SECTION 29 - HYDROSTATIC TRANSMISSION

29-86

12. Adjust the neutral system if required; refer to the

operator’s manual for procedures.

13. Run the engine at 1500 RPM for an additional 30

minutes to filter the oil. Stop the engine and

change the oil filter.

14. Check for oil leaks and repair as required.

15. Reinstall all shields removed for repair.

16. Lower the skid steer to the ground and operate.

191

HYDRAULIC SYSTEM CLEANING

PROCEDURE

After A Hydraulic System Or Transmission

Overhaul

The hydraulic/hydrostatic system must be cleaned if

during repair the cause was from contamination and

the transmissions show wear on the pistons and

shoes, rotating piston blocks, valve plate or cam

plate.

IMPORTANT: Do not use the gear pump and charge

pump to flush the system with solvent. The solvent

will not provide enough lubrication to protect moving

parts inside the transmissions or gear pump.

1. Drain all remaining oil from the hydraulic system.

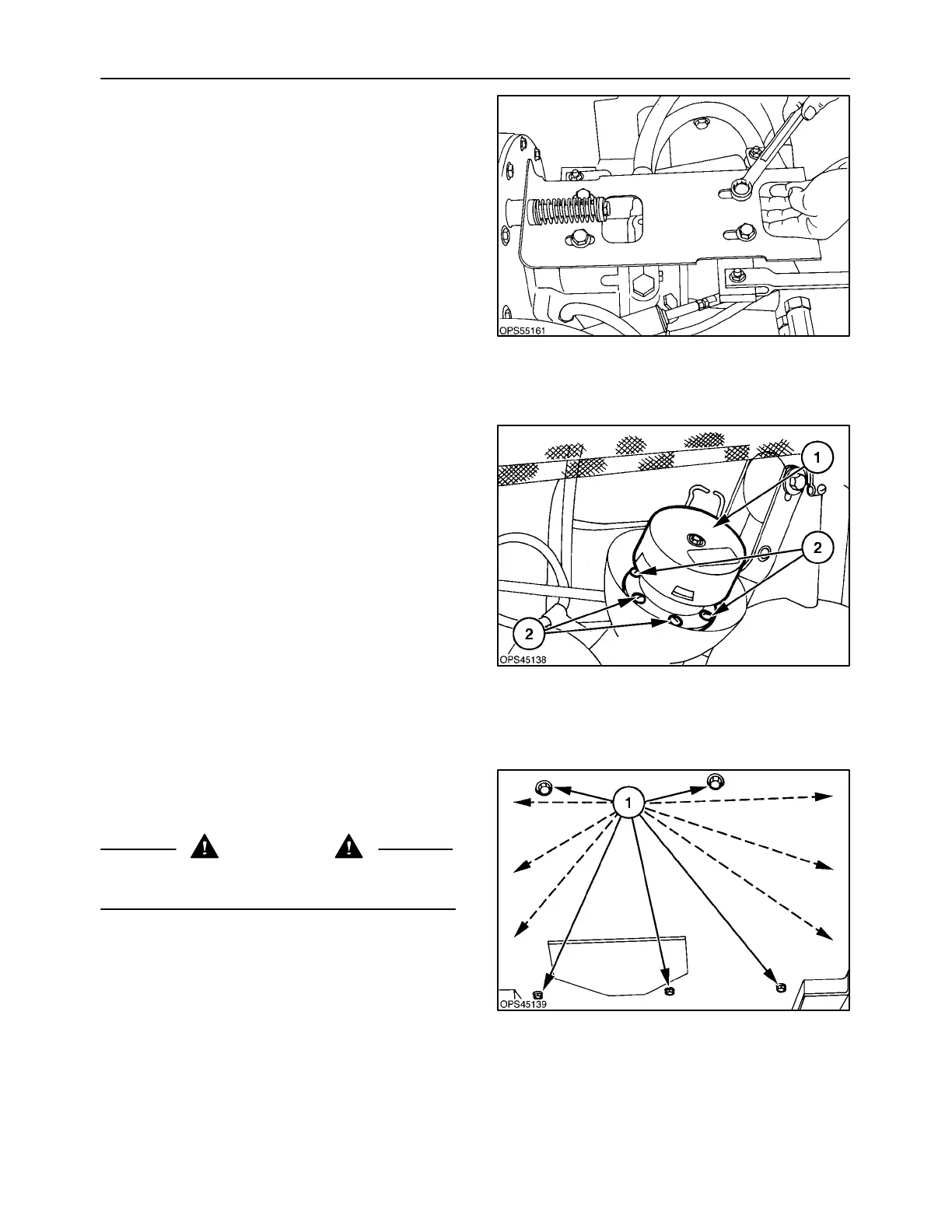

2. Remove fill cap, 1, and screen by removing the

six retaining screws, 2, from the reservoir fill.

