SECTION 55 - ELECTRICAL SYSTEM

55-29

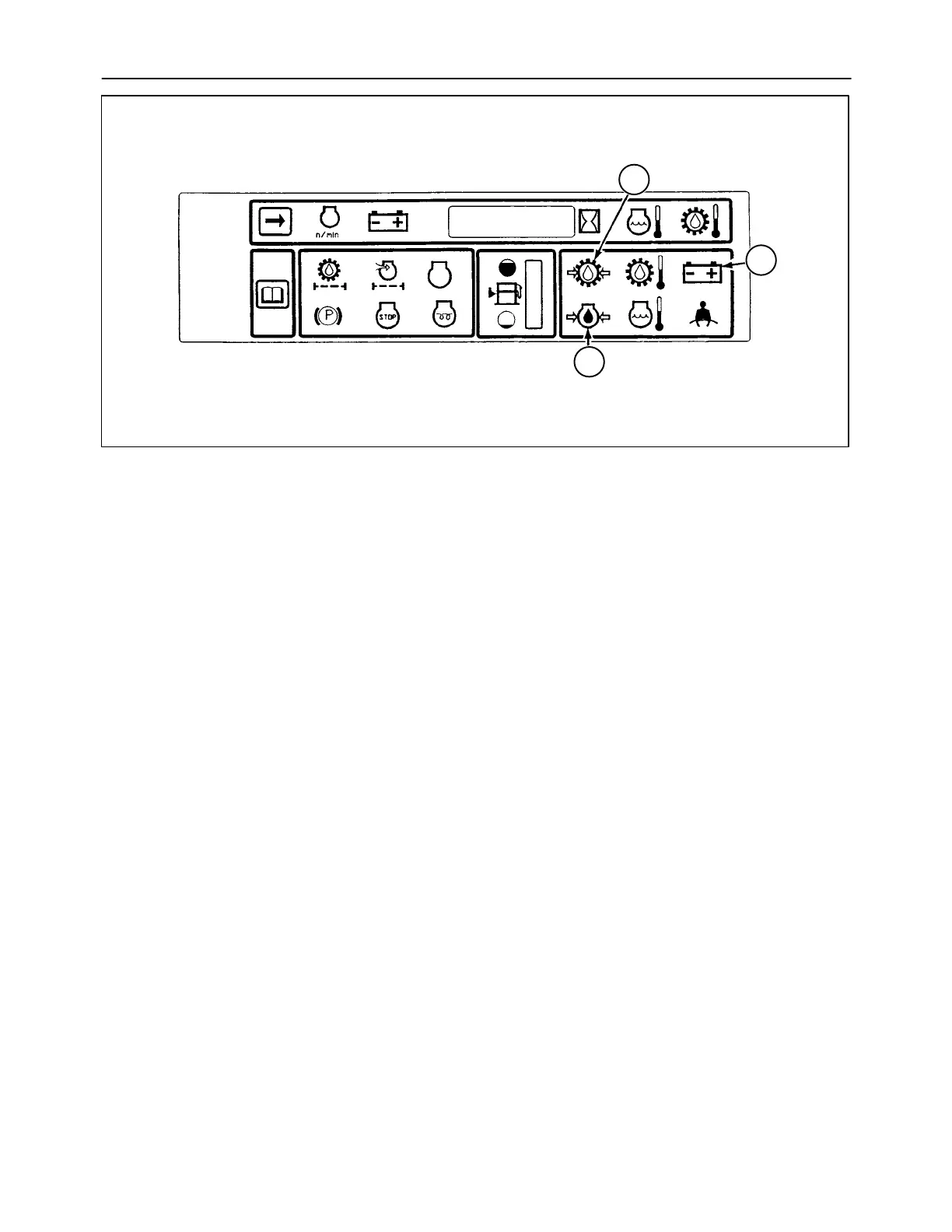

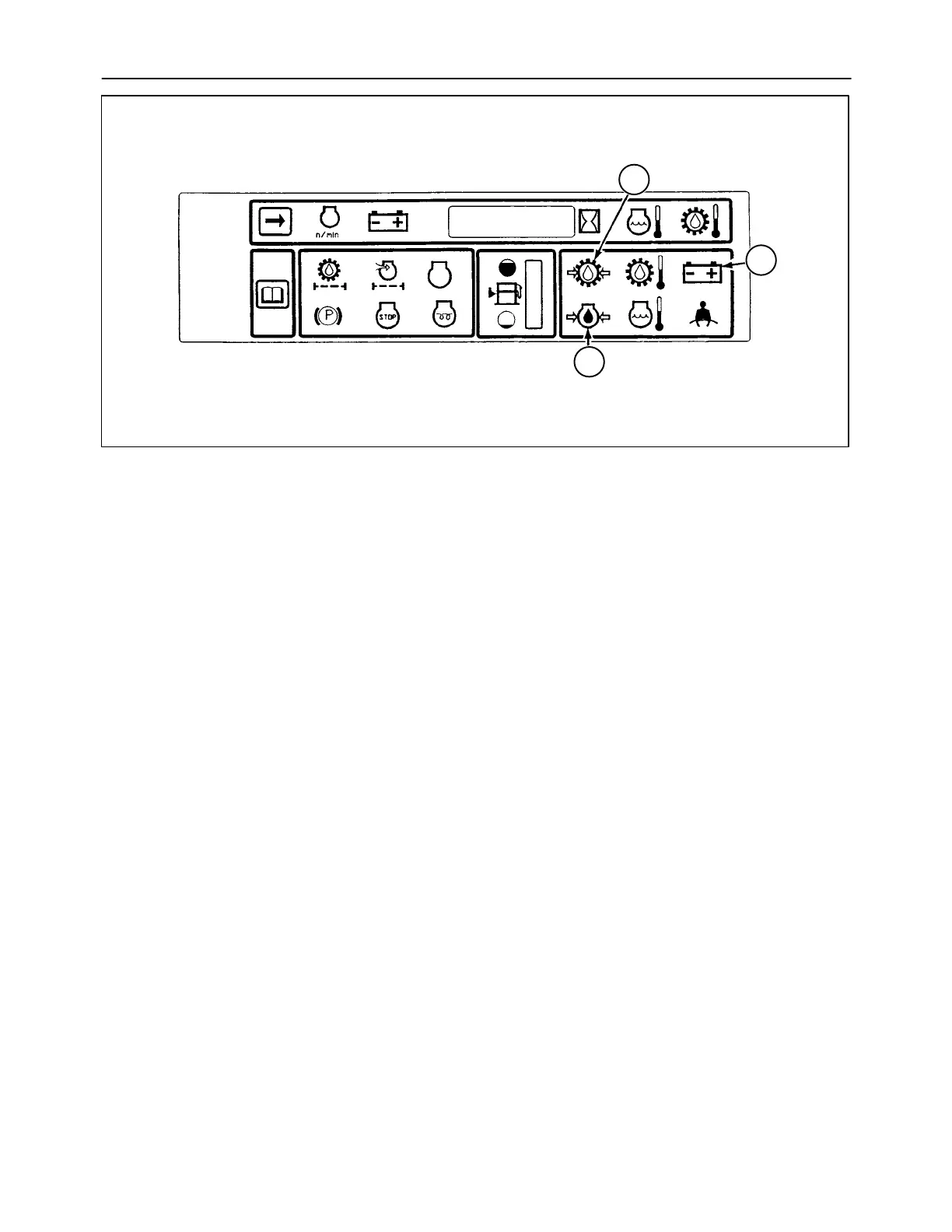

1

2

3

19

If a fault occurs for more than 30 seconds in the

following monitored functions the EIC will signal the

operator with a flashing light, a continuous audible

alarm and will stop the engine after 30 seconds of

operation.

FAULT

1. Engine Oil Pressure

2. Hydrostatic Transmission Charge Pressure

If a fault occurs in one of these functions, the engine

can be restarted and the skid-steer loader moved to

a safe inspection area with the boom resting on the

boom lock pins or on the ground. If the fault still

exists, the EIC will stop the engine after another 30

seconds.

IMPORTANT: Use caution when restarting the

loader because of the possibility of NO

LUBRICATING OILS for the engine and/or the

hydrostatic transmissions. DO NOT restart the

loader more than once or operate the engine at high

engine speeds. Damage to the engine and/or

transmission may occur. Contact your New Holland

dealer for assistance.

BROKEN ALTERNATOR/WATER PUMP

BELT WARNING, 3

If the drive belt breaks the EIC will signal the operator

with the battery symbol light, 3, flashing,

accompanied by an audible alarm.

NOTE: The engine will shut down automatically.

Then immediately turn the ignition key to “OFF”

position to prevent engine overheating or damage.

Loading...

Loading...