SECTION 35 - HYDRAULIC SYSTEM

35-45

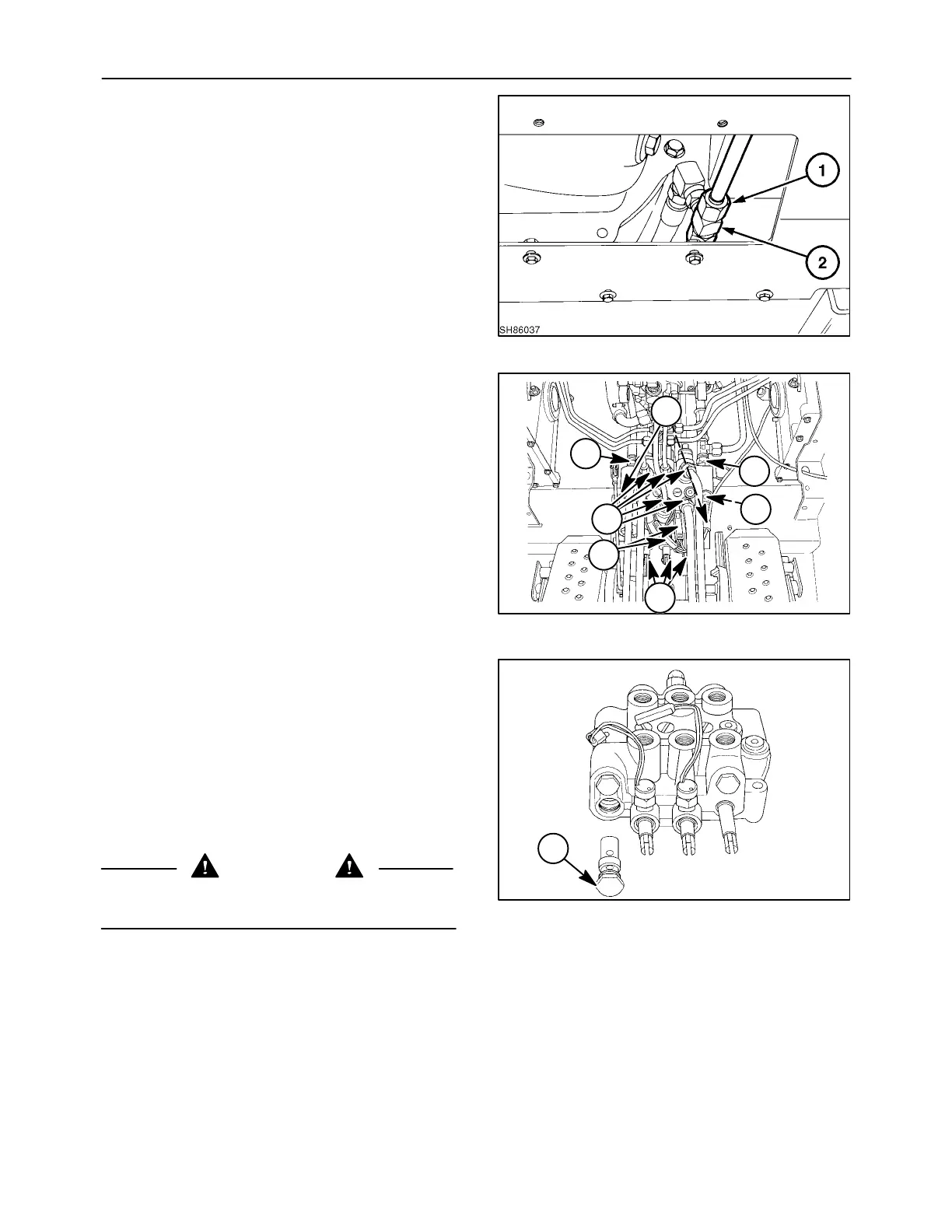

6. Drain the hydraulic reservoir by disconnecting

the return line, 1, at tee, 2, and drain the oil into

a suitable container.

