SECTION 10 - ENGINE

10-47

Reassembly

1. Reassemble the piston on the connecting rod as

follows.

2. With a piston heater or the like, heat the piston to

approximately 212° F (100° C). Assemble the

piston to the connecting rod by aligning the set

marks.

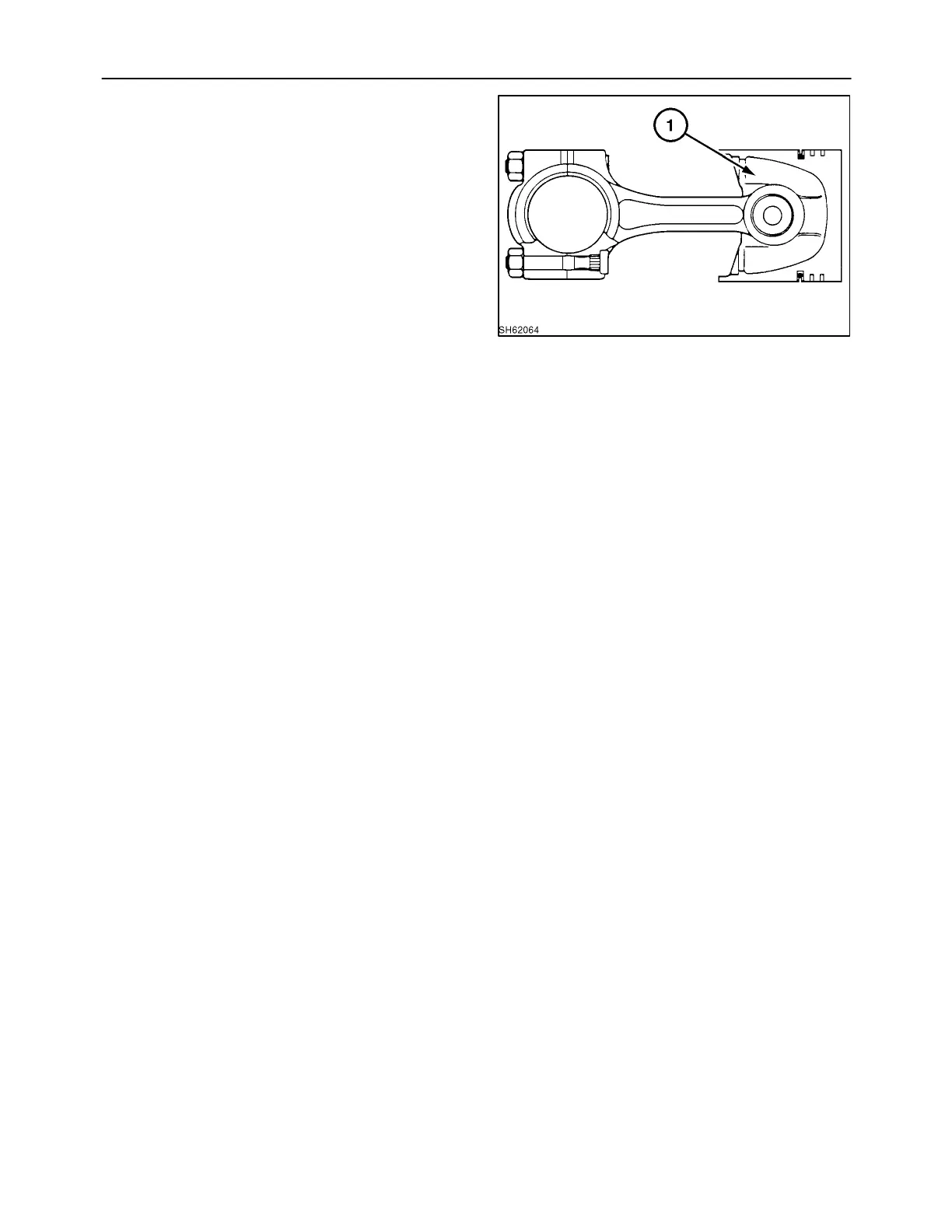

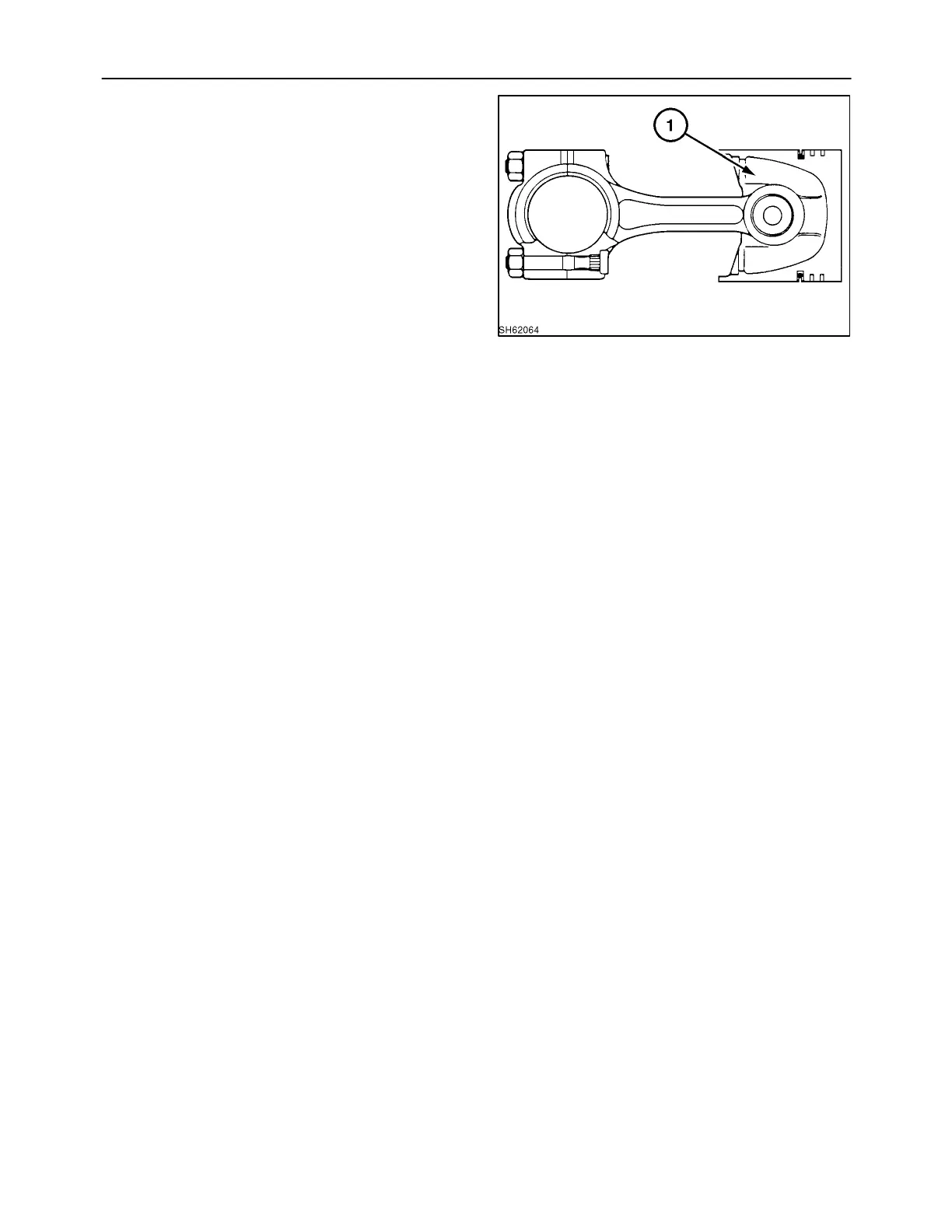

3. Set the “SHIBAURA” marks, or other mark, 1, as

shown. Align the set marks on the connecting

rod.

4. Replace the piston ring on the piston. Position

the scribe mark uppermost.

5. When the connecting rod or piston/piston pin has

been replaced, the difference in the weight of the

assembly (connecting rod plus piston rings)

should not exceed 10 grams between cylinders.

Op. 10 103 10

BEARING HOLDER

Disassembly and Inspection

Center Bearing

1. Remove the bearing holder and check it for

peeling, melting, stepped wear, and other

damage. If it is excessively damaged, replace.

2. Using the plasti-gauge, measure the oil

clearance between the crankshaft center journal

and the bearing.

If the oil clearance is more than the allowable

limit, replace the bearing or grind the crankshaft

center journal and use an undersized bearing

(refer to “Crankshaft”).

Standard Oil Clearance: 0.0017″ - 0 .0040″

(0.044 mm - 0.102 mm)

Allowable Limit: 0.0078″ (0.2 mm)

Crankshaft Center Journal Diameter (mm)

S.T.D.: 2.6755″ - 2.6760″ (67.957 mm - 67.970

mm)

0.010″ (0.25 mm): 2.6656″ - 2.6661″ (67.707 mm

- 67.720 mm)

0.020″ (0.50 mm): 2.6558″ - 2.6563″ (67.457 mm

- 67.470 mm)

65

Loading...

Loading...