SECTION 10 - ENGINE

10-39

Op. 10 101 55

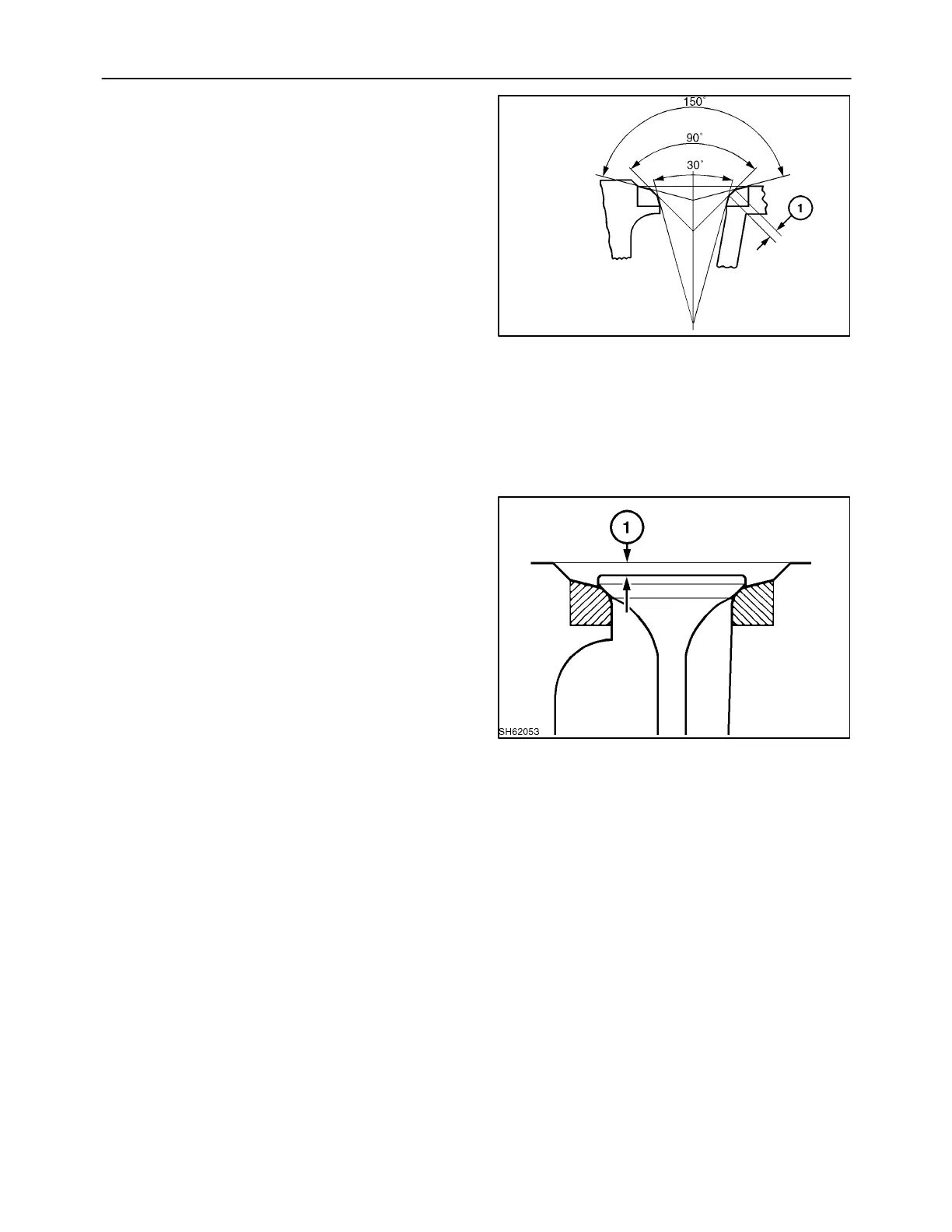

VALVE SEAT

Valve Seat Contact Width

If the contact width at 1 of the valve seat is more than

the allowable width, check the wear condition of the

valve guide first.

Using the seat cutters of 15°, 45°, and 75°, correct

the seat.

