20 June 2005 SERVICE PROGRAM MODE TABLES

5-17

Service

Tables

SP3-xxx: Process

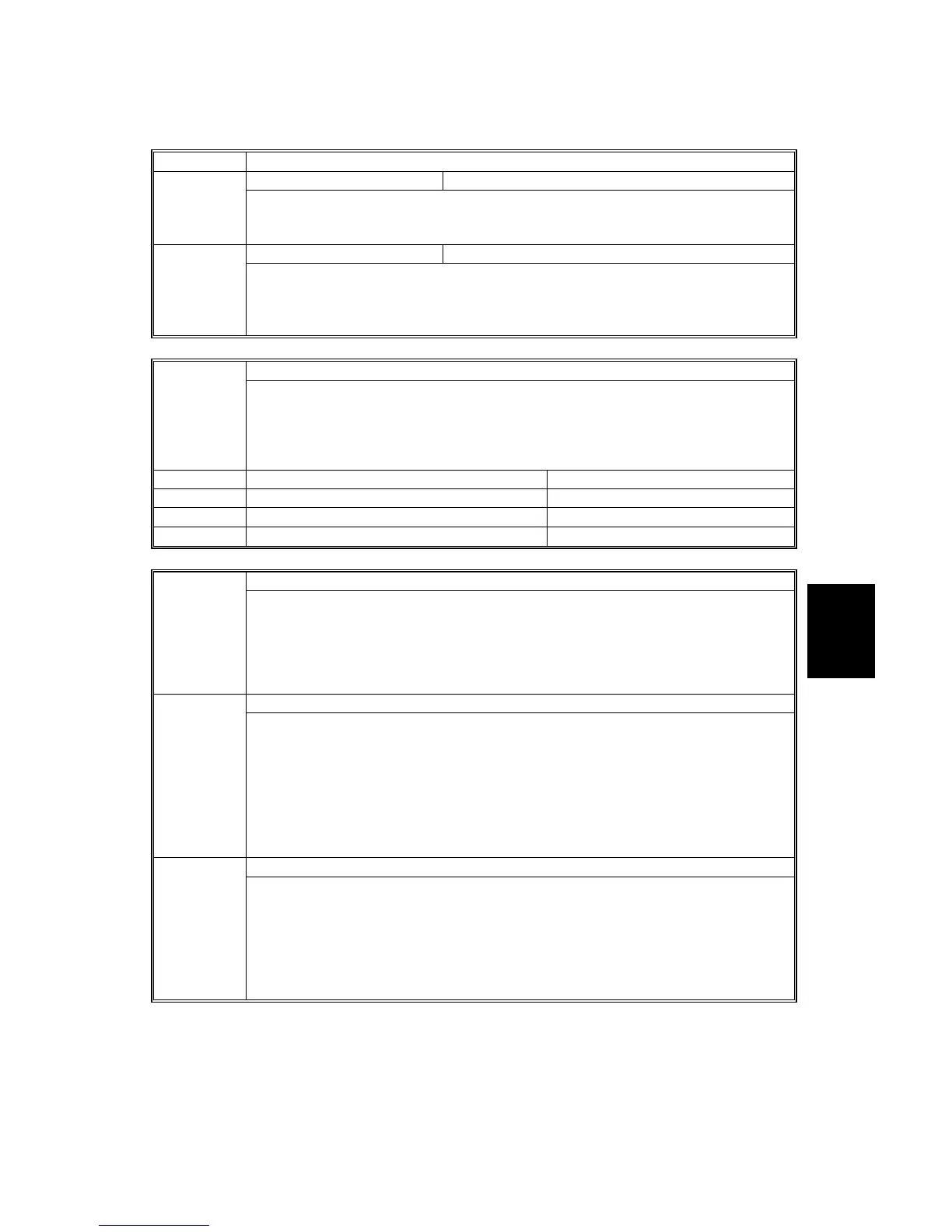

3001* ID Sensor Initial Setting

ID Sensor PWM Setting [0 ~ 255 / 100 / 1 step] 3001 1

Allows you to reset the PWM of the ID sensor LED to avoid a service call error

after clearing NVRAM or replacing the NVRAM.

The PWM data is stored by executing SP-3001-2.

ID Sensor Initialization — 3001 2

Performs the ID sensor initial setting. ID sensor output for the bare drum (V

SG) is

adjusted automatically to 4.0 ±0.2 V.

Press “Execute” to start. Perform this setting after replacing or cleaning the ID

sensor, replacing the drum, or clearing NVRAM.

ID Sensor Output Display 3103*

Displays the current V

SG, VSP, VSDP, and grayscale control.

If the ID sensor does not detect the ID pattern, “V

SP = 5.0 V/VSG = 5.0 V” is

displayed and an SC code is generated.

If the ID sensor does not detect the bare area of the drum, “V

SP = 0.0 V/VSG =0.0

V” is displayed and an SC code is generated.

