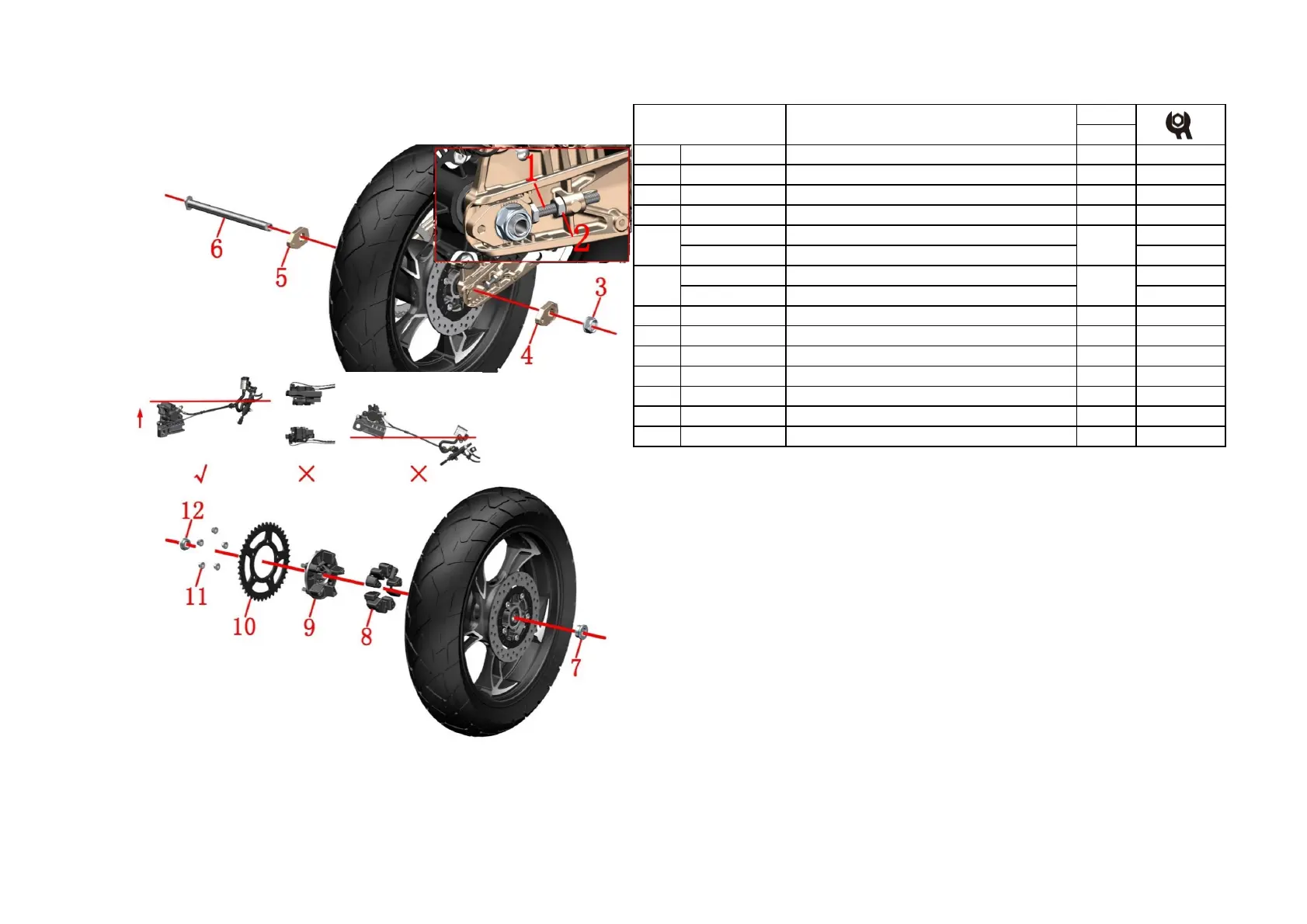

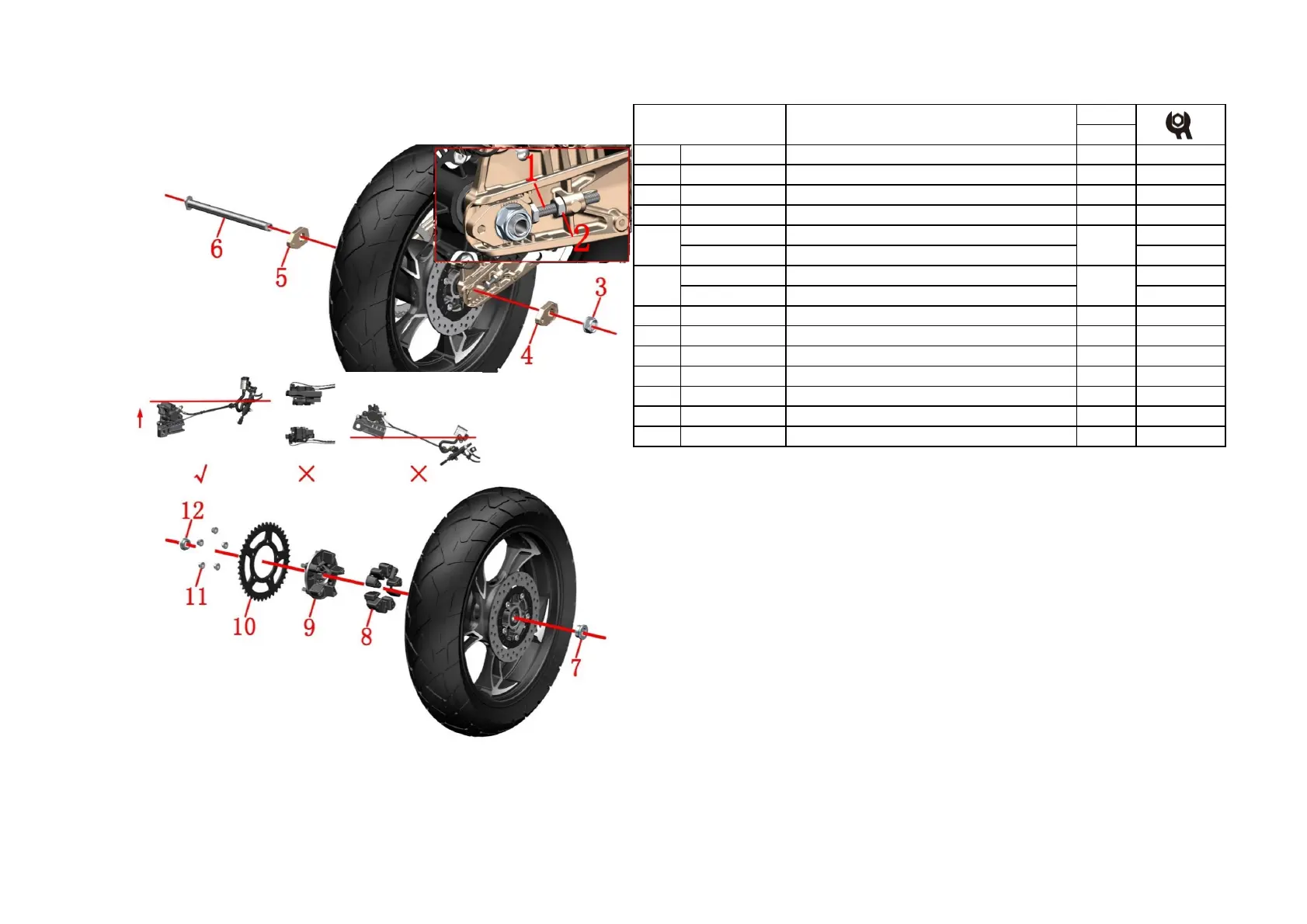

4、REAR WHEEL COMPONENT 25

CHK

AD

J

NO. PART NO. PART NAME QTY CAUTION

1 1251100-105000

Chain adjuster bolt M10×70

(

)

2 1251300-050000

(

)

3 1251300-067000 ZT250-RRear wheel hollow shaft nut 1 110N.m

1032142-073035 ZT310 Right chain adjuster(Titanium)

1032142-075051 ZT310 Right chain adjuster(dark gray matte)

1032142-072035 ZT310 Left chain adjuster (Titanium)

1032142-074051 ZT310 Left chain adjuster (dark gray matte)

6 1094100-032000 ZT250-R Rear wheel hollow shaft nut 1

7 1274200-002000 ZT310Rear wheel right sleeveφ20×φ28×φ38×18.5 1

8 1244200-050000

-

T Sprocket cushion rubber

5

9 1094200-011000

-

R Second generation sprocket seat

1

10 1080100-068000

-

-

11 1251300-057093 Non-standard nut M10×1.5(Dacro) 5 45±3N.m

12 1274100-106000

-

R rear wheel left sleeveφ20×φ30×φ35×12.9

1

Fig.7 REAR WHEEL

COMPONENT

Rear wheel component 1

●Rear wheel assembly

Disassemble rear wheel axle nut ⑶ with socket sleeve.

Use open spanner to move chain adjuster nut ⑵ on both sides towards rear wheel axle until they reach chain

adjusting bolt ⑴. Then rotate the bolt and nut towards motorcycle front direction till the end.

Push rear wheel assembly towards motorcycle front direction and take off the chain from sprocket.

Hold the rear wheel assembly. Punch rear wheel axle ⑹ with rubber hammer. Take off right chain adjuster ⑷,