Intake

Standard Width: 0.06″ - 0.08″ (1.5 mm - 2.0 mm)

Allowable Limit: 0.098″ max. (2.5 mm)

Exhaust

Standard Width: 0.076″ - 0.085″ (1.94 mm - 2.16

mm)

Allowable Limit: 0.098″ max. (2.5 mm)

SH62052

53

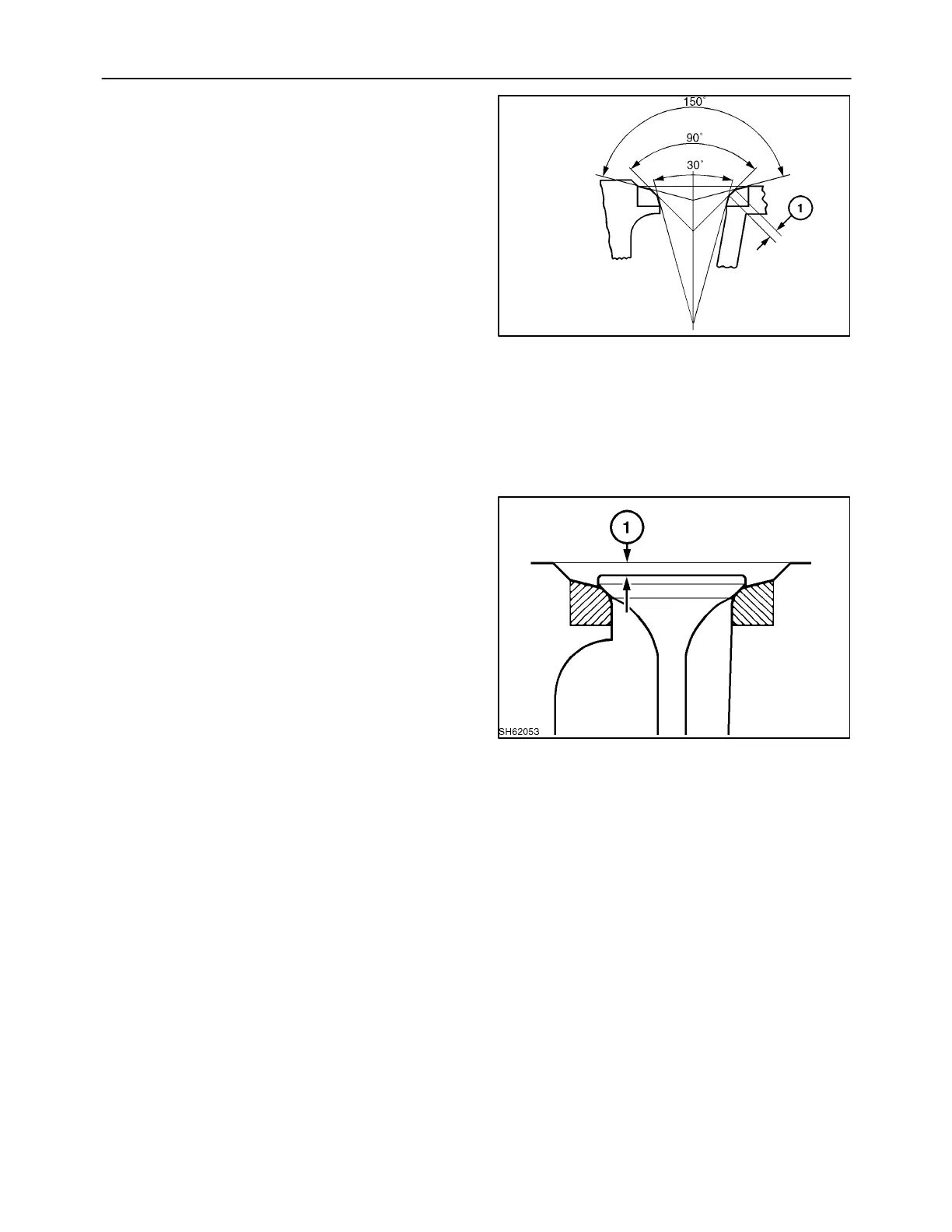

Valve Seat Recess

If the recess depth, 1, is more than the allowable limit,

replace the valve seat (if fitted).

Standard Recess: 0.026″ - 0.037″ (0.65 mm -

0.95 mm)

Allowable Limit: 0.063″ max. (1.6 mm)

Replacement of valve seat insert (where fitted:)

Method 1: Using a gas burner, 1300° F to 1475° F

(700° C to 800° C), heat diagonally across the valve

seat insert. Leave in air for three to five minutes and

remove the valve seat insert by light tapping

(ensuring the head is not damaged).

Method 2: Machine the insert out, taking care not to

damage the head.

Clean up the insert bore and fit a new insert, using a

press 7,200 lbs. - 10,850 lbs. (1,000 kgf - 1,500 kgf)

and a suitable smooth surface tool. To assist the

process, chill the valve seat insert with liquid

nitrogen, etc., or heat the head to between 140° F to

212° F (60° C and 100° C).

54

Loading...

Loading...