SECTION 10 - ENGINE

10-48

Thrust Clearance

Check the thrust washer for wear, poor contact,

burning, or other defects. Defective washers must be

replaced.

Standard Thickness: 0.116″ - 0.118″ (2.95 mm -

3.0 mm)

Allowable Limit: 0.11″ (2.8 mm)

Reassembly

Reassemble the bearing holder, center bearing, and

thrust washer as follows:

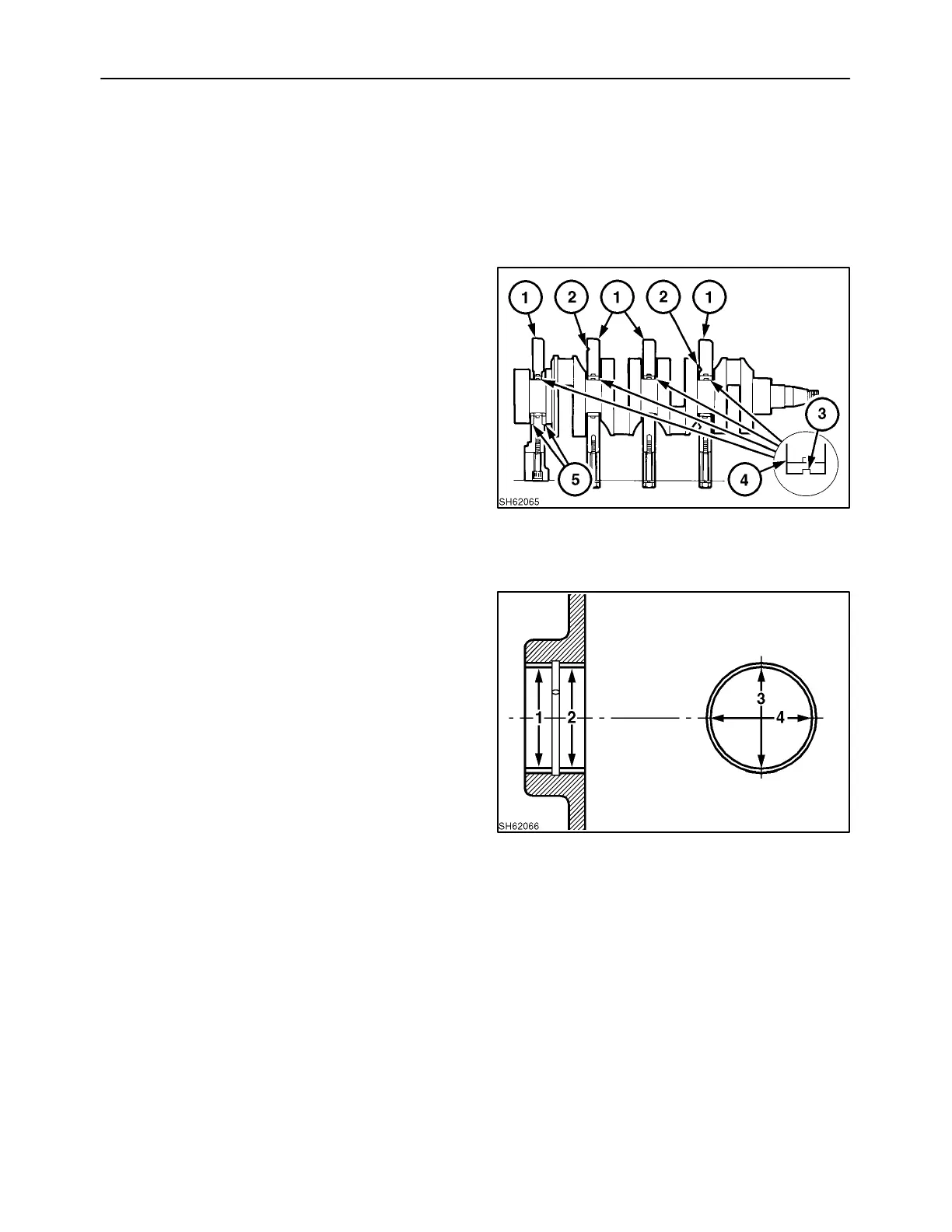

1. Face the chamfered part, 1, of the bearing holder

toward the front. Install the bearing holder which

has a notch, 2. Install the bearing holder on which

the thrust washer is to be mounted at the flywheel

side.

2. Install the thrust washer, 5. Face its oil groove

toward the thrust face of the crankshaft.

