SECTION 35 - HYDRAULIC SYSTEM

35-31

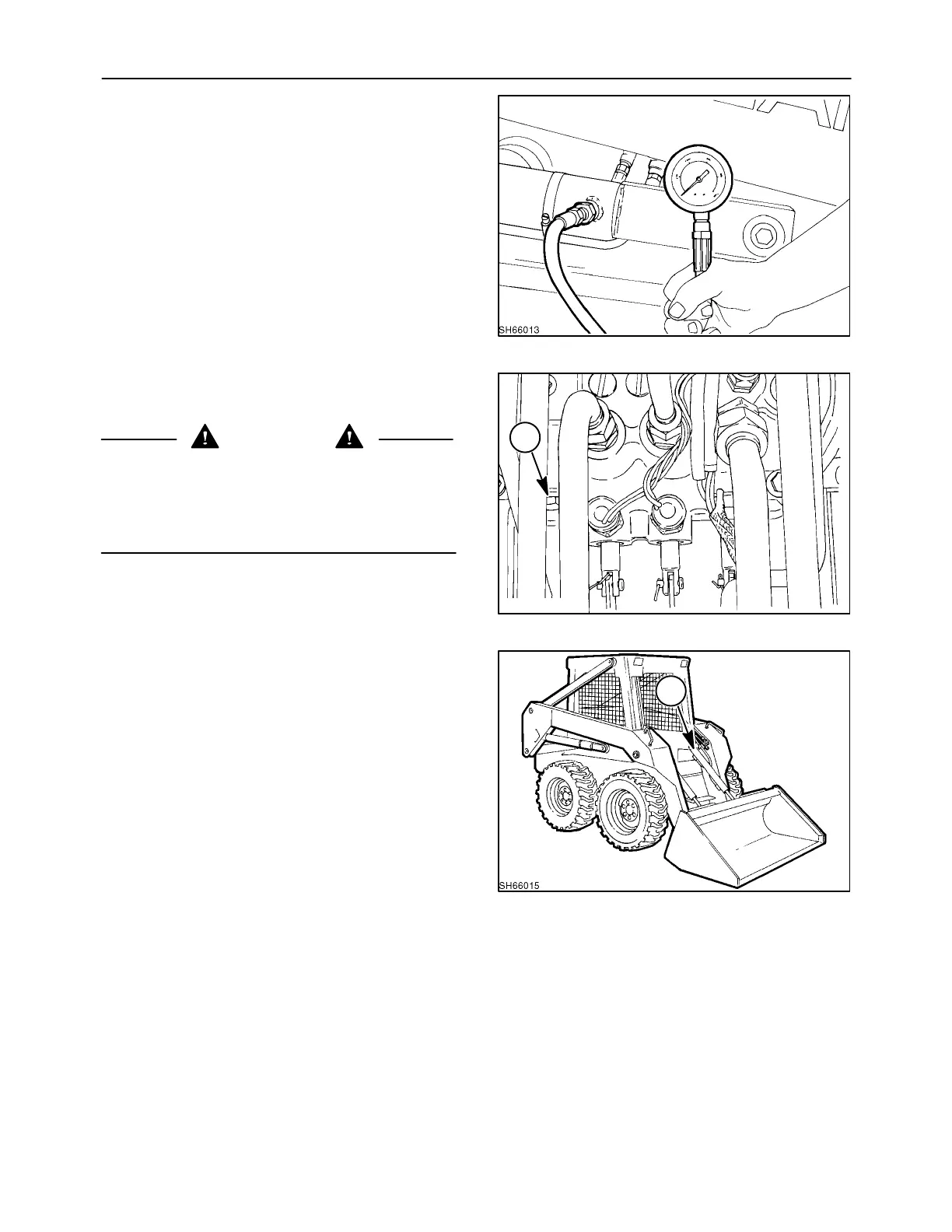

3. Install the pressure test gauge in the boom cylin-

der at 1.

4. Start the engine and run it at full throttle

(3070 - 3150 RPM) to bring the hydraulic oil to

operating temperature.

5. Operate the boom control to raise the boom to

the fully raised position until the system by-

passes and take a pressure reading. Lower the

boom down to the boom lockpins and relieve

pressure in the system.

6. The pressure should be from 177 - 190 bar (2600

- 2800 PSI) when the hydraulic oil is at operating

temperature.

