SECTION 82 - FRONT LOADER (BOOM AND MOUNTING PLATE)

82-9

Op. 82 100

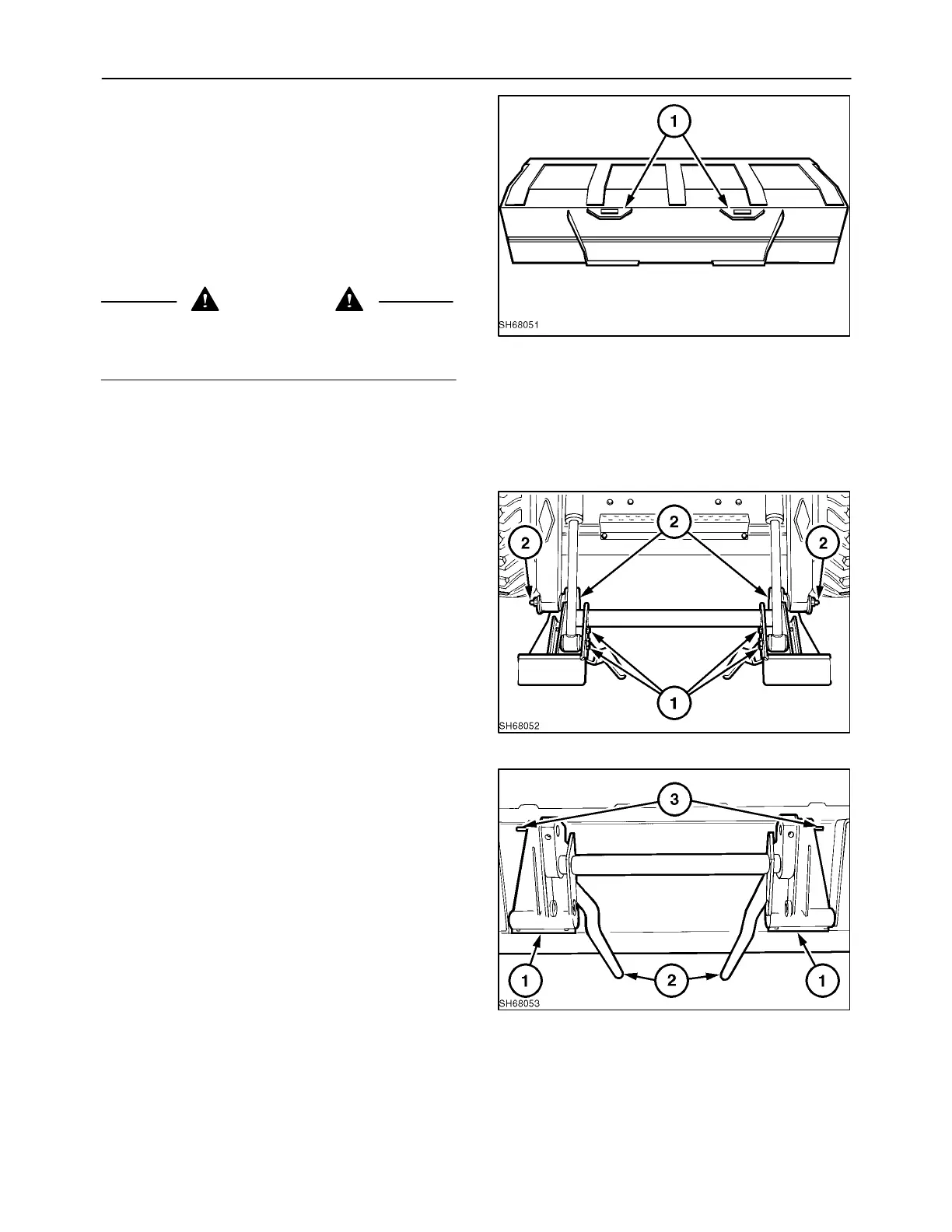

BUCKET LATCH PLATE INSTALLATION

PROCEDURE

1. Remove the bucket from the loader before weld-

ing to prevent damage to the loader electrical

system.

Material to be welded is low carbon, grade 50

steel; use welding rods marked 6011 or compa-

rable.

CAUTION

Good quality welds are necessary for new plates

to be properly retained. Use a professional weld-

er if required.

2. Turn the bucket over and support it about

305 mm (12″) off the floor.

