CONNECTING RODS AND PISTONS

5-80

EAS30750

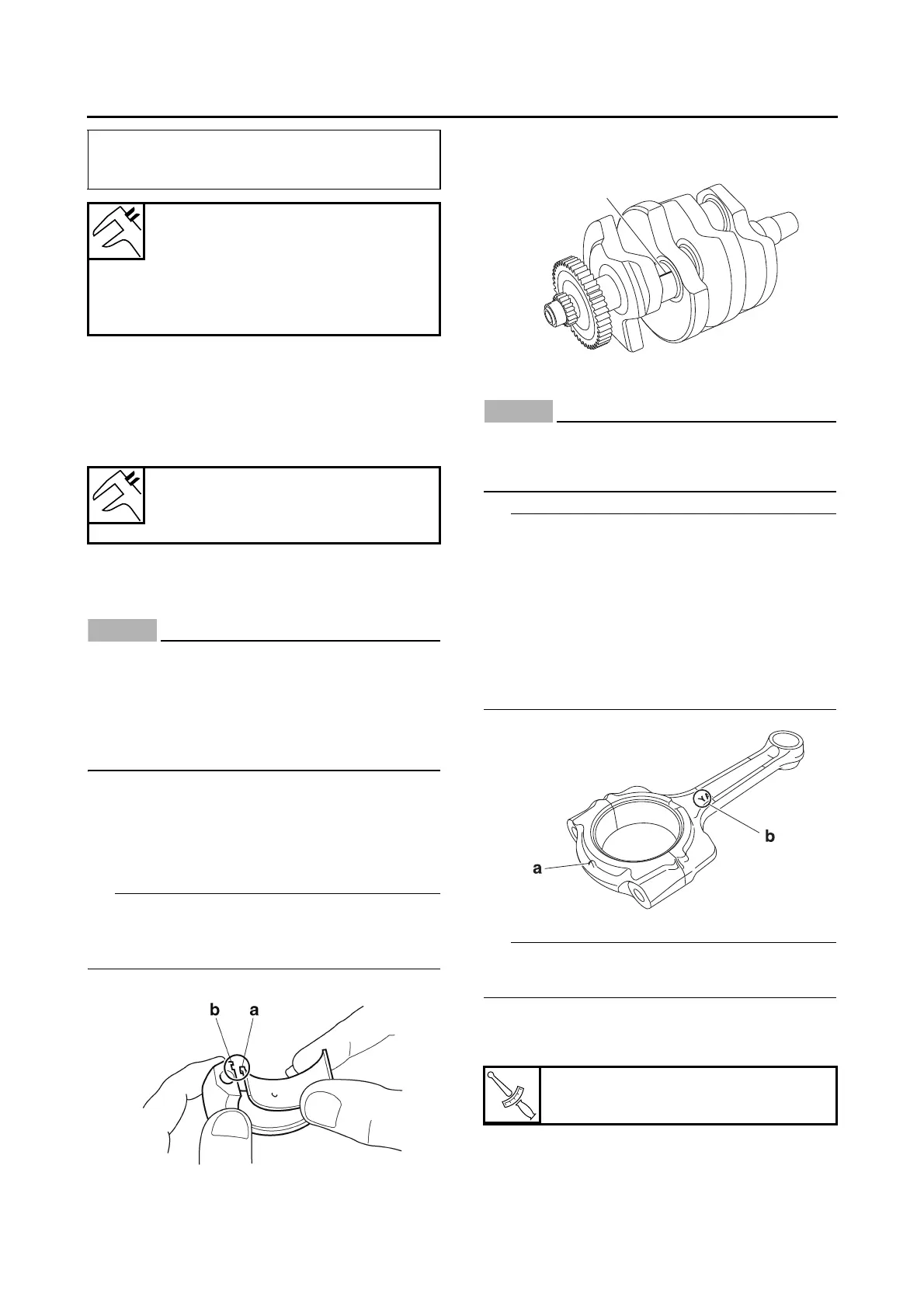

CHECKING THE CONNECTING RODS

1. Measure:

• Crankshaft-pin-to-big-end-bearing clearance

Out of specification → Replace the big end

bearings.

▼▼▼▼ ▼ ▼▼▼▼▼▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼▼▼▼

The following procedure applies to all of the

connecting rods.

ECA13930

Do not interchange the big end bearings and

connecting rods. To obtain the correct

crankshaft-pin-to-big-end-bearing clear-

ance and prevent engine damage, the big

end bearings must be installed in their origi-

nal positions.

a. Clean the big end bearings, crankshaft pins,

and the inside of the connecting rods halves.

