SECTION 55 - ELECTRICAL SYSTEM

55-152

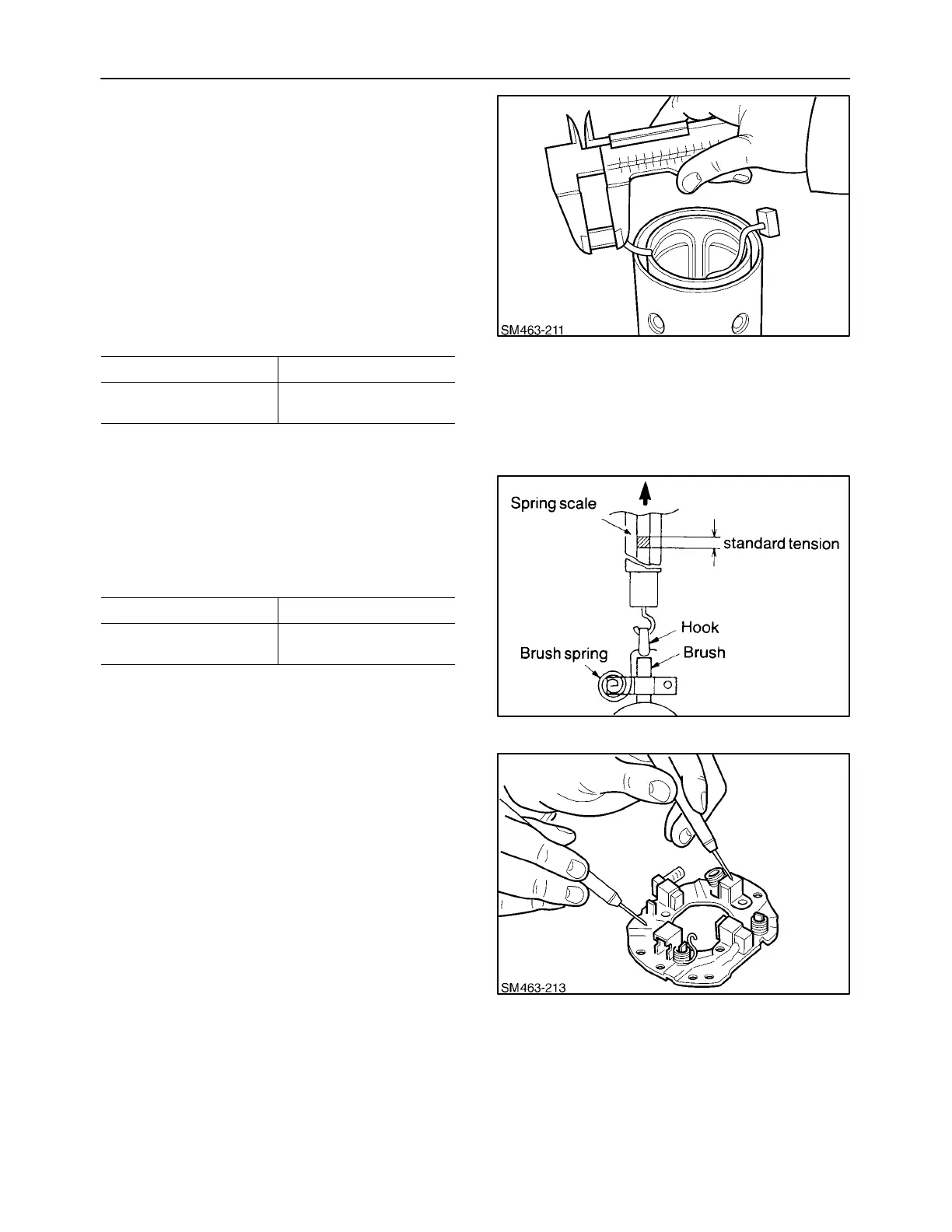

Brushes

Clean brushes and adjacent parts, removing carbon

particles by wiping with a clean cloth.

Check each brush for wear. Replace brushes if they

are worn to the service limit.

The positive brushes are welded to the field

windings. If the positive brushes must be replaced, it

will be necessary to replace the motor housing.

The negative brushes are welded to the brush plate.

If the negative brushes must be replaced, it will be

necessary to replace the brush holder assembly.

