SECTION 35 - HYDRAULIC SYSTEM

35-92

8. Liberally oil the piston and place it inside the bar-

rel, being careful not to damage the seals.

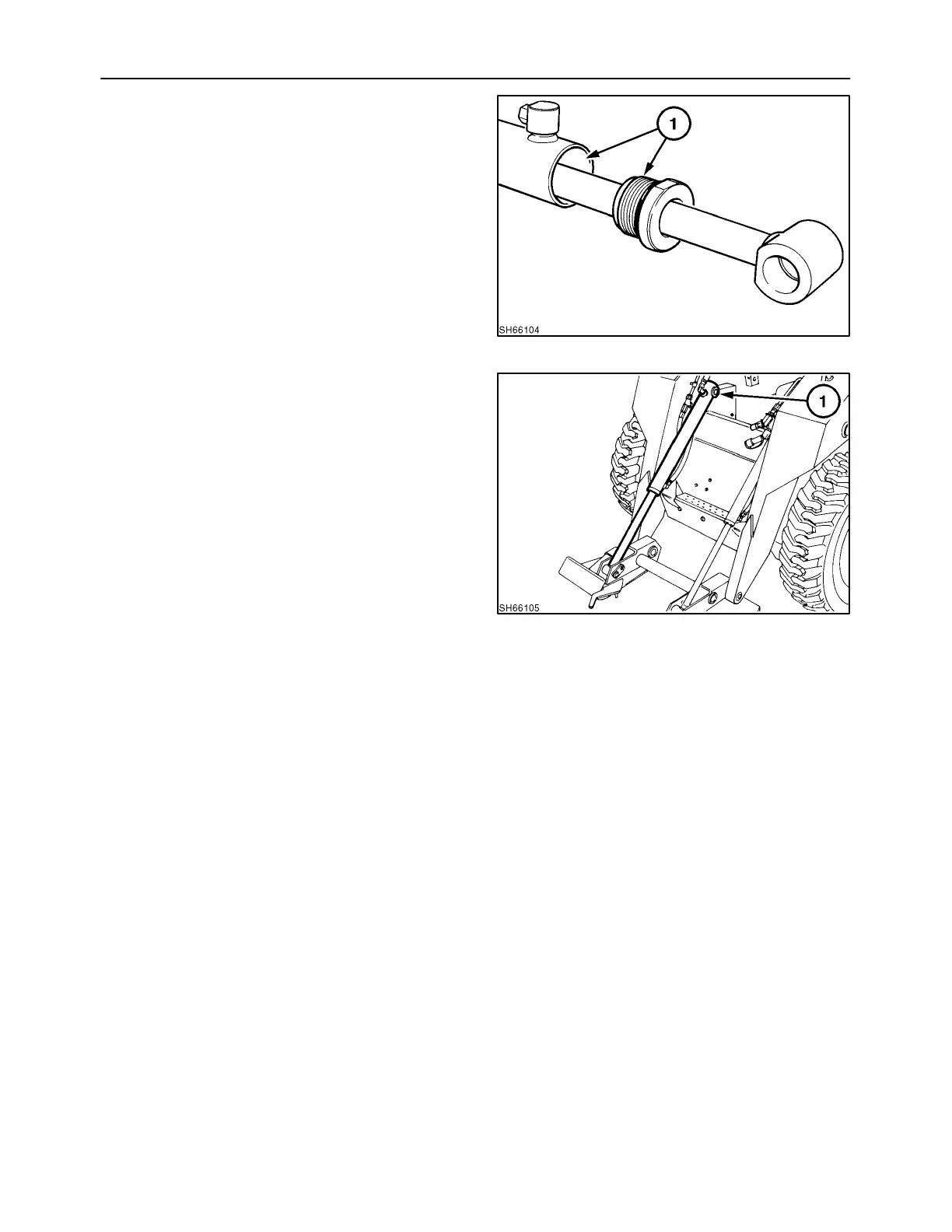

9. Thread the cylinder gland into the barrel, 1, and

torque to 285 N·m (210 ft. lbs.).

167

REINSTALLATION

1. Lubricate the pivot pins with a never seize type

lubricant.

2. Install the cylinder on the loader.

3. Torque the upper pivot pin hardware to 108 N·m

(80 ft. lbs.).

