SECTION 10 - ENGINE

10-63

BACK PLATE/FLYWHEEL HOUSING

Coat the area around the M8 threaded holes with

liquid packing solvent-based sealant and fix the

backplate with bolts.

Backplate tightening torque: 10 - 13 ft. lbs. (14 - 18

N·m)

Housing tightening torque: 18 - 21 ft. lbs. (24 - 28

N·m)

96

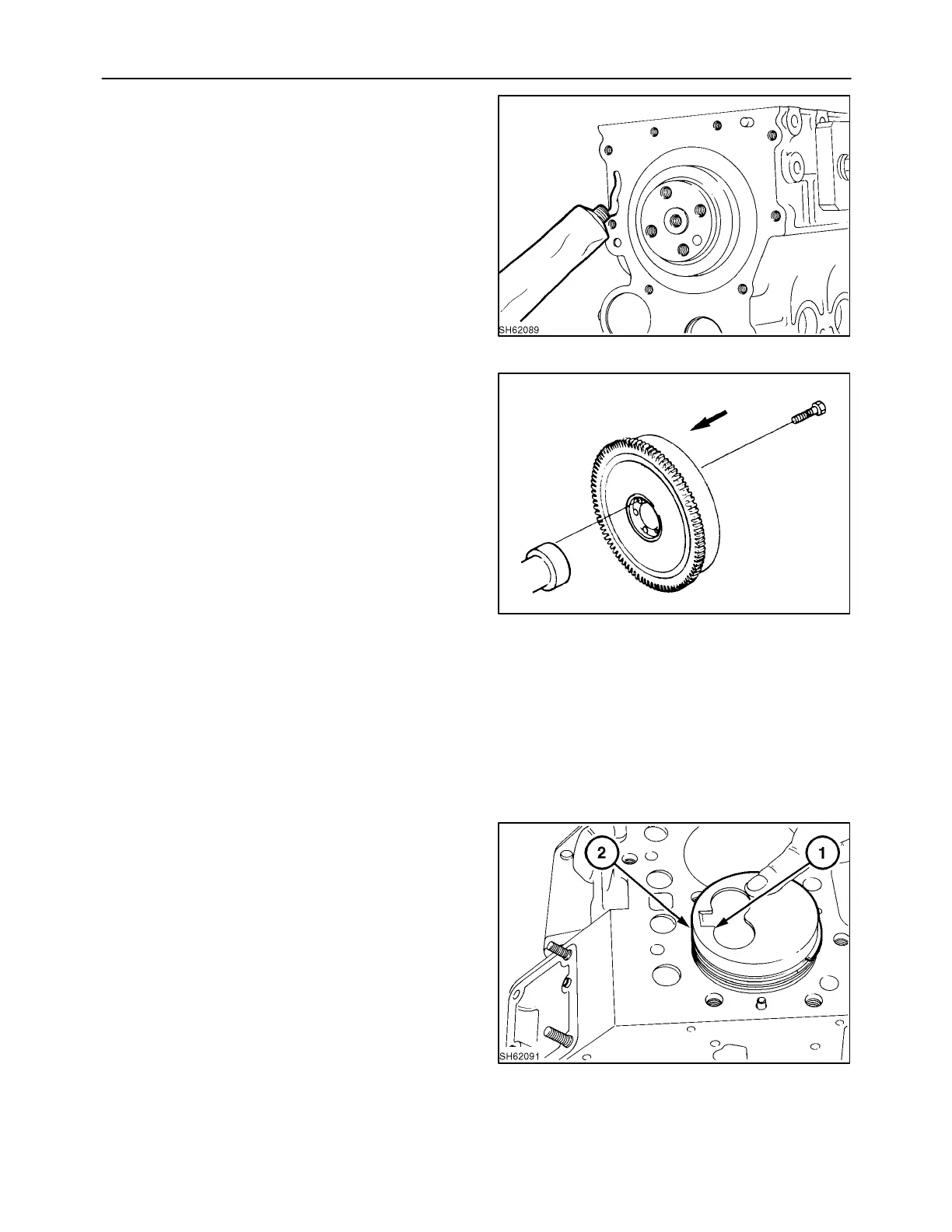

FLYWHEEL

Fit the flywheel. Note the location of the spring pin.