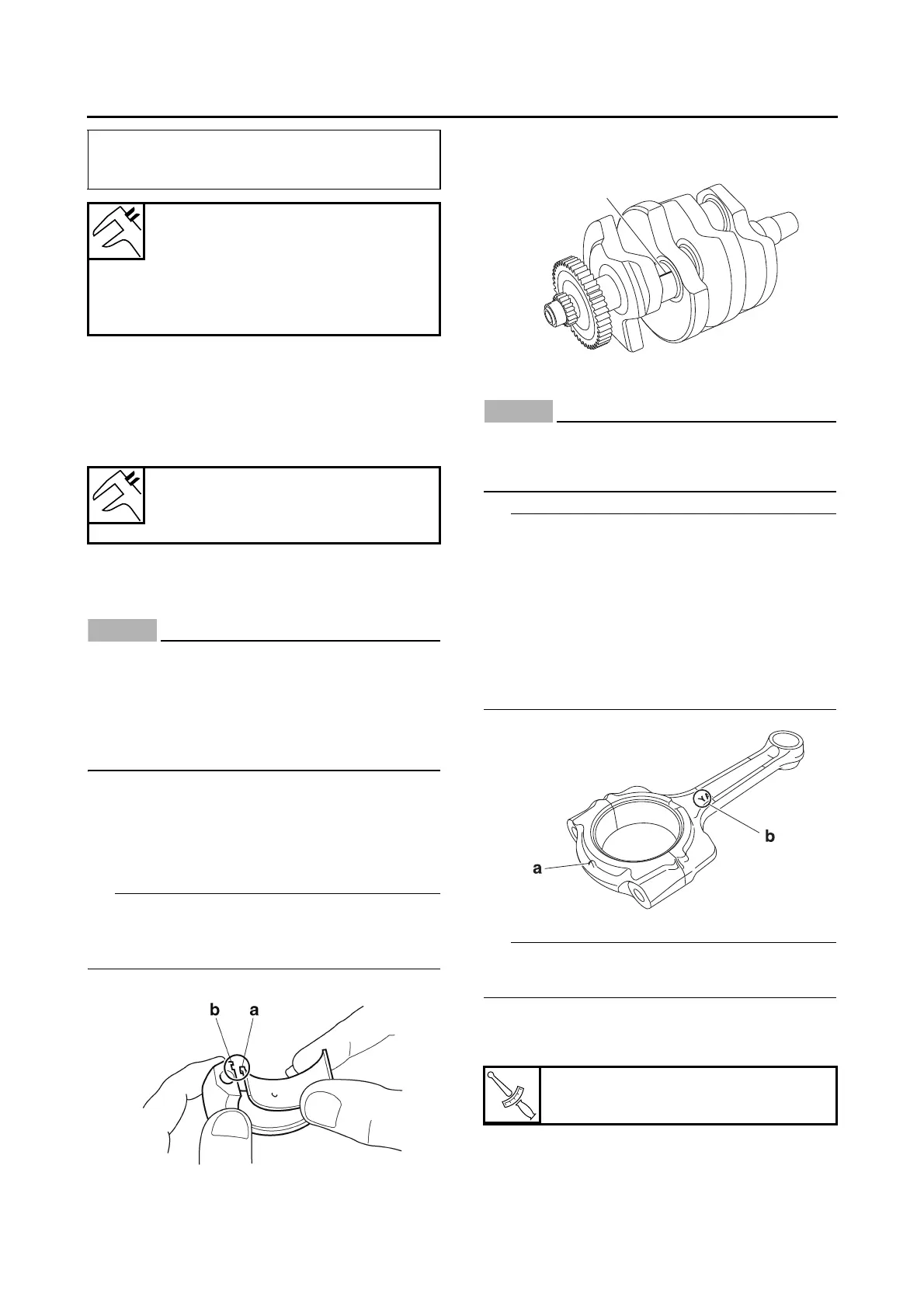

b. Install the big end upper bearing into the con-

necting rod and the big end lower bearing into

the connecting rod cap.

Align the projections “a” on the big end bearings

with the notches “b” in the connecting rod and

connecting rod cap.

c. Put a piece of Plastigauge® “1” on the crank-

shaft pin.

d. Assemble the connecting rod halves.

ECA18390

Tighten the connecting rod bolts using the

plastic-region tightening angle method. Al-

ways install new bolts.

• Clean the connecting rod bolts and lubricate

the bolt threads and seats with molybdenum

disulfide oil.

• Make sure that the projection “a” on the con-

necting rod cap faces the same direction as the

“Y” mark “b” on the connecting rod.

• After installing the big end bearing, assemble

the connecting rod and connecting rod cap

without installing them onto the crankshaft.

Install by carrying out the following procedures in

order to assemble in the most suitable condition.

e. Tighten the connecting rod bolt while check-

ing that the sections shown “a” and “b” are

flush with each other by touching the surface.

Piston-pin-to-piston-pin-bore clearance =

Piston pin bore inside diameter “b” –

Piston pin outside diameter “a”

Piston-pin-to-piston-pin-bore

clearance

0.009–0.025 mm (0.0004–0.0010

in)

Limit

0.075 mm (0.0030 in)

Oil clearance

0.027–0.051 mm (0.0011–0.0020

in)

Connecting rod bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

Loading...

Loading...