SECTION 35 - HYDRAULIC SYSTEM

35-59

HYDRAULIC SYSTEM PUMP PARTS

INSPECTION

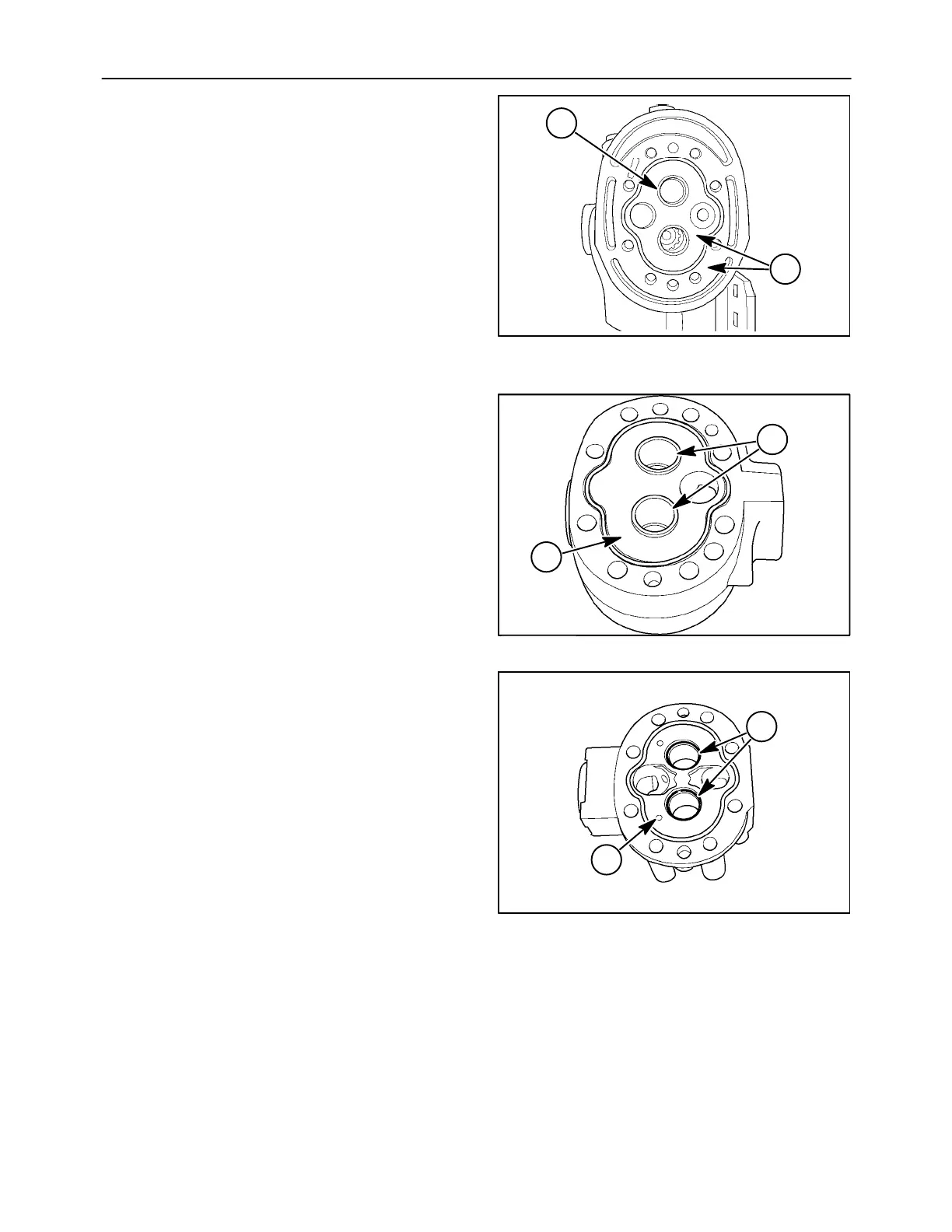

1. Inspect the pump mounting plate for excessive

wear. The oil grooves in the bushings, 1, should

be line up with the dowel pin holes and be

approximately 180° apart. If the bushing oil

grooves are not positioned as noted, the bush-

ings have turned in the plate - the plate should be

replaced.

The bushings in the plate should be 3.20 mm

(0.126″) above the surface of the plate. Replace

the plate if the I.D. of the idler gear bushing ex-

ceeds 19.2 mm (0.755″).

2. Check the seal areas, 2, for scratches or damage

that could prevent a good seal.

