INSPECTION AND REPAIR

5-32

ENG

PISTON RINGS

1. Measure:

•

Side clearance of rings

Use a thickness gauge.

Out of specification ➔ Replace piston.

NOTE:

Before measuring side clearance, remove carbon

deposits from the piston ring seats and from the

rings themselves.

Piston ring side clearance

(installed):

Upper ring 0.04 ~ 0.08 mm

Lower ring 0.03 ~ 0.07 mm

<Limit>: 0.13 mm

Oil scraper 0.02 ~ 0.06 mm

Piston ring end gap

(fitted into cylinder):

Upper ring

0.30 ~ 0.45 mm

<Limit>: 0.7 mm

Lower ring

0.30 ~ 0.45 mm

<Limit>: 0.8 mm

Oil scraper (tracks) 0.20 ~ 0.70 mm

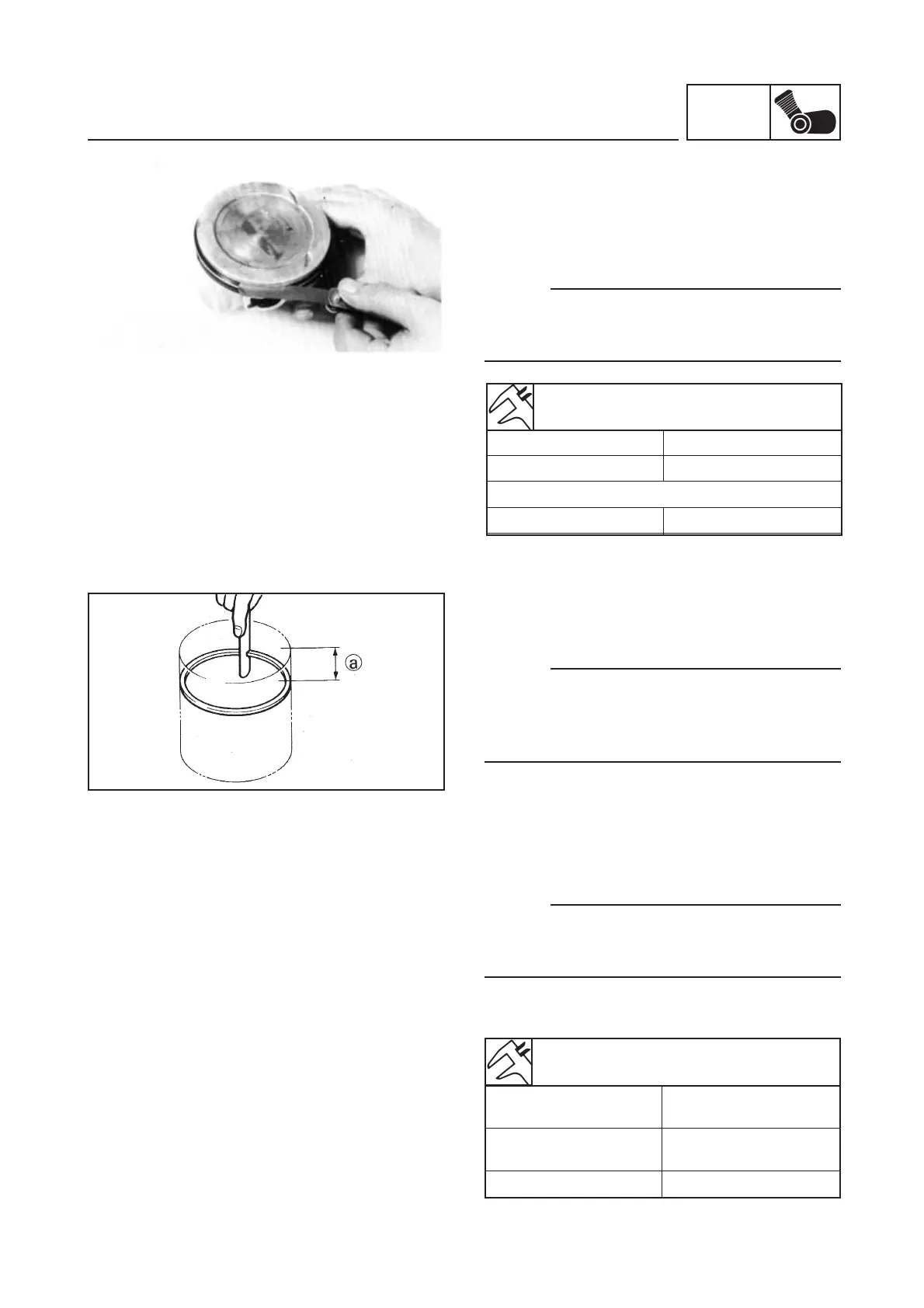

2. Install:

•

Ring (into the cylinder)

NOTE:

Fit each ring into the cylinder and push it to about

20 mm from the top edge of the cylinder. Push the

ring into the cylinder with the piston so that it is

perfectly perpendicular to the cylinder axis.

(a) 20 mm

3. Measure:

•

Ring end gap

Out of specification ➔ Replace.

NOTE:

It is impossible to measure the oil scraper end

gap. If the oil scraper port appears too large,

replace all three rings.

Loading...

Loading...