3. Cut the old lower retaining plates, 1, off the buck-

et and grind the area flat.

15

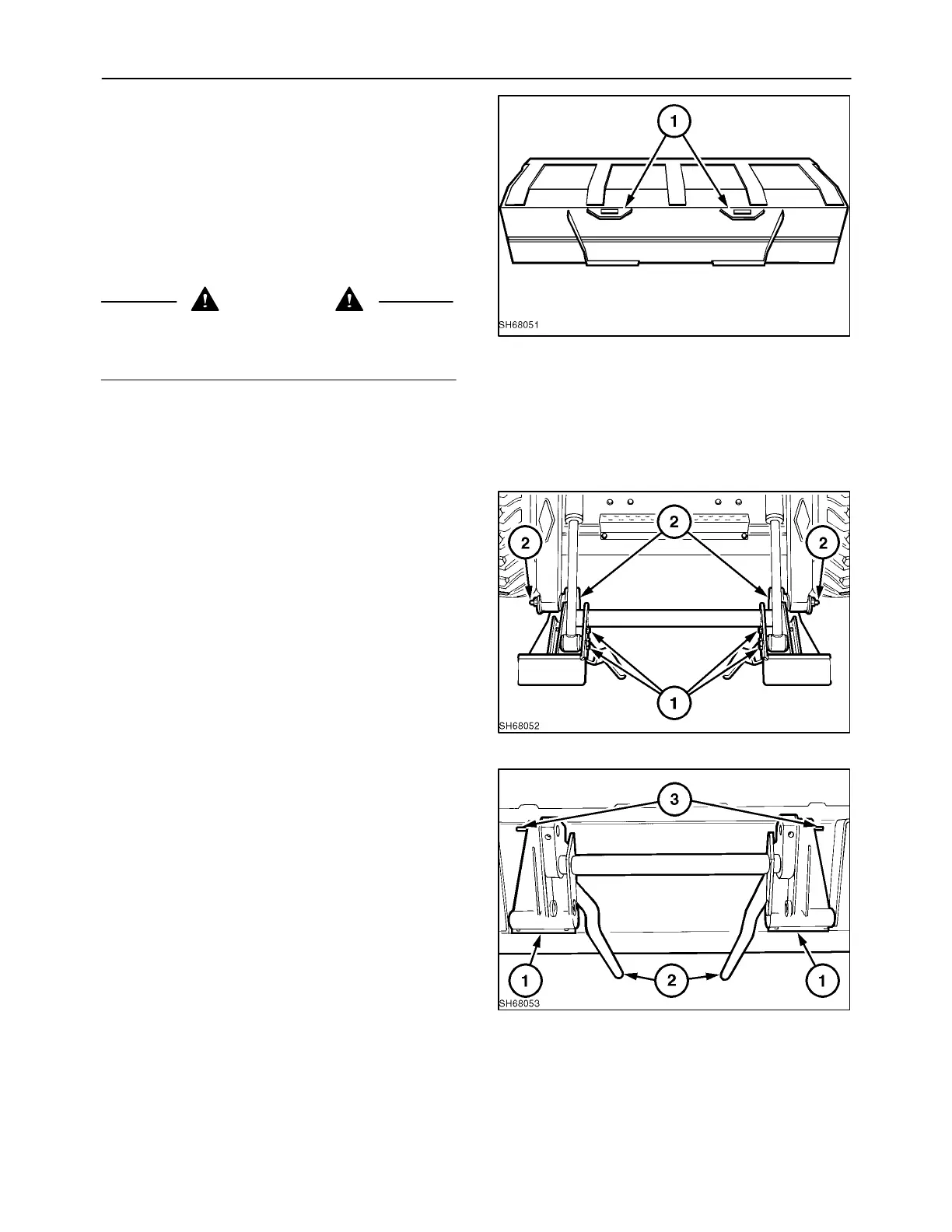

4. For locating the new lower attaching plates, re-

move the quick-attach plate from the loader

boom. To remove the plate from the boom, re-

move the cylinder pins, 1, and the pivot pins, 2.

16

5. Rest the attaching plate in the saddle area, 1, of

the bucket with the latch handles in the unlatched

position as shown at 2. Put two 152 mm (6″) long

pieces of 4.8 mm (3/16″) square key stock at 3,

to position the attaching plate properly against

the back of the bucket.

17

Loading...

Loading...