right axle sleeve ⑺, rear tire and rim assembly, left axle sleeve ⑿, left chain adjuster ⑸. Tie firmly the rear disc

brake clamp and avoid it to be lifed higher than disc brake oil cup. Disassemble the rear wheel axle at last.

●Sprocket bracket assembly

Put down the rear wheel assemble horizontally. Take off nut ⑾ with socket sleeve. Take off sprocket ⑽;

sprocket bracket ⑼. Pull out the sprocket gum cushion ⑻ from the rim.The oil seal type of the sprocket seat is

φ52×φ30×7;Bearing type: 6205.

CAUTION:

●Use suitable tool to support the motorcycle. Avoid accidents caused by falling motorcycle. Single person

manipulation is prohibited.All the standard parts need to reach standard torque while reassembling.

●Using iron hammer to punch rear wheel axle, disc brake clamp assembly is prohibitd.

●While disassembling the rear wheel assemble, avoid the rear disc brake clamp to be lifted higher than the disc

brake oil cup. If not, air will get into the tubes and cause softness or failure on braking system. As disc brake

tubes request extreamly high vaccum degree. Make sure manipulator has maintenance ability before

disassembling the disc brake assembly.

4

5

1

1

●Check the chain regularly. Clean the chain every 1500km is suggested. Keep the tightness of chain to

be in a suitable range. Too loose chain have possibility to separate from sprocket or damage the engine.

Too tight chain can be worn out quickly.

Loading...

Loading...