19

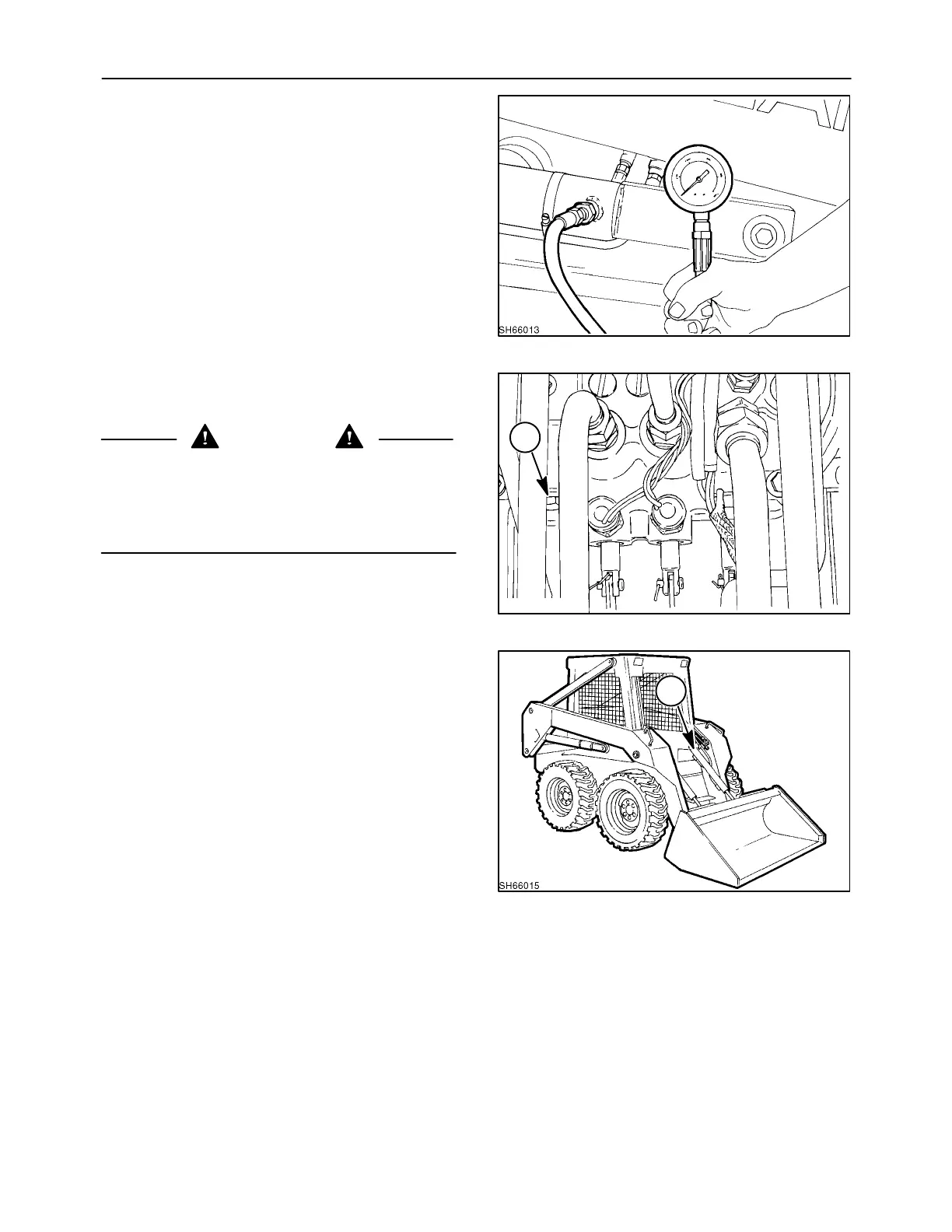

7. The relief valve is a cartridge type and is not ad-

justable. Replace the relief valve cartridge, 1, if

the pressure is not within specifications.

CAUTION

Do not attempt to change the pressure setting or

alter the pressure to a higher setting as the

hydraulic components, hoses, tubes, and

cylinders may be damaged and could cause

injury.

1

19997742

20

CHECKING MAIN SYSTEM PRESSURE AT

BUCKET CYLINDERS, 1

Fittings and gauge required:

1. 238 bar (3500 PSI) gauge (minimum)

2. 3/4″ - 16 UNF O ring fitting

Test Procedure

1. Lower the boom and attachment to the ground.

2. Stop the engine, turn the ignition key to the run

position and operate the boom and bucket con-

trol pedals to relieve pressure in the cylinders.

Turn off the key.

1

21

Loading...

Loading...