19997782

1

2

78

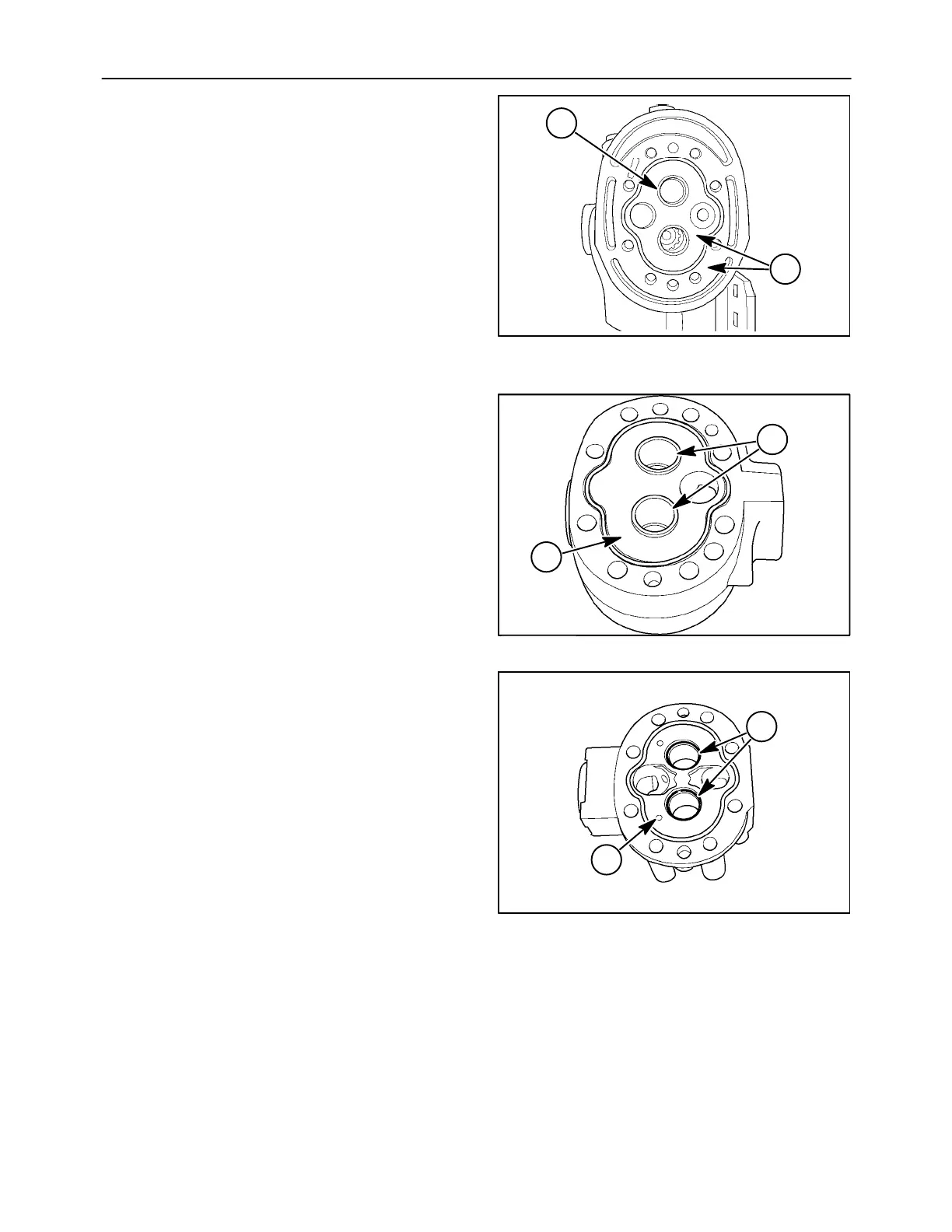

3. With High Flow - Inspect the pump back plate for

excessive wear. The oil grooves in the back plate

bushings, 1, should be at approximately 37° to

the pressure side. If the bushing oil grooves are

not positioned as noted, the bushings have

turned in the plate. The plate should be replaced

under this condition.

The bushings in the plate should be 3.20 mm

(0.126″) below the surface of the plate. Replace

the back plate if the I.D. of a bushing exceeds

19.2 mm (0.755″).

Check for scoring on the face of the back plate,

2. Replace the back plate if wear exceeds 0.038

mm (0.0015″).

19997786

2

1

79

4. Without High Flow - Inspect the pump back plate

for excessive wear. The oil grooves in the back

plate bushings, 1, should be at approximately

37° to the pressure side. If the bushing oil

grooves are not positioned as noted, the bush-

ings have turned in the plate. The plate should be

replaced under this condition.

The bushings in the plate should be 3.20 mm

(0.126″) below the surface of the plate. Replace

the back plate if the I.D. of a bushing exceeds

19.2 mm (0.755″).

Check for scoring on the face of the back plate,

2. Replace the back plate if wear exceeds 0.038

mm (0.0015″).

19997761

2

1

80

Loading...

Loading...