Tightening torque of the bearing holder: 36 - 40

ft. lbs. (49 - 54 N·m).

3. Set the bearing with the oil groove, 3, to the upper

part, 4, while setting the bearing without the

groove to the lower part.

66

CRANKSHAFT BEARING (BUSHING)

Inspection

Check the bearing (bushing) for peeling, melting,

seizure, or poor contact. If found to be defective,

replace.

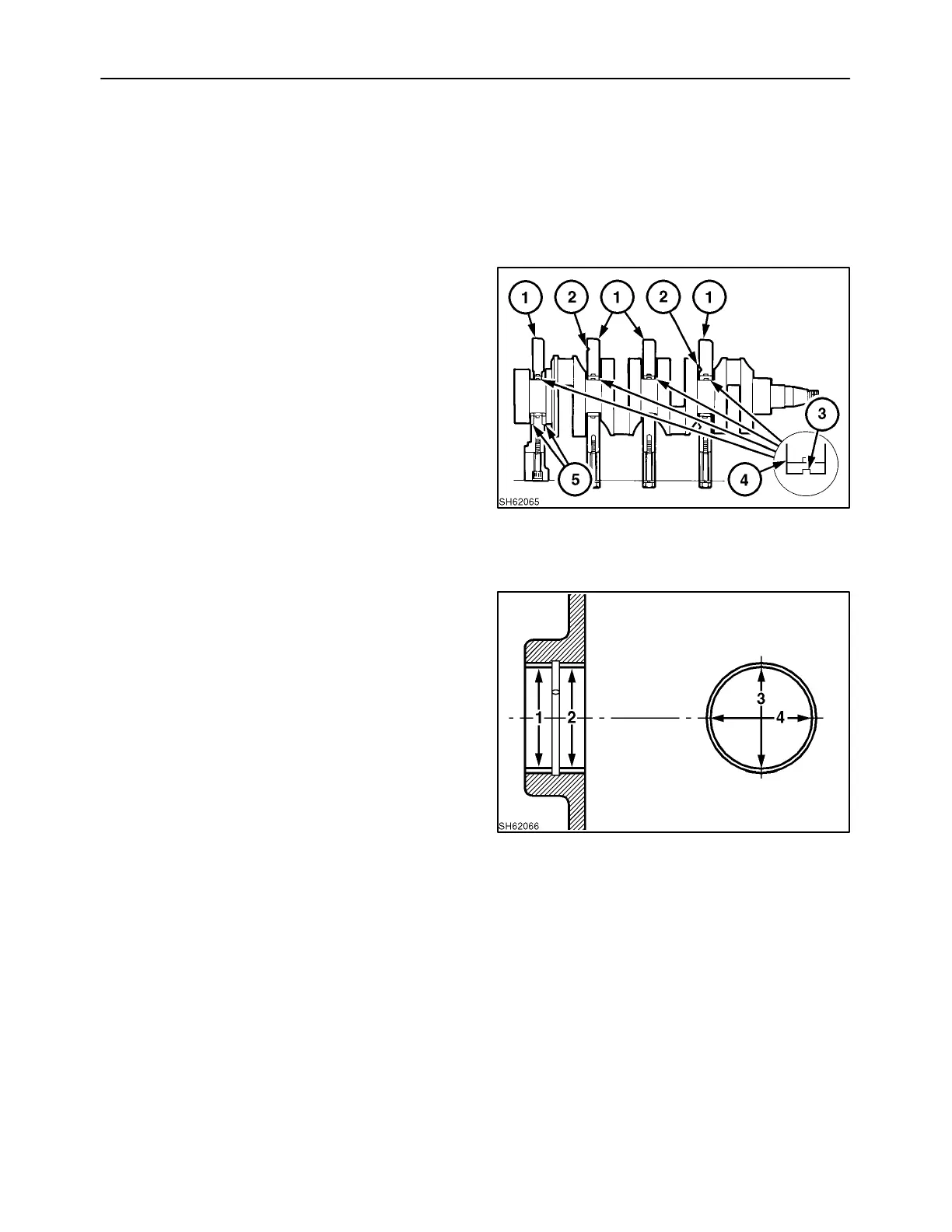

Using a cylinder gauge and micrometer, measure the

oil clearance between the bearing (bushing) and the

crankshaft journal.

Measure the inside diameters at positions 1 and 2. At

each position, measure in both directions 3 and 4.

The oil clearance can be obtained by subtracting this

value from the maximum crankshaft journal

diameter.

67

Loading...

Loading...