SECTION 29 - HYDROSTATIC TRANSMISSION

29-70

REASSEMBLY

IMPORTANT: Due to close tolerances and finish of

motor internal surfaces, it is important to maintain

absolute cleanliness during inspection and

reassembly or damage to the components may

occur.

Be sure all parts are clean and air-dried before

reassembly. Prior to assembling the motor, dip all

parts in the oil, SH/CG4 10W-30, that will be used in

the hydraulic reservoir. This motor must be shimmed

during reassembly. The shim kit gauge block used to

determine the shim pack is included in the seal kit for

the motor assembly.

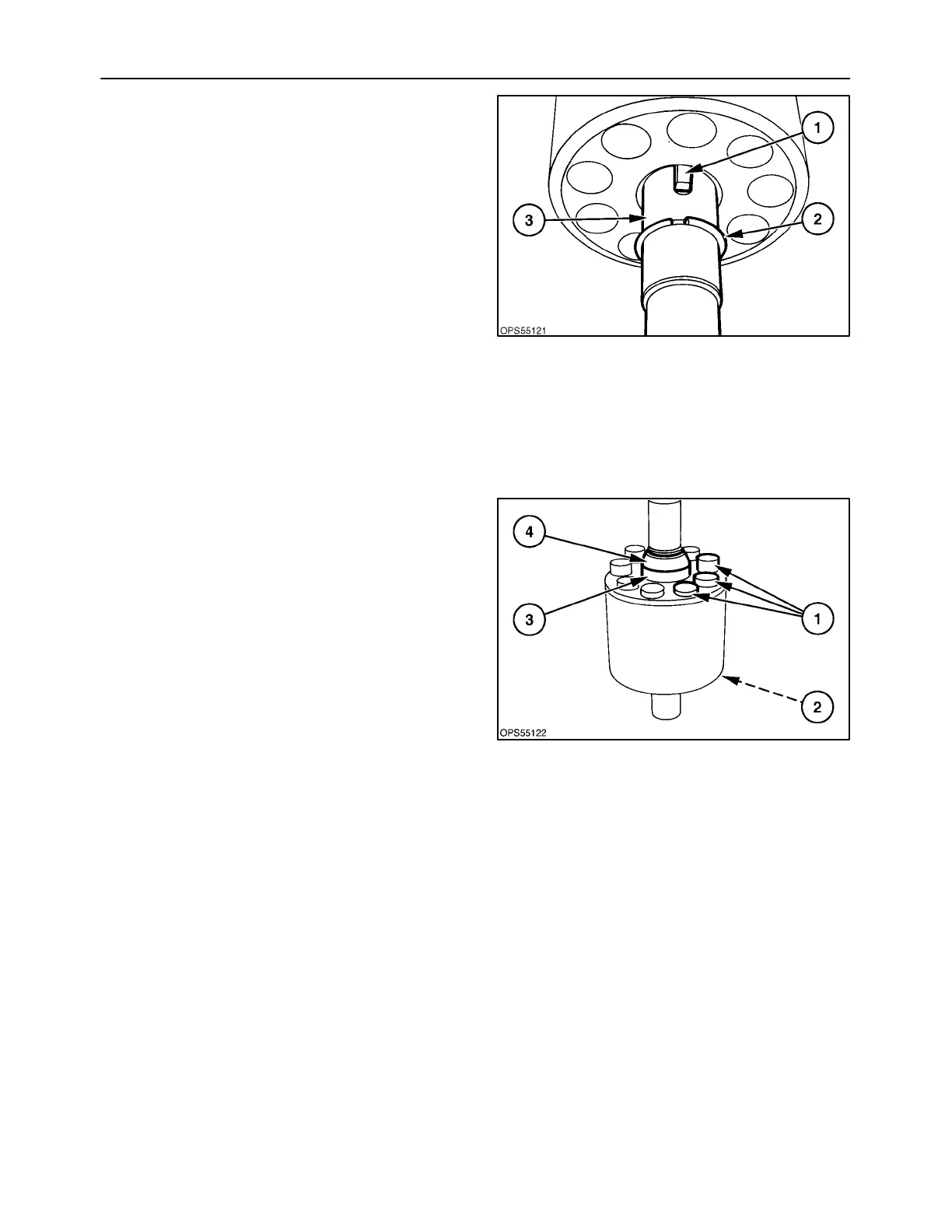

1. Install the key, 1, in the shaft and the round

retaining ring, 2, in the groove.

Slide the piston block on the shaft with the 45°

chamfer, 3, in the inside diameter of the piston

block toward the round retaining ring, 2, on the

shaft.