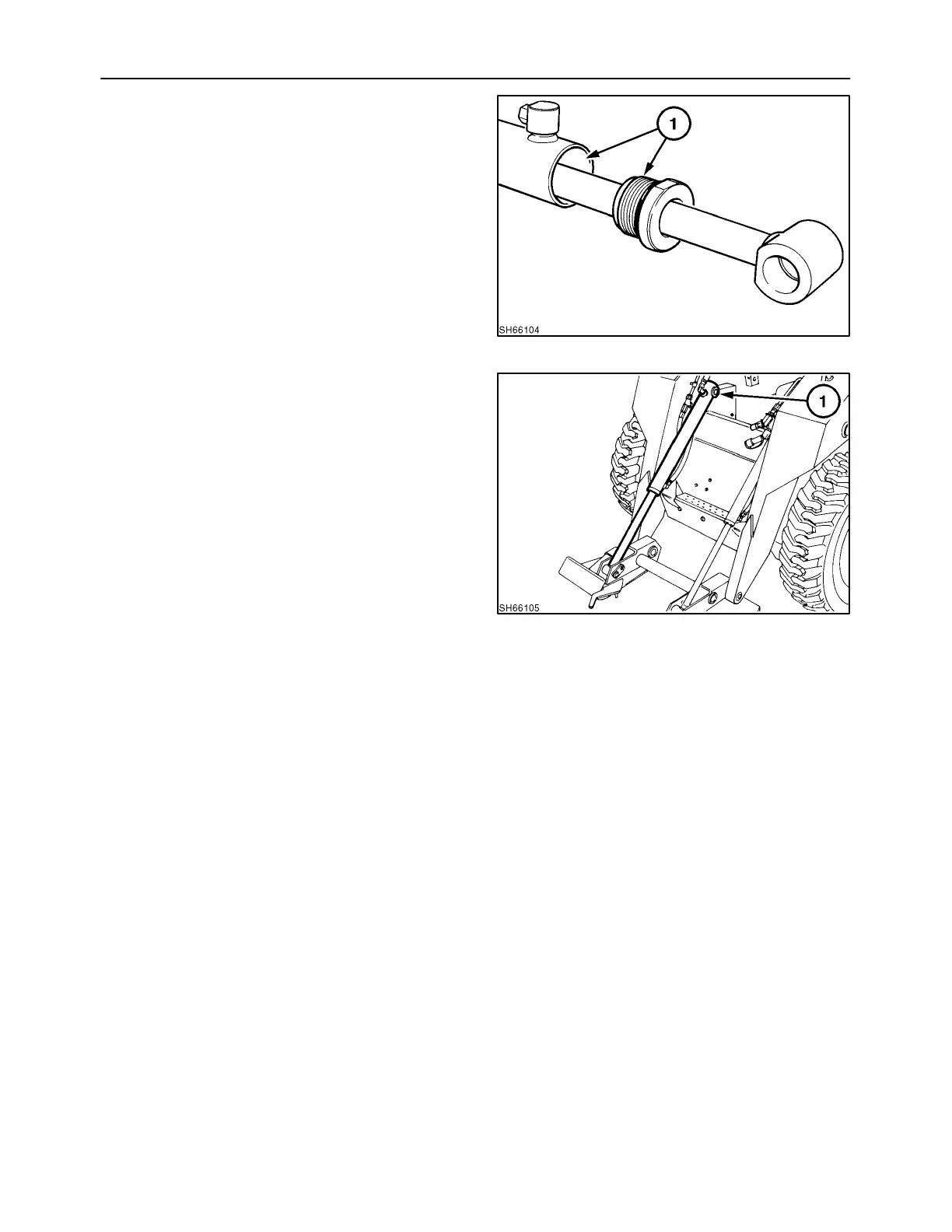

4. With a hammer and using a piece of 2 x 4 hard-

wood to protect the pin, hit the pivot pin and re-

taining hardware at 1, to properly seat the ta-

pered pin and retorque to 108 N·m (80 ft. lbs.).

5. Torque the lower pivot pin hardware to 38 N·m

(28 ft. lbs.).

6. Cycle the boom several times to remove the air

from the system and check the cylinder for leaks.

7. Check the hydraulic oil level and add 10W-30 oil

as required.

168

Loading...

Loading...