42

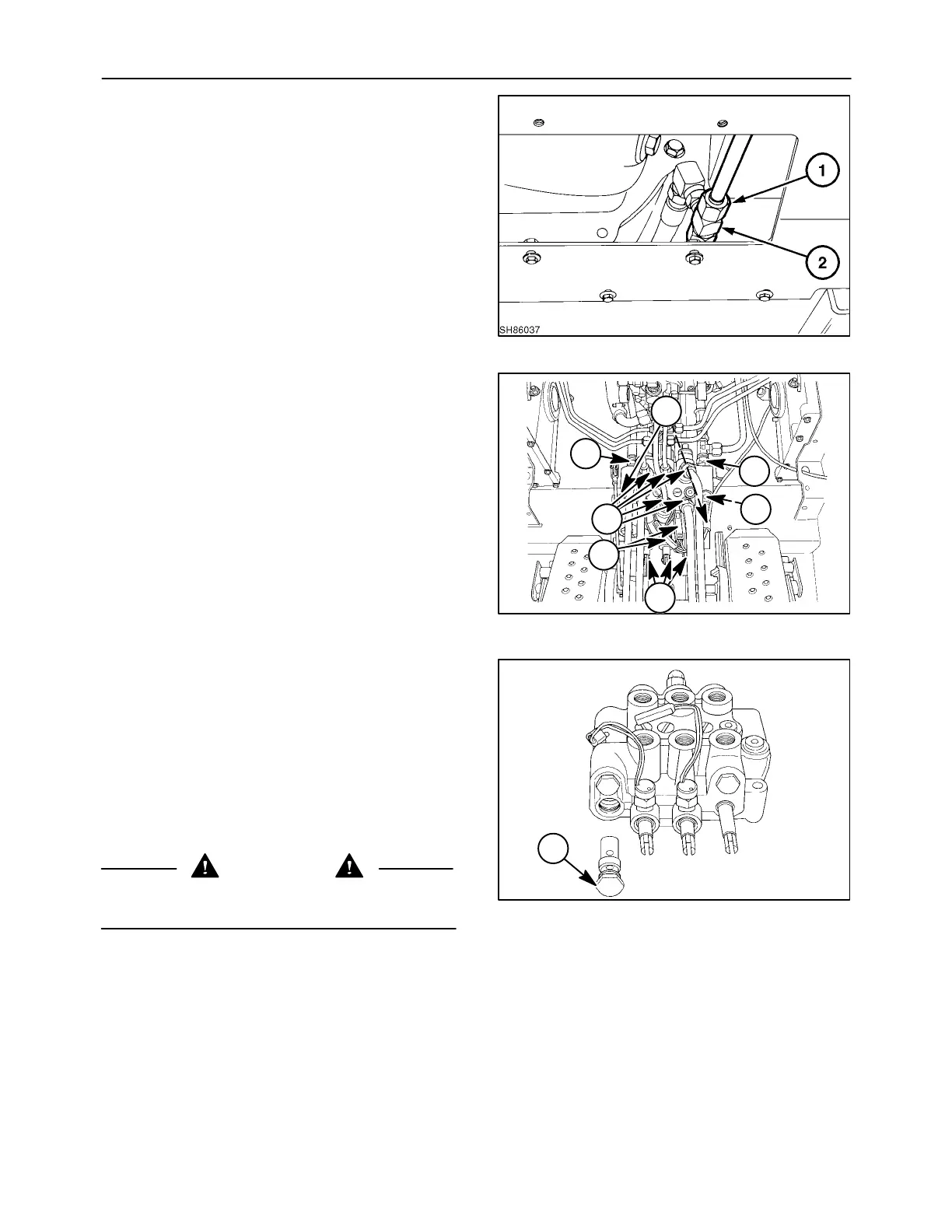

7. Unplug the spool lock solenoids, 1.

8. Remove the pressure line, 2, and return line, 3;

cap both lines to prevent loss of oil and contami-

nation from entering the hydraulic system.

9. Remove the hydraulic lines connected to the

work ports of the control valve, 4, four or six lines,

if unit is equipped with auxiliary boom hydraulics

and cap.

10. Remove the line from the power beyond port, 5,

if equipped with auxiliary hydraulics and cap.

11. Unhook the control linkage from the control valve

spools at 6.

12. Remove the control valve retaining hardware, 7.

Lift the control valve assembly from the loader.

19984464

4

6

2

3

1

7

5

43

Op. 35 724 54

DISASSEMBLY AND INSPECTION

Main System Relief Valve

The non-serviceable, non-adjustable, cartridge- type

main system relief valve, 1, is set at 170 - 177 bar

(2500 - 2600 PSI). The relief valve should not be re-

placed with a valve of a higher pressure setting, as

structural damage to the boom and/or main frame or

internal damage to hydraulic system may occur.

CAUTION

Component failure from high hydraulic pressure

could result in injury.

19984465

1

44

Loading...

Loading...