80209C_MHW_850-1650-1850_20-2020_ENG_pag. 23

2.2. Connections

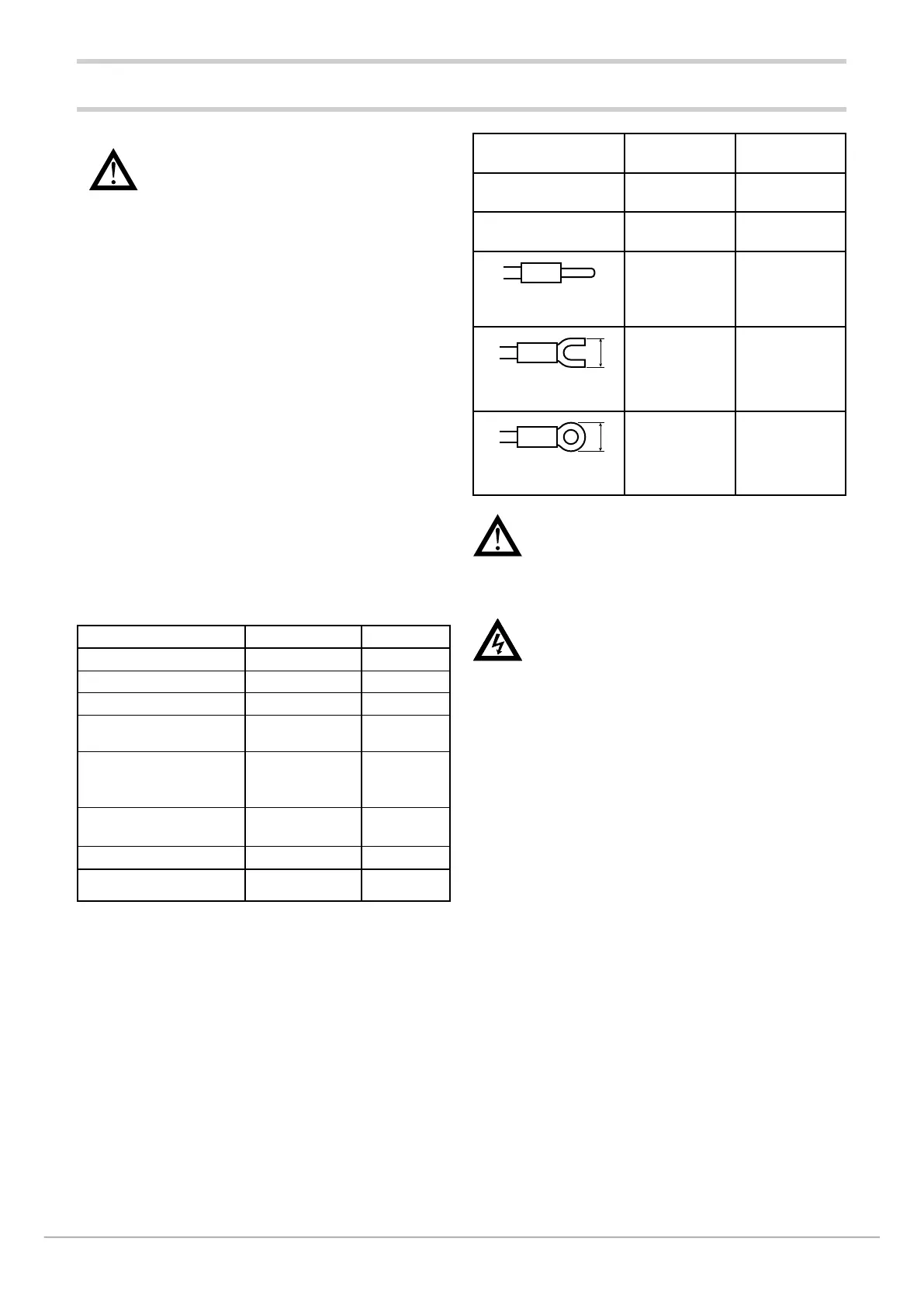

Cable / terminal

Cable / termi-

nal section

Terminal size

Rigid cable 0,8...2,5 mm

2

(18...14 AWG)

Twisted 0,8...2,5 mm

2

(18...14 AWG)

Tag terminal

(to be crimped)

0,25...2,5 mm

2

(23...14 AWG)

5,8

Fork terminal

(to be crimped)

5,8 mm max

5,8

Ring terminal

(to be crimped)

5,8 mm max

Attention! Anchor the cables, at least in pairs, so

that mechanical stresses do not discharge on the

terminal connections.

2.2.4. Power supply

Attention! Before powering the controller, make

sure that the supply voltage matches the one

shown on the controller data plate.

Because the controller does not have a switch, a bipolar

switch with fuse must be inserted upline. The switch, or

isolator, must be positioned in the immediate vicinity of the

device and must be easily reached by the operator.

A single switch can control multiple controllers.

The controller must be powered by a line separated from

the one used for electromechanical power devices (relays,

contactors, solenoids, etc).

It is advisable to install a ferrite core on the power line,

as close as possible to the device, to limit the controller’s

susceptibility to electromagnetic noise.

If the controller’s power line is heavily disturbed by the

switching of thyristor power units or by motors, it is advisable

to use an isolation transformer only for the controller,

grounding the shield.

Use appropriate line filters in the vicinity of high-frequency

generators or arc welders.

Use a voltage stabilizer if there are wide shifts in line voltage.

20...27 VAC/VDC models must be powered by a class II or

low-voltage limited-energy source.

The power supply must use a line separated from the one

used for electromechanical power devices, and low-voltage

power cables must run along a path separated from the

system or machine power cables.

Attention! Failure to follow the instructions in

this section may cause problems in electrical

safety and electromagnetic compatibility, in

addition to voiding the warranty.

2.2.1. General rules for connections

1. Connected external circuits must have double isolation.

2. In case of shielded cables, the shield must be grounded

at a single point, possibly near the controller.

3. Input cables must be physically separated from power

cables, output cables, and power connections.

4. Do not connect unused terminals.

5. Tighten the terminals without forcing. Loose terminals

may cause sparks and fires.

The recommended tightening torque is 0.5 Nm.

6. When making connections, respect polarity where

required.

7. Do not bend or twist the cables beyond the limits

specified by the manufacturers.

8. After connecting the cables, apply the transparent cover

to protect the terminals.

The terminal teeth limit and define the correct direction

for applying the cover.

2.2.2. Electromagnetic compatibility (EMC)

For electromagnetic conformity, the strictest general rules

have been applied, using the following test configuration:

Connection Cable section Length

Power supply

1 mm

2

1 m

Relay

1 mm

2

3,5 m

Serial port

0,35 mm

2

3,5 m

Thermocouple

0,8 mm

2

5 m

compensated

Potentiometer, linear,

“PT100” resistance

thermometer

1 mm

2

3 m

Analog retransmission

output

1 mm

2

3,5 m

Digital input/outputs

1 mm

2

3,5 m

Ethernet port

UTP 4x2xAWG24

cat 6

4 m

2.2.3. Cables

Always use cables appropriate for the voltage and current

limits specified in the Technical Characteristics.

Use copper cables with 60/75°C insulation.

Use twisted and shielded cables for non-power connections.

The controller’s terminal board has screw terminals (M3) that

accept stripped cables and crimped terminals for a tighte-

ning torque of 0.5 N m.

Two ring or crimped fork terminals can be connected on

each terminal

The following table shows the characteristics of the cables

and terminals that can be used.

Loading...

Loading...