SECTION 35 - HYDRAULIC SYSTEM

35-61

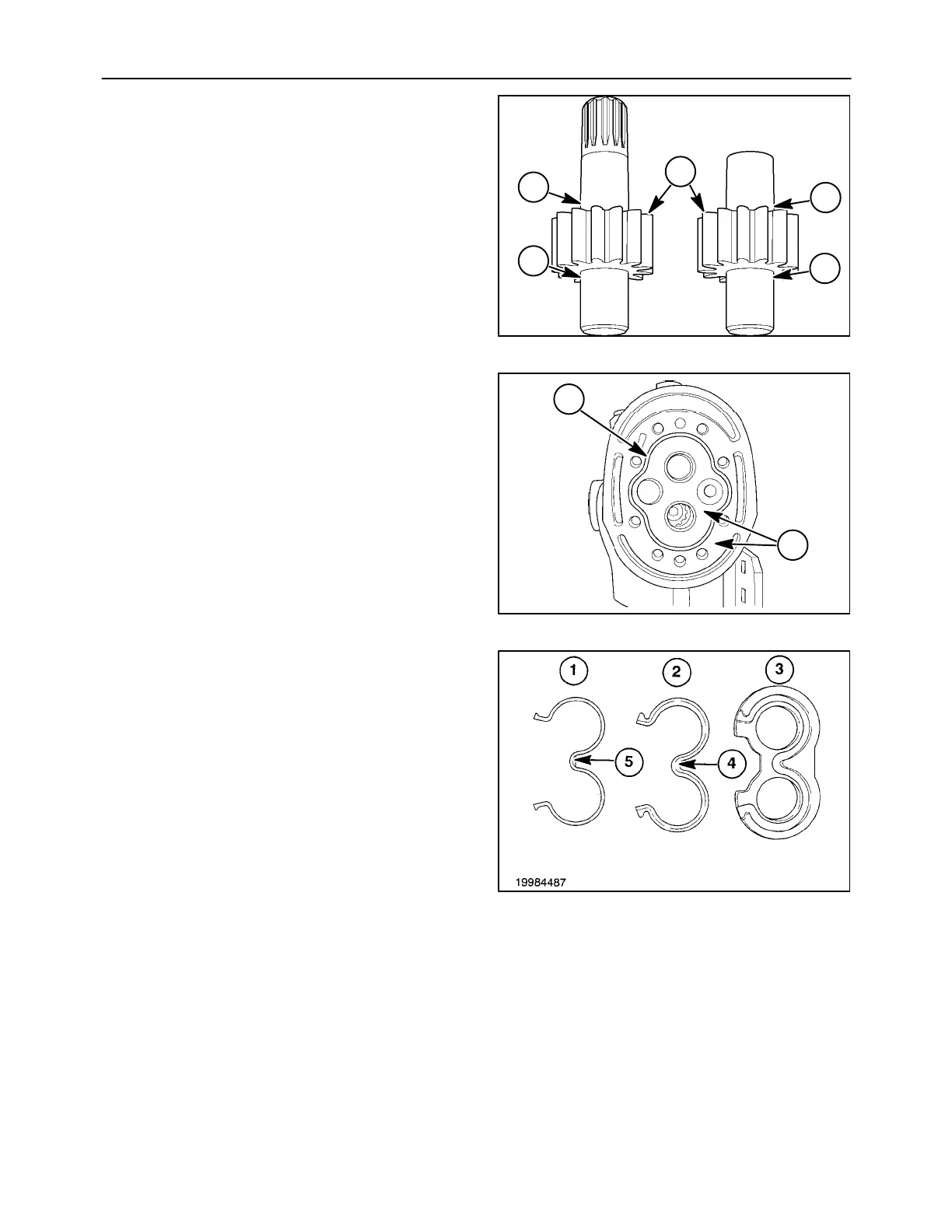

8. Without High Flow - Inspect the pump gear teeth,

1, for excessive wear.

The gear shaft assemblies should measure

greater than or equal to 0.748″ (19.0 mm) in the

bushing area, 2. LS160 gear should be at least

22.56 mm (0.888″) wide. LS170 gears should be

at least 22.76 mm (1.014″) wide. Replace the

gears if they do not meet specifications.

NOTE: If replacement of the gear assemblies is

necessary, the gear assemblies should be replaced

in pairs.