Standard Length

Service Limit

15 mm

(0.59″)

9 mm

(0.35″)

222

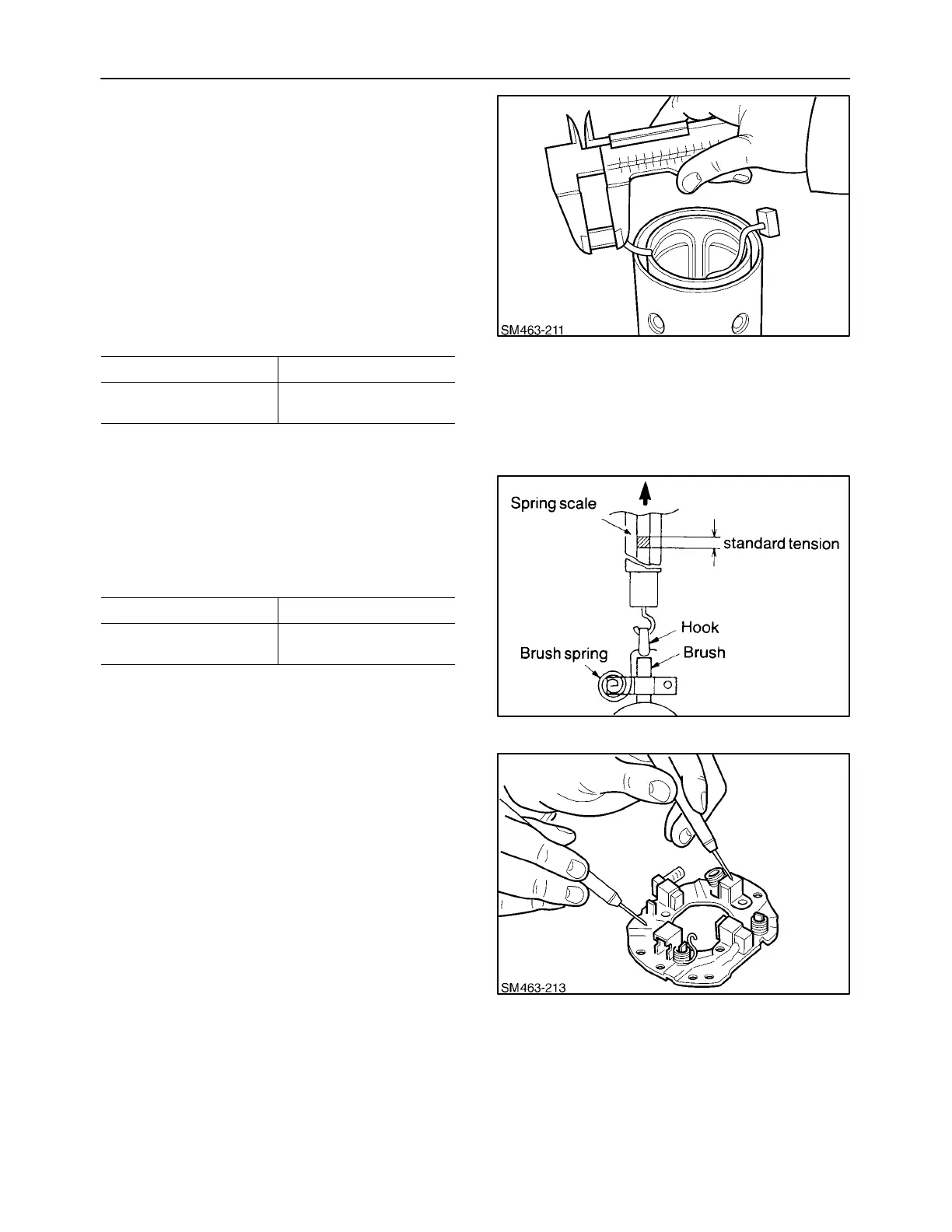

Move each brush in the holder to be sure that it is

capable of sliding smoothly.

Check brush spring tension. Replace the brush

holder assembly if the tension is not within specified

limits.

Standard Tension

Service Limit

2.7 - 3.6 kg

(5.9 - 7.8 lbs)

2.2 kg

(4.7 lbs)

5.9 lbs.

7.8 lbs.

223

Check the brush holder assembly for short to ground.

Touch one probe of a continuity tester to the plate and

the other to each of the insulated holders. Replace

the brush holder assembly if any continuity is noted.

224

Loading...

Loading...