Thoroughly clean the screen and fill breather cap

in solvent.

192

3. Drain and flush the hydraulic oil reservoir.

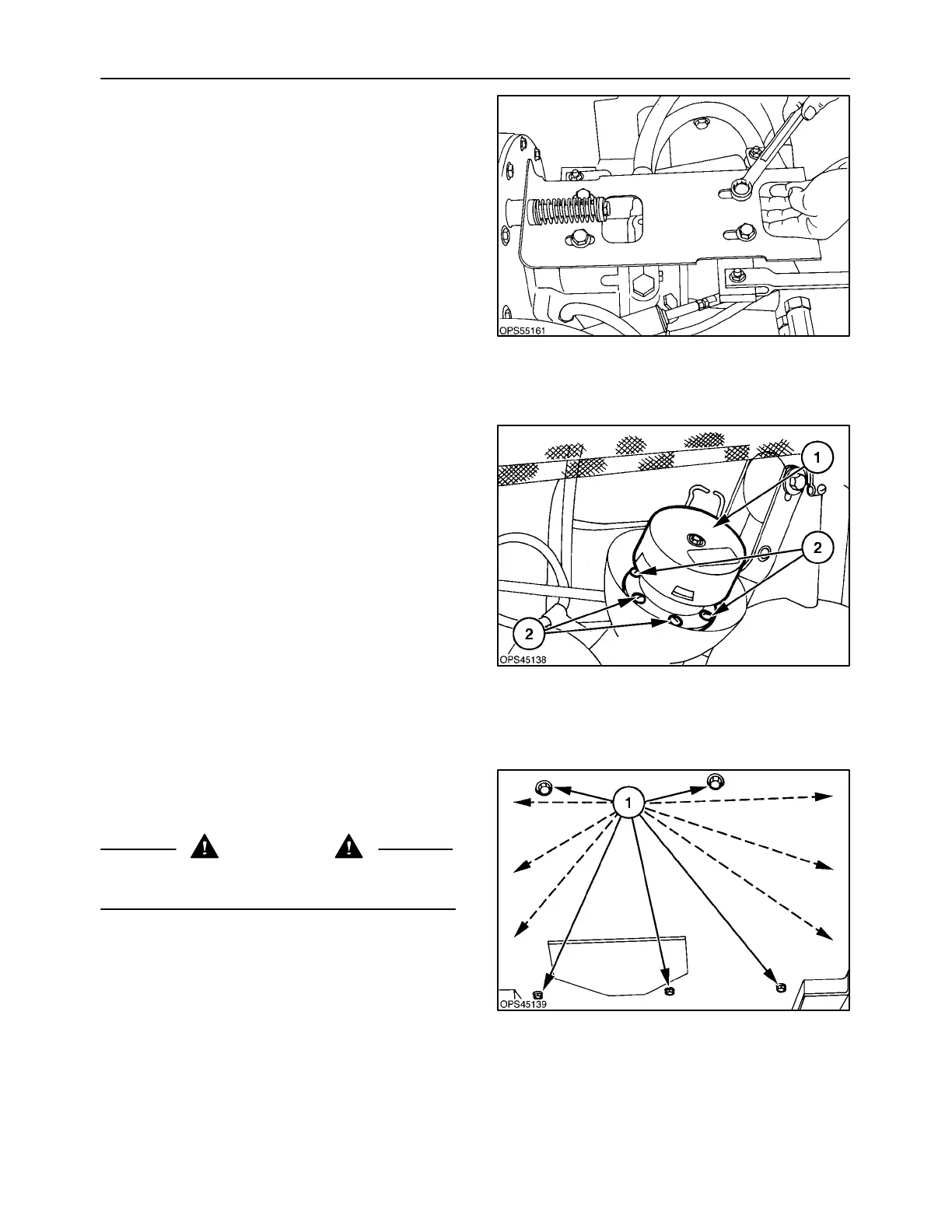

a. Remove the rear engine belly pan hardware,

1, and remove the belly pan.

CAUTION

Use a floor jack to support the belly pan to pre-

vent serious injury.

193

Loading...

Loading...