CRANKCASE

5-71

EAS30389

DISASSEMBLING THE CRANKCASE

1. Place the engine upside down.

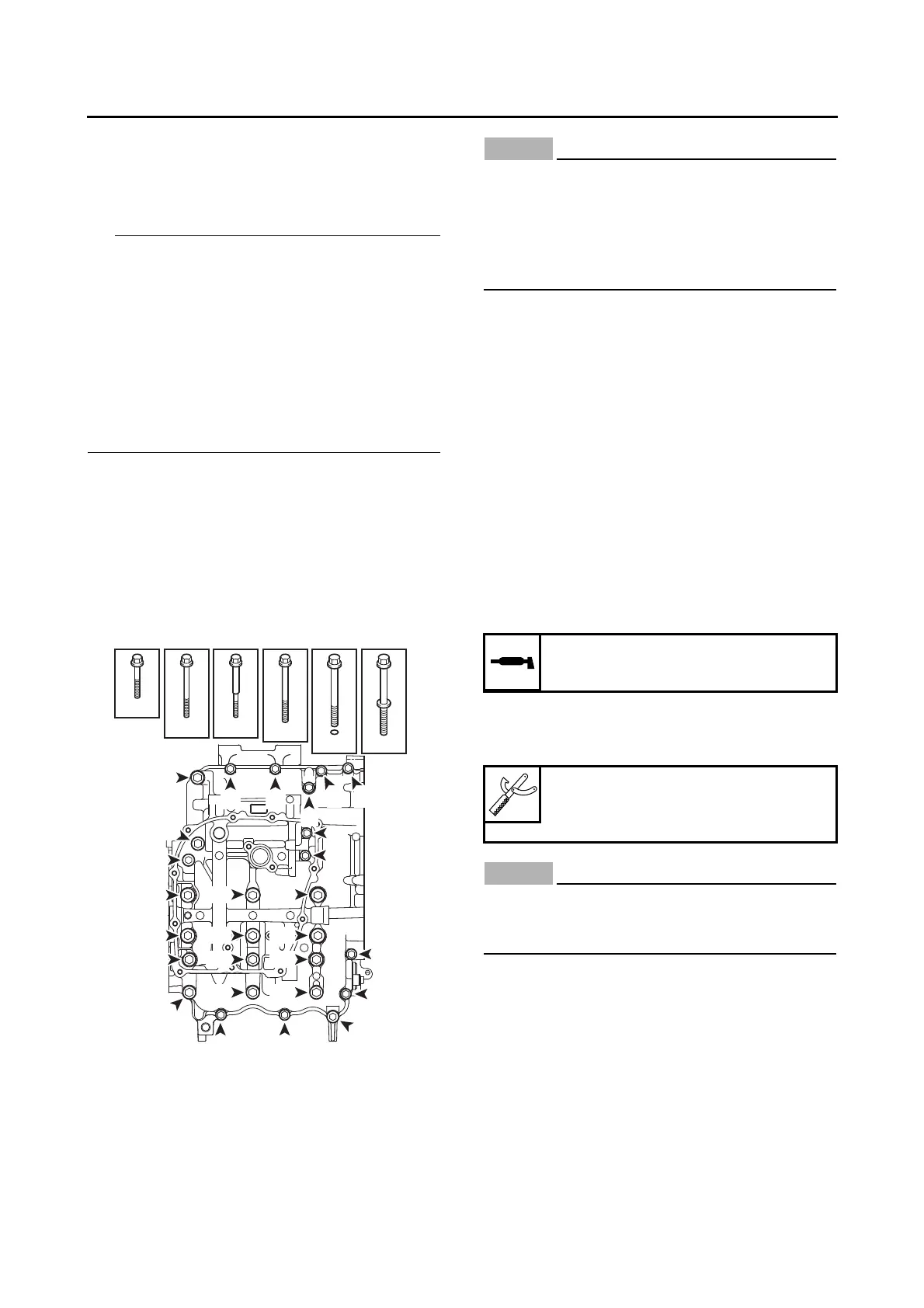

2. Remove:

• Crankcase bolt (×27)

• Loosen each bolt 1/4 of a turn at a time, in stag-

es and in a crisscross pattern. After all of the

bolts are fully loosened, remove them.

• Loosen the bolts “1”–“11” in any loosening se-

quence.

• Loosen the bolts “12”–“27” in the proper se-

quence as shown.

• The numbers embossed “1”–“16” on the crank-

case indicate the crankcase tightening se-

quence.

•M6 × 40 mm bolt (×8): “1”, “2”, “4”–“7”, “10”,

“11”

•M6 × 60 mm bolt (×3): “3”, “8”, “9”

•M6 × 65 mm bolt (×2): “12”, “13”

•M8 × 65 mm bolt (×2): “14”, “15”

•M8 × 70 mm bolt (×6) (bolts with O-rings):

“16”– “21”

•M9 × 80 mm bolt (×6) (bolts with washers):

“22”–“27”

3. Remove:

• Crankcase

• Dowel pins

ECA13900

Tap on one side of the crankcase with a soft-

face hammer. Tap only on reinforced por-

tions of the crankcase, not on the crankcase

mating surfaces. Work slowly and carefully

and make sure the crankcase halves sepa-

rate evenly.

EAS30390

CHECKING THE CRANKCASE

1. Thoroughly wash the crankcase halves in a

mild solvent.

2. Thoroughly clean all the gasket surfaces and

crankcase mating surfaces.

3. Check:

• Crankcase

Cracks/damage → Replace.

• Oil delivery passages

Obstruction → Blow out with compressed air.

EAS30397

ASSEMBLING THE CRANKCASE

1. Lubricate:

• Crankshaft journal bearing inner surface

(with the recommended lubricant)

2. Apply:

• Sealant

(onto the crankcase mating surfaces)

ECA20880

Do not allow any sealant to come into con-

tact with the oil gallery, crankshaft journal

bearings, or balancer shaft journal bearings.

×8

×3

×2

×6

×2

×6

17

18

23

24

21

20

27

26

15

12

22

25

16

19

8

9

13

7

6

11

10

14

21

4

3

5

Recommended lubricant

Engine oil

Yamaha bond No. 1215

90890-85505

(Three bond No.1215®)

Loading...

Loading...