3103 1* Vsg (Drum Surface Output) [0V ~ 5.00V]

3103 2* Vsp (Pattern Output) [0V ~ 5.00V]

3103 3* Vsdp (Immediate Post-Pattern Output). [0V ~ 5.00V]

3103 4* Vsm/Vsg (Grayscale Post-Pattern Output) [0V ~ 5.00V]

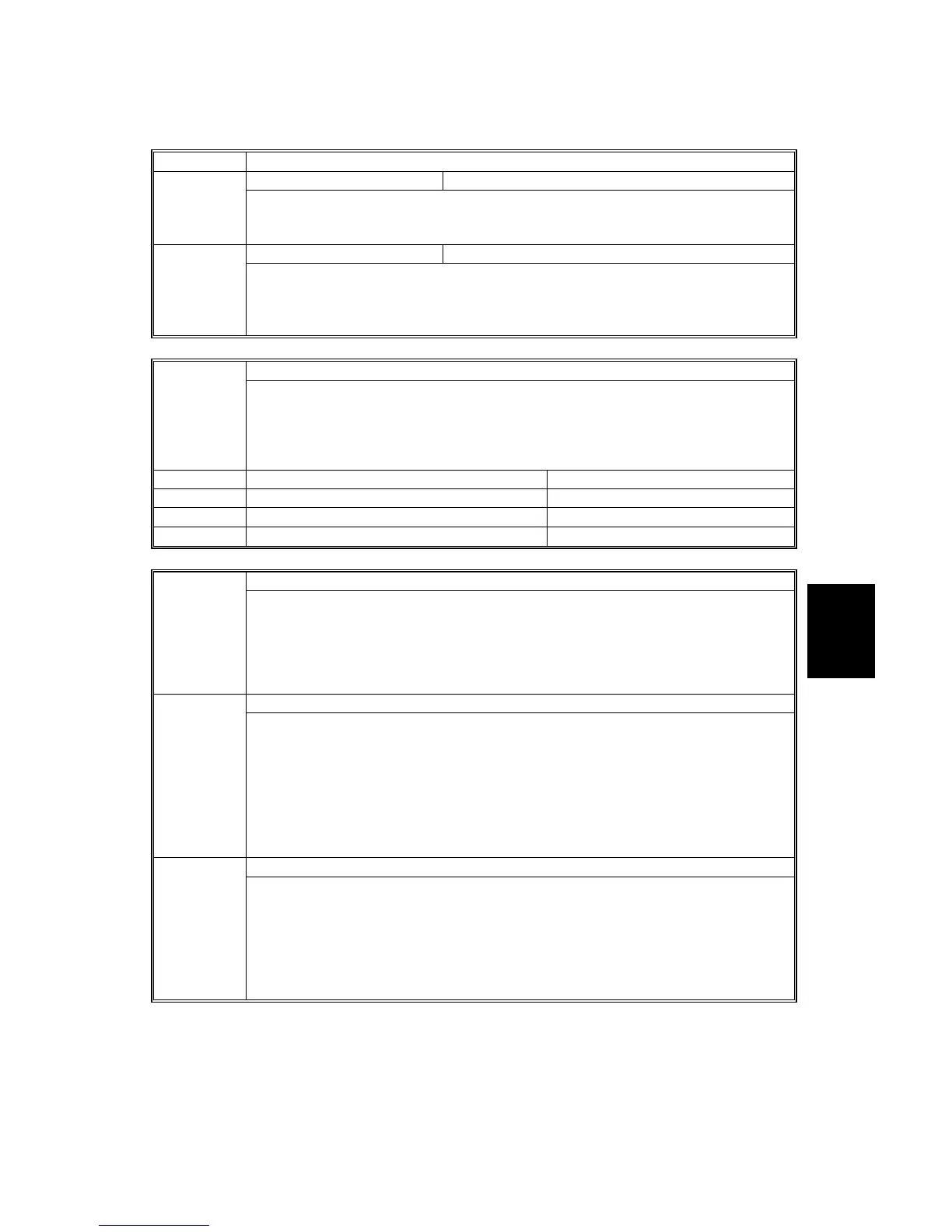

Hot Roller Stripper Cleaning After Job 3905*

Toner and carbon clinging to the hot roller strippers can cause poor print quality.

To prevent this, toner and carbon are dislodged from the hot roller strippers in two

ways: 1) switching the fusing motor on/off after every print job, and 2) freely

rotating the hot roller for 5 s at the beginning of every print job. These SP set up

operation of the first method (switching the fusing motor on/off after a print job.)For

details, see Section “6.6.2 Hot Roller Stripper Cleaning”. Also see SP 5959.

Number Rotations 3905 1*

This SP sets the number of times the 1st Cleaning is done for the number of

pages prescribed with SP3905 002 have been printed.

[0.0~1.0/1.0/0.1]

Note:

• All fans remain on during cleaning and then switch off 60 sec. after the

cleaning cycle ends.

• Raising this setting can increase wear on the hot roller and cleaning roller and

shorten the service life of the hot roller.

Number of Pages 3905 2*

This SP prescribes the number of pages to accumulate before the fusing motor is

switched on/off (1 cycle).

[0 ~ 1000 / 5 / 1]

Unless you change this setting, 15 sec. after a total of 5 pages have been printed

(the accumulated total of several small jobs), the fusing motor will switch on for 15

sec. and then switch off. This 15 sec. off/15 sec. on at the end of a cleaning job is

the 1st Cleaning.

Loading...

Loading...