Flywheel tightening torque: 43 - 50 ft. lbs. (58 - 68

N·m)

19992603

97

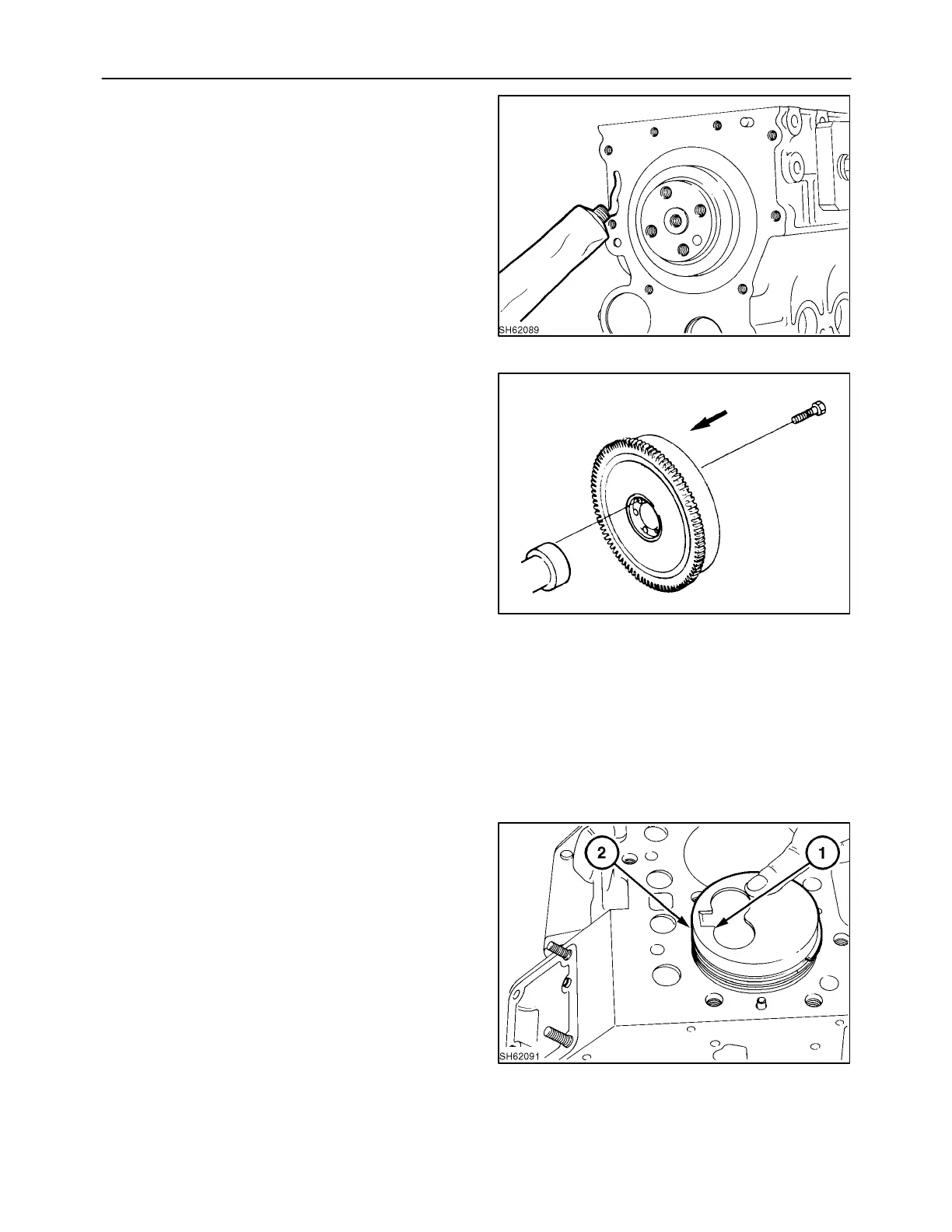

PISTON AND CONNECTING ROD

Coat the bearing face, piston, and piston ring with

clean engine oil.

Slide the piston ring to permit a sufficient amount of

oil to be applied in the groove. Set the piston ring

gaps 90° apart from each other. However, do not

position these gaps toward the piston pin or the right

angle of the pin.

Insert the piston using a ring compressor. Face the

reference mark, 1, on the piston toward the injection

pump side, 2, as indicated. Also face the connecting

rod mark towards the fuel pump side.

NOTE: Install pistons from the front in ascending

order.

Tighten the connecting rod cap to the specified

torque.

Connecting rod tightening torque: 36 - 40 ft. lbs. (49

- 54 N·m)

NOTE: After installation, ensure the crankshaft

moves freely. Ensure the axial play of 0.004 to

0.012 (0.1 mm to 0.3 mm) is provided.

98

Loading...

Loading...