—————— Instruction manual ——————

333

Control of the speed reference

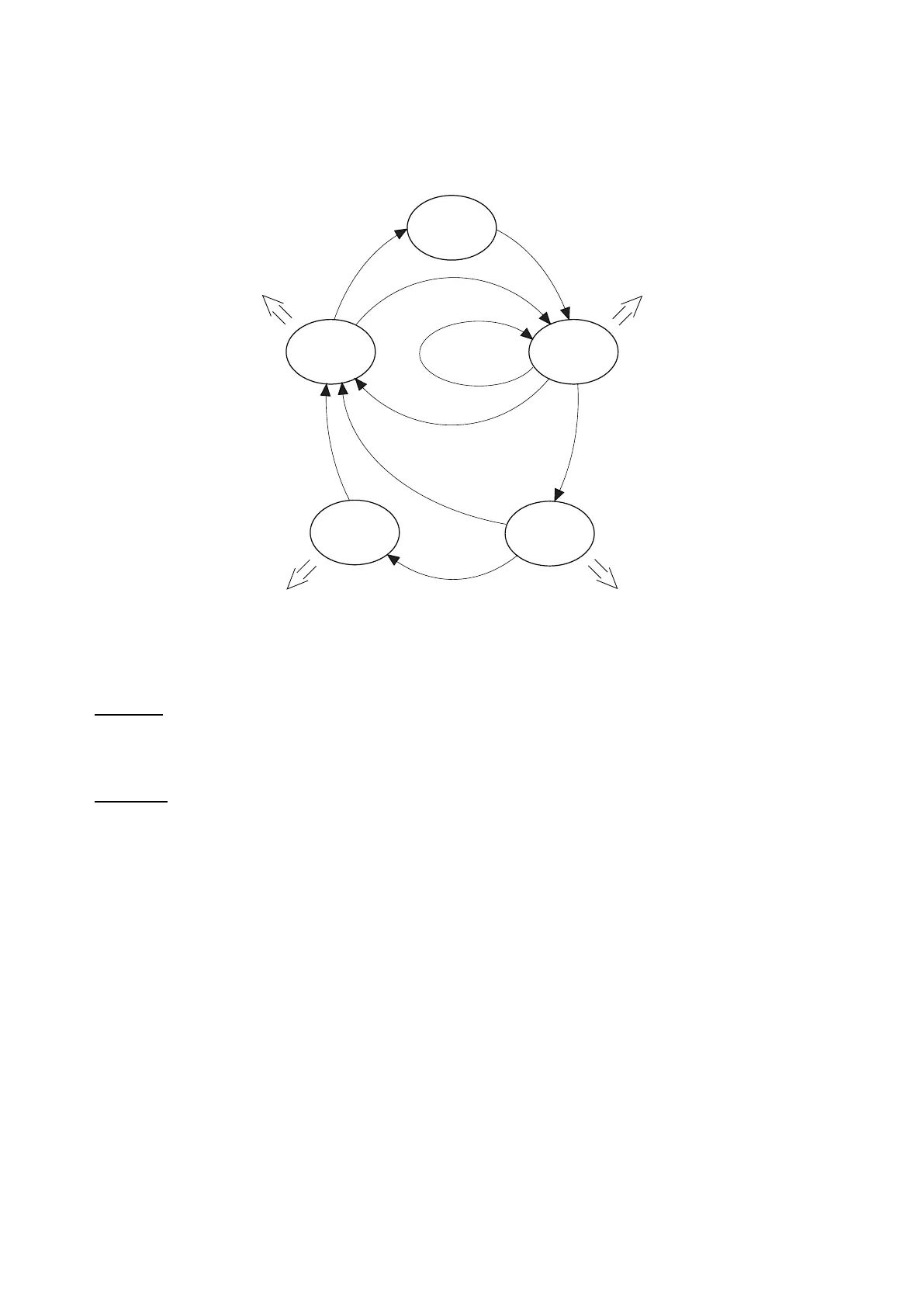

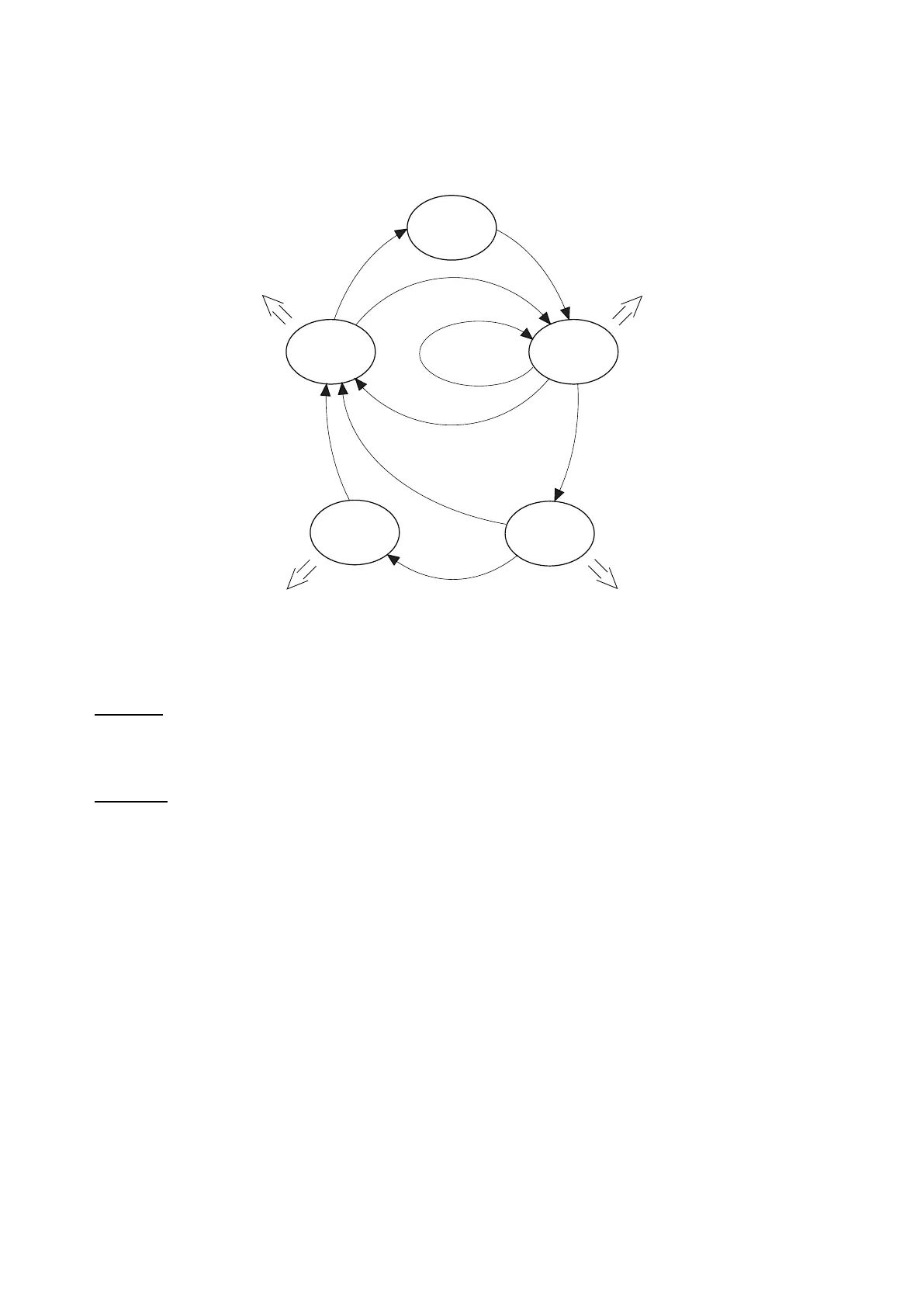

Inordertocalculatethespeedreferenceduringthedifferentfunctioningphasesofthemachine,astatuslogic

hasbeendeveloped.Thestatussequenceandtheoperativenessisdescribedinthegure6.17.3.

Status 1

(default)

Status 2

Status 3

Status 4

Status 5

Start (drive) = 1

Start (drive)=1

Start (drive)=0

Start (drive) = 0

Start (drive)=0

Speed match=1

Speed match=0

Speed 0 thr = 1

Int acc time=0

Int dec time=0

Int offset acc time=Offset acc time

Intwoffset=Woffset

Int acc time=Spd match acc

Int dec time=0

Int offset acc time=0

Intwoffset=0

Int acc time=0

Int dec time=Spd match dec

Int offset acc time=0

Intwoffset=0

Int acc time=0

Int dec time=0

Int offset acc time=0

Intwoffset=Woffset

Figure 6.17.3: Operative sequence of the functioning status

Status 1:

Defaultstatus,thissystemconditionisgivenwhenthedriveisinaStopcondition.Thespeedreferenceiszero.

Status 2:

ThesystemreachesthisstatuswhentheStartcommandisgiven.

Whenthelineisstopped,theinitialphasereferenceW offset isassignedwiththeramptimeOffset acc time.

Whenthelineisstarted,themotorspeedreferencefollowsitsprolewithavaluecorrespondingto:

W reference = ± Line speed x (Minimum diameter ÷ Roll diameter) ± (W gain % + W offset)

thesignof:

± Line speed x (Minumum diameter ÷ Roll diameter)

ispositiveifWind/unwind=winder

isnegativeifWind/unwind=unwinder

thesignof:

± (W gain % + W offset)

isusuallypositive,itcouldbechangedonlyifduringtheaccelerationordecelerationphasesatorqueinver-

sionisrequired.

ThepolarityofW referencewillbefurtherinvertedifWinder side=1

(winding/unwindingdown).

IfduringaStatus1functioningperiodthesystemreceivesaStopcommand(Startdrive=0),theStatus5is

forced.

Loading...

Loading...