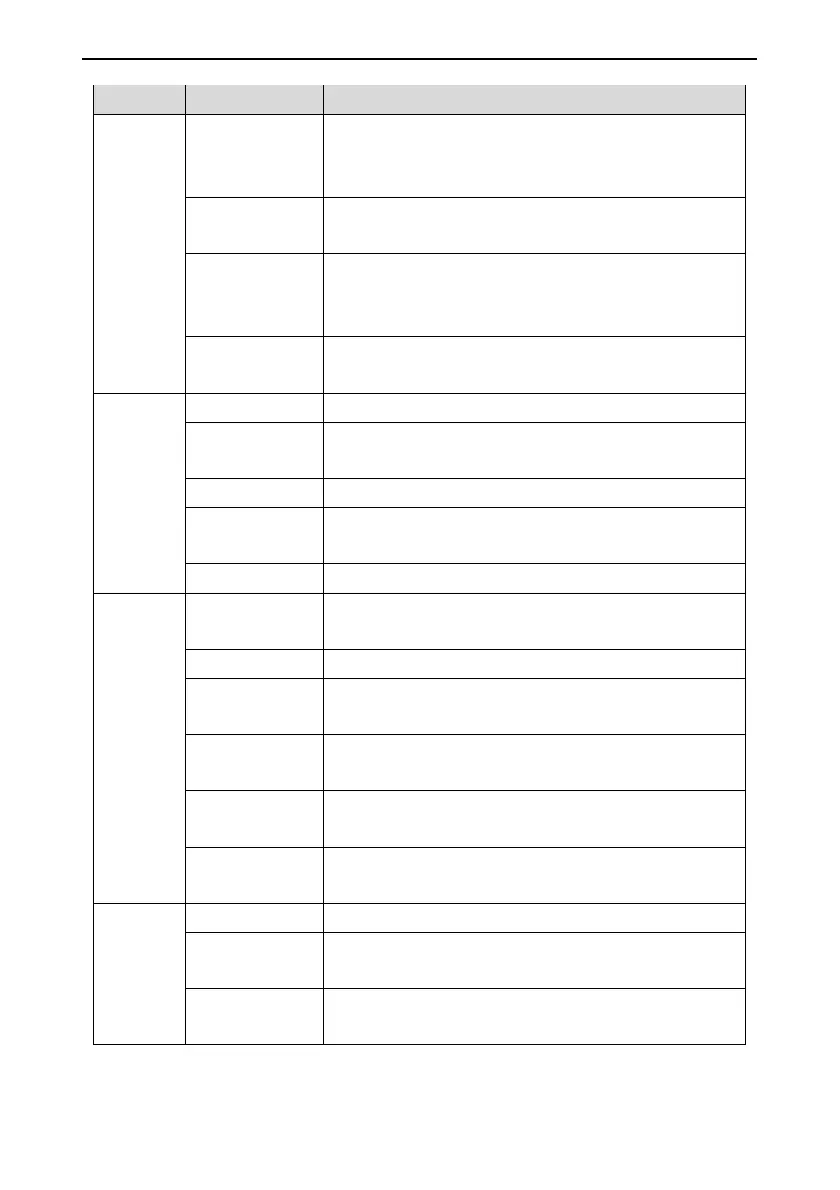

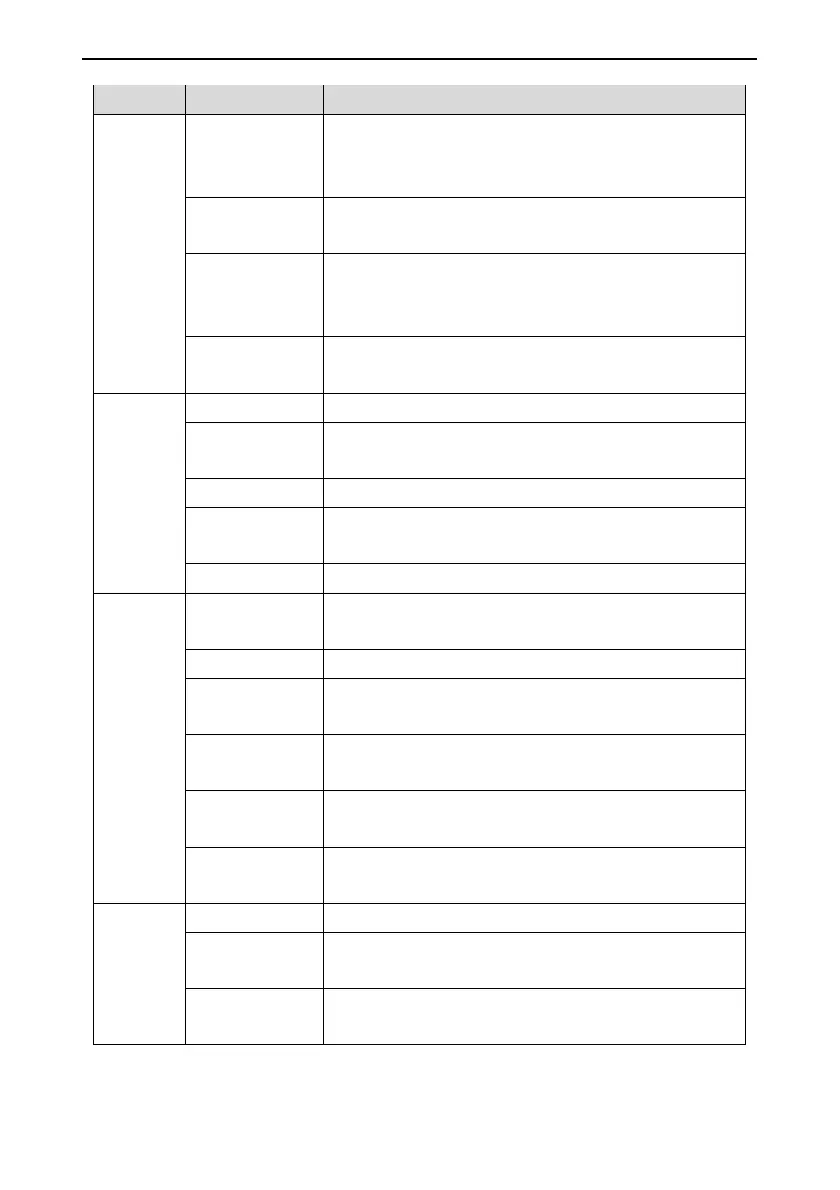

Item Name Specification

High voltage

inspection input

port

3 high voltage inspection input terminals, AC/DC 110V

Digital output port

6 digital output terminals, DC30V/5A, AC250V/5A, part of

output terminals can use programmable logic control

CAN

communication

interface

2 independent CAN communication terminals

Encoder interface

Built-in SIN/COS, collector NPN output, push-pull output

encoder interface, extensible Endat encoder interface

Tec hnica l

feature

Control mode PG vector control

Overload capacity

150% of rated current: 60s

180% of rated current: 10s

Starting torque PG vector control: 0Hz/150%

Speed control

precision

PG vector control: ±0.1% of the Max. speed

Carrier frequency 1.0kHz~16.0kHz

Function

feature

Running mode

Fast speed mode, inspection mode, returning to leveling

mode, leveling after opening mode and UPS mode

Stopping mode Stop at the distance control principles

Starting torque

compensation

Apply speed loop and position loop

Smooth starting without weighing devices

Master autotuning

mode

Static and dynamic autotuning

Hoistway

autotuning mode

Record the position of floor and forced deceleration switch

Auto-voltage

adjustment

Keep the output voltage constant when the voltage of grid

changes

Operation

and

monitoring

Operator keypad 2-digit LED, 8 lights and 2 buttons, for fault inquiry

Manual controller

Parameters setting, upload, download and fault inquiry and

manual calling

Software of upper

computer

Parameters setting, upload, download and fault inquiry,

manual calling and curve monitoring

Loading...

Loading...