19997814

2

1

2

2

2

84

HYDRAULIC SYSTEM PUMP

REASSEMBLY/ INSTALLATION (WITHOUT

HIGH FLOW)

NOTE: If installing a new pump, refer to “New

Hydraulic System Pump Installation (Without High

Flow)” below.

1. Coat all parts with a thin coat of petroleum jelly or

oil to aid in reassembly.

2. Clean the mounting plate surface and hydrostat-

ic pump housing thoroughly and install a new O

ring, 1.

19997782

1

2

85

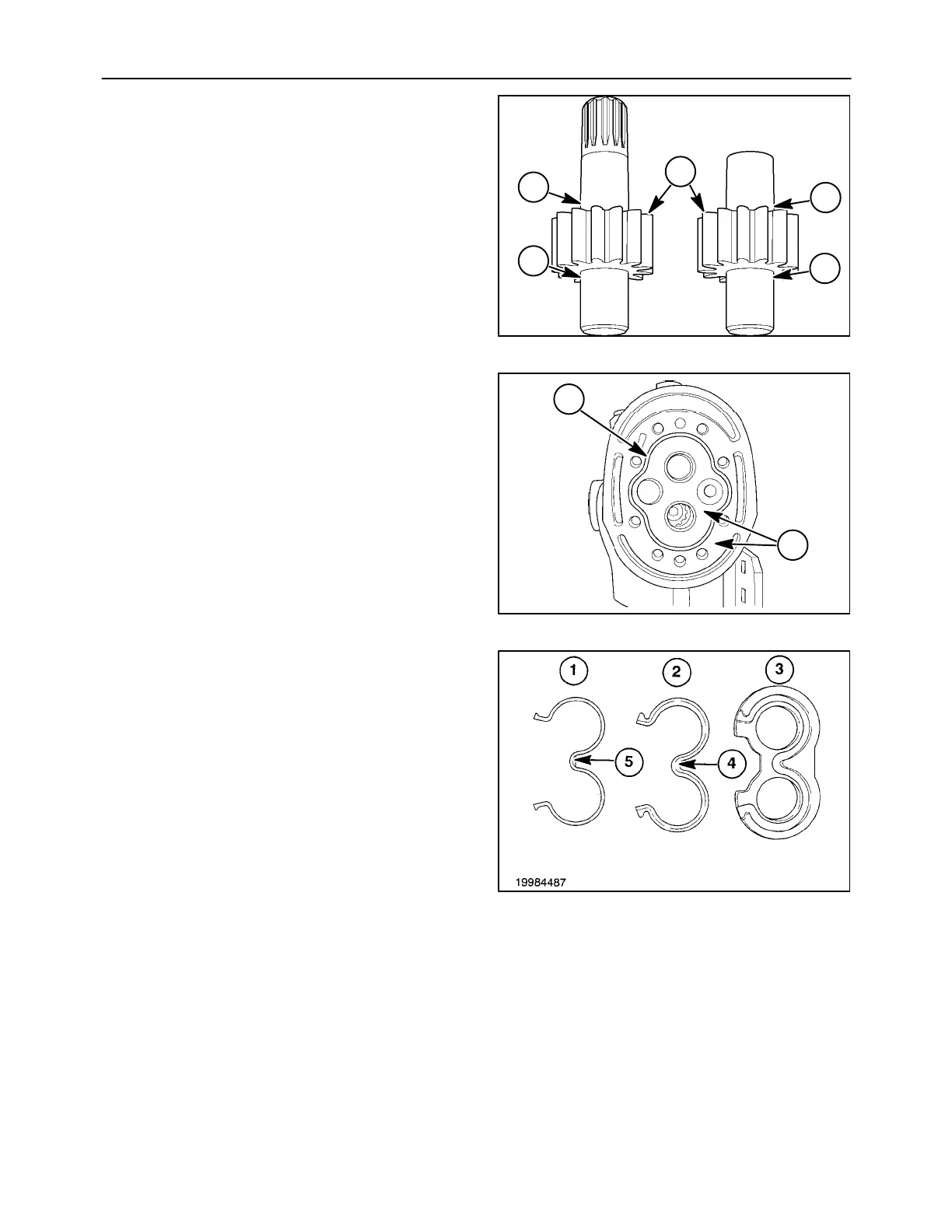

3. Install the seal, 1, and backup gasket 2, on the

wear plate, 3. BE SURE that the flat area, 4, on

the gasket AND seal, 5, are properly aligned and

lay flat when installed in the wear plate.

86

Loading...

Loading...