SECTION 29 - HYDROSTATIC TRANSMISSION

29-3

Op. 29 100

GENERAL INFORMATION

The hydrostatic system provides a means to transfer

power from the engine to the final drive for the

wheels. It provides infinitely variable speed forward

and reverse and steering of the skid steer.

The hydrostatic pumps receive power from the

engine through a flex plate drive. The pumps transfer

hydraulic power to the motors and then through

gearboxes to the final drives, axles, and wheels.

The hydrostatic pumps are controlled separately

from each other and power each side independently.

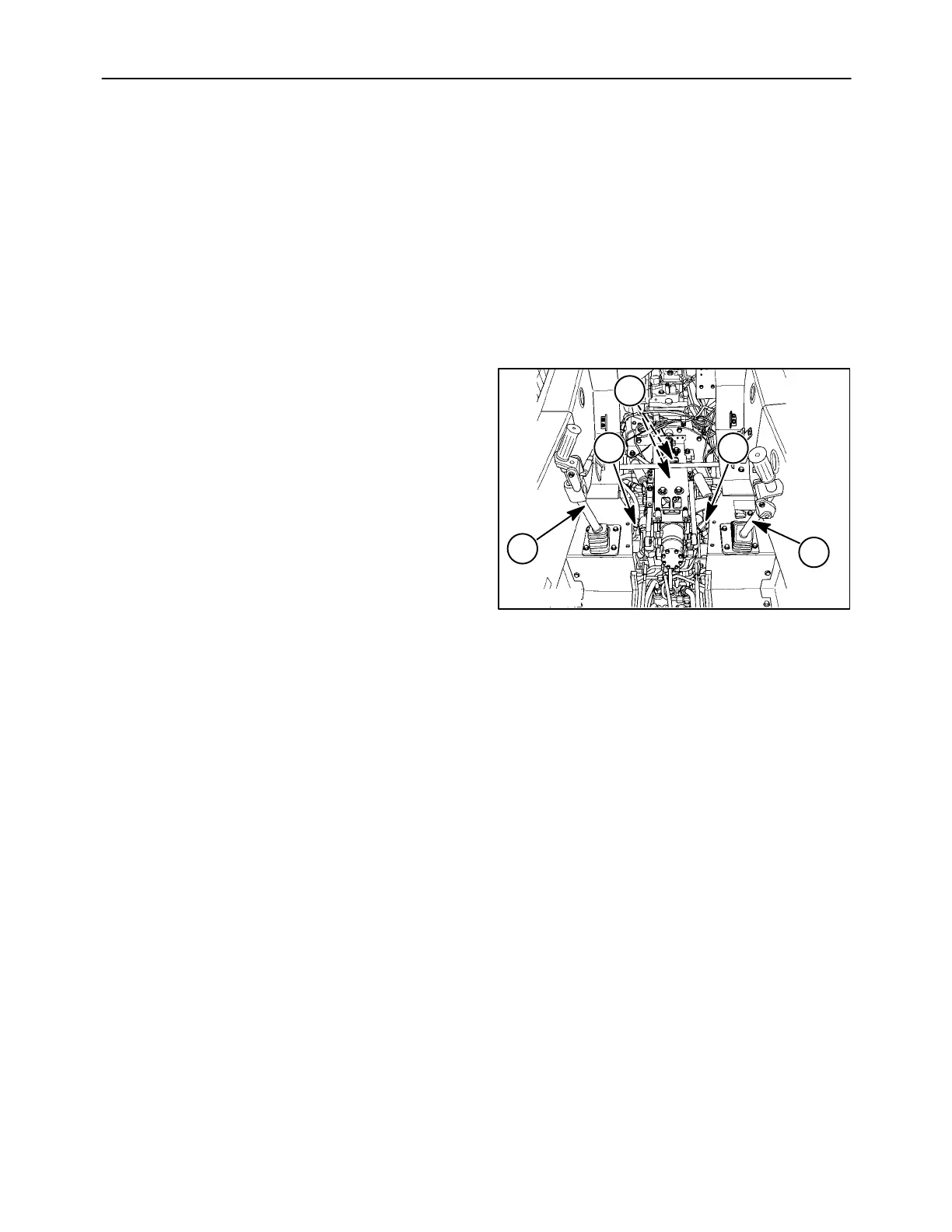

OPERATION

The hydrostatic system is a closed loop fluid power

system that provides smooth transition of power from

the engine to the wheels. The hydrostatic system is

made up of two piston pumps, 1, and two piston

motors, 2. The hydrostatic charge system is a back

pressure valve in the hydraulic system return line

located in the engine compartment. This provides

replenishing oil for the oil that is lost due to leakage

for lubrication and cooling purposes.

Steering is controlled by two hand levers, 3, located

in the operators cab. These hand levers control

direction forward and reverse and amount of oil flow

for speed of the skid steer by rotation of the pump

cam plates in the individual pumps. The further the

control levers are pushed from neutral the greater the

cam plate angle. More oil is pumped to the motors

increasing the wheel speed. The greatest wheel

torque is when the control levers are closer to

neutral. When operating the skid steer, more power

(torque) is available by destroking the control levers,

thus increasing the loader efficiency.

19992568

3

3

2

2

1

1