149

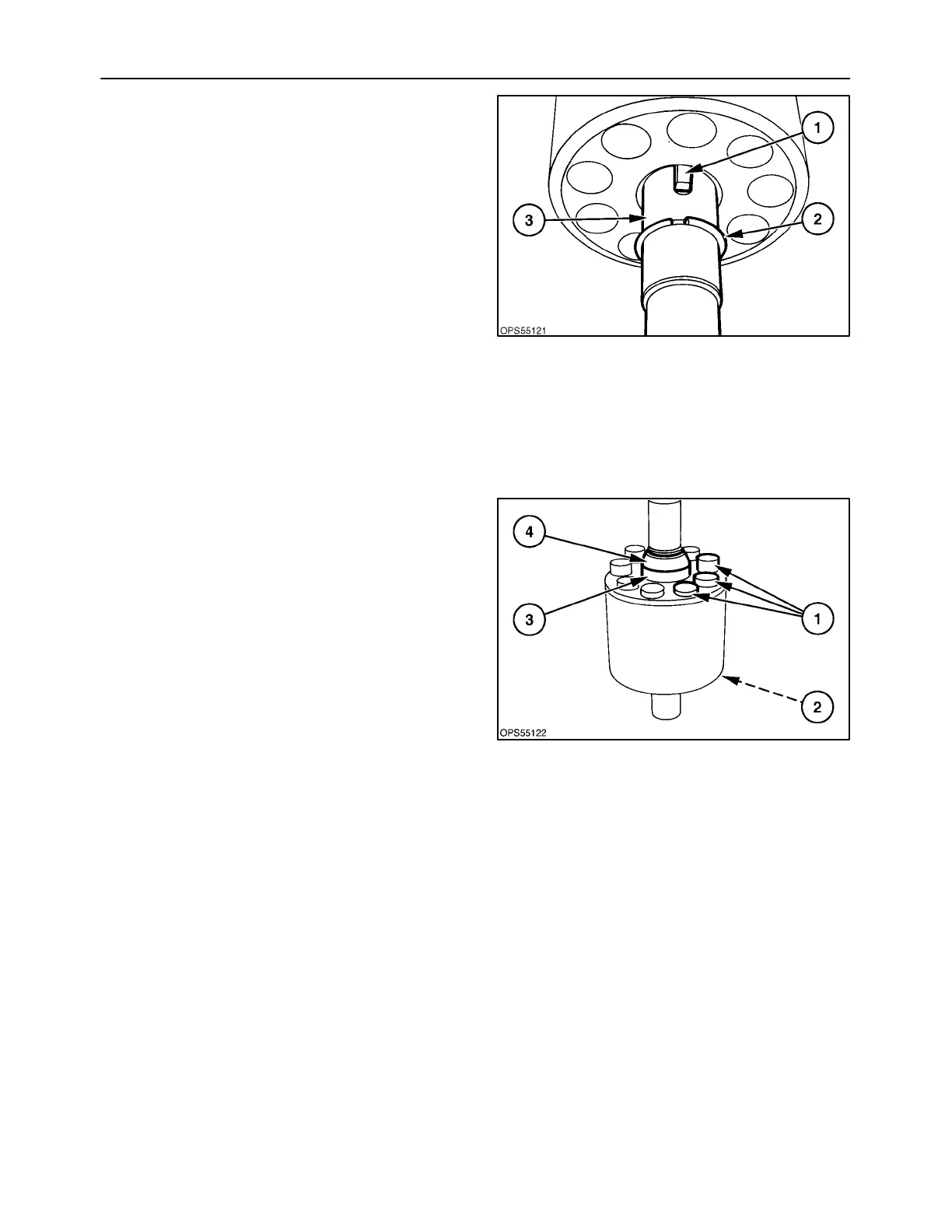

2. Lubricate the solid pistons, 1, with system oil and

install them in the piston block bores from the

tapered end of the block, 2, with the tapered ends

facing outward. Be sure each piston moves freely

in its bore. It is suggested that the assembly be

held with one hand, as shown, so the pistons do

not fall completely through the block.

IMPORTANT: Do not damage the burr around the

piston holes in the block.

3. Slide spacer, 3, and pivot, 4, over the shoulder on

the shaft. Be sure the block assembly is resting

on the snap ring on the opposite end of the shaft.

NOTE: If the spacer and pivot assembly are not

completely down over the shoulder on the shaft as a

result of the block being off the snap ring, the

shimming procedure and motor operation will be

incorrect.

